Bipolar Plates

Metallic bipolar plate manufacturing service for fuel cells and electrolysers.

Request Pricing Application NoteWe offer a market-leading bipolar plate manufacturing service, working in collaboration with leading sustainable energy providers developing fuel cells and electrolysers for hydrogen production, transportation, power generation and more.

WHAT ARE BIPOLAR PLATES?

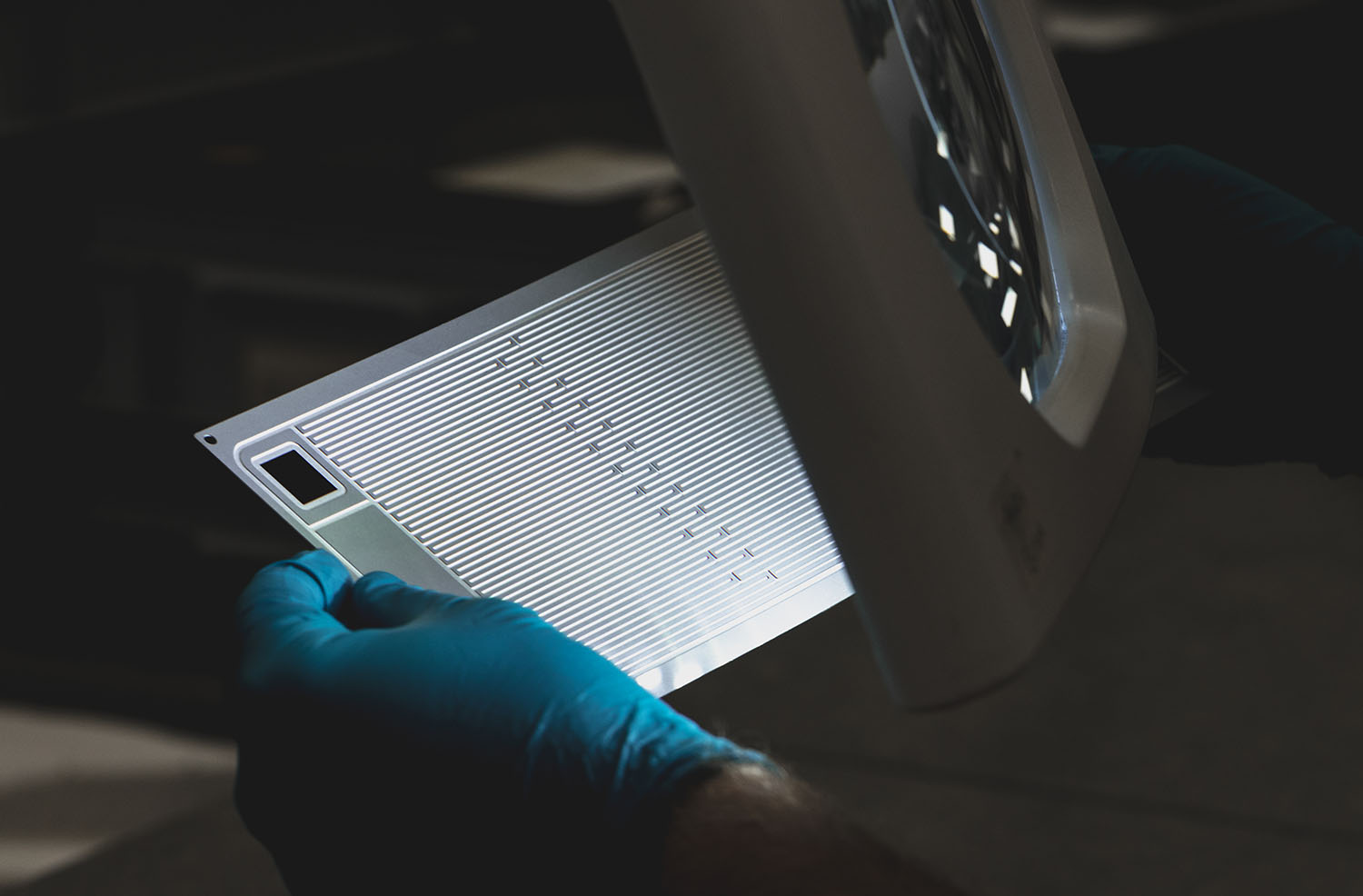

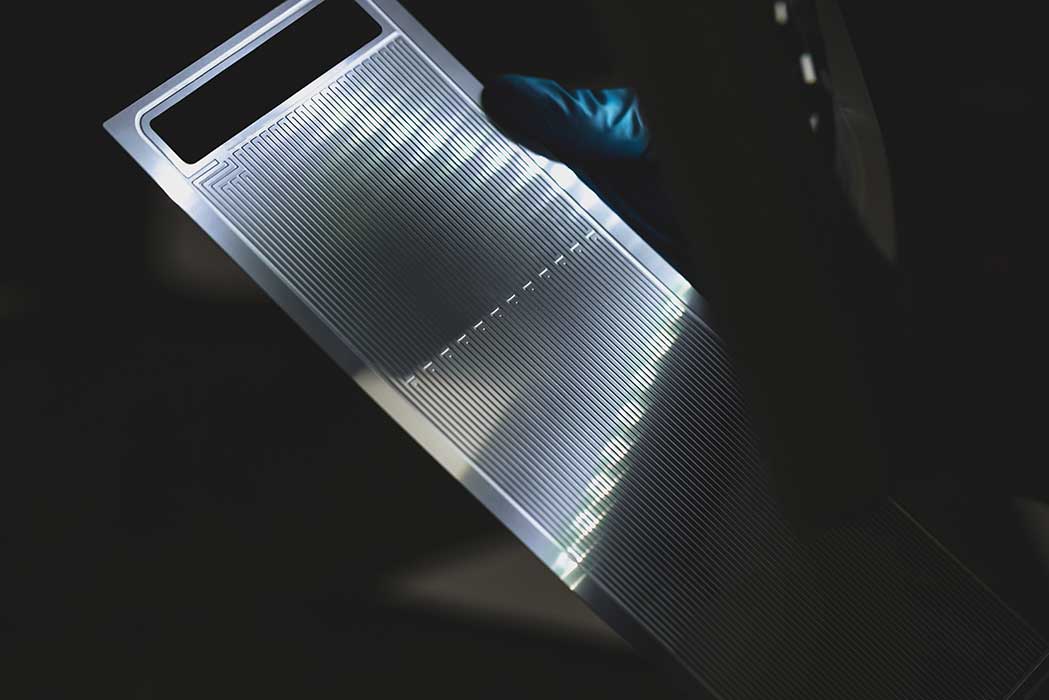

Bipolar plates are a key component of proton exchange membrane, alkaline and solid oxide fuel cells and electrolysers. They are machined with complex flow fields or channels that, when stacked, distribute gas and air, as well as conduct electrical current from one cell to the next.

METALLIC BIPOLAR PLATE MANUFACTURING

Although stamping and hydroforming can be used to produce metallic bipolar plates, these processes can have limitations, such as compromising planarity (flatness) and introducing stresses and burrs. Presswork tooling can also be slow, expensive and uneconomical to produce, especially during prototyping.

PHOTOCHEMICAL ETCHING BIPOLAR PLATES

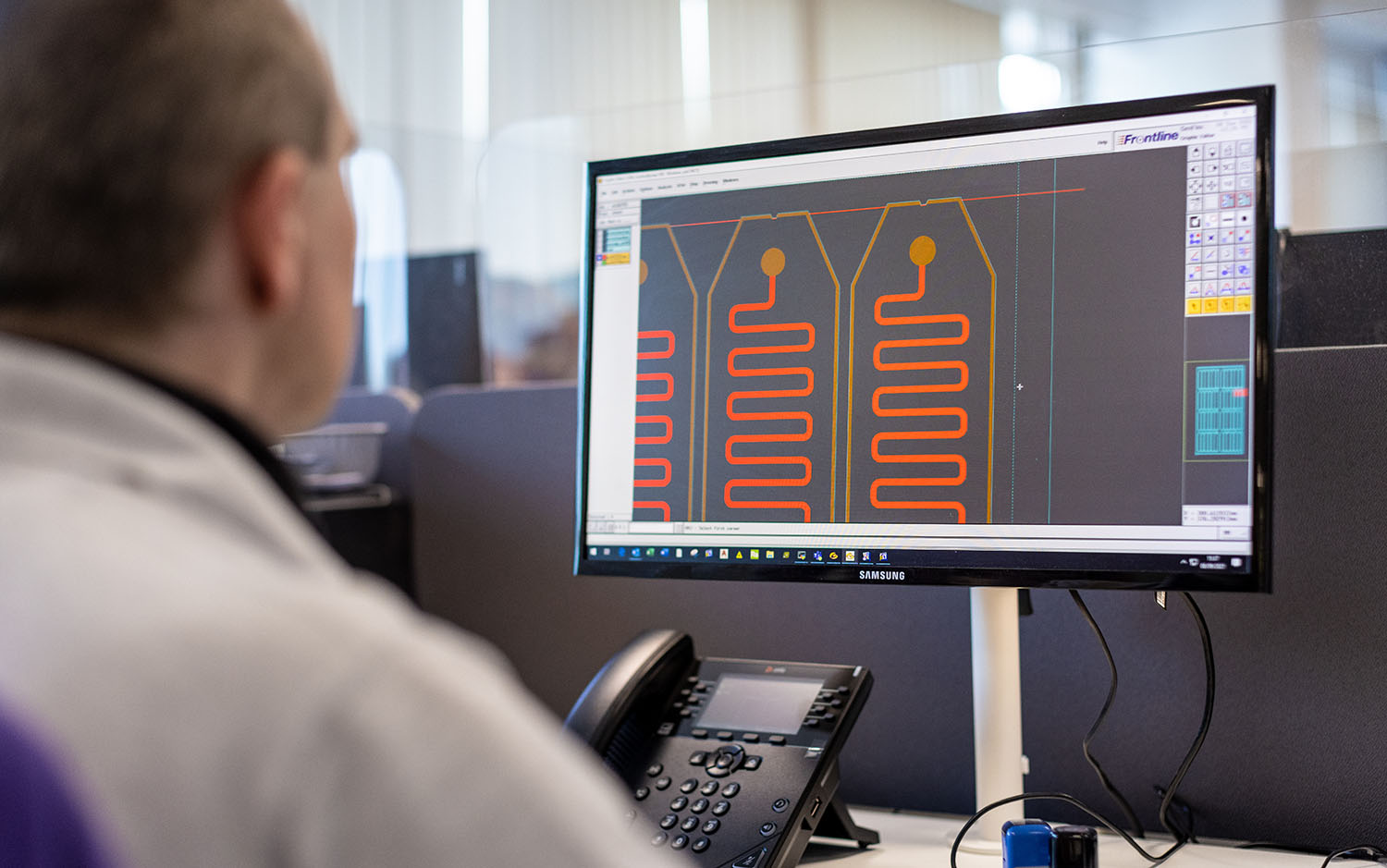

Our market-leading chemical etching service uses digital tooling, offering a cost-effective and efficient method that enables easy adaptation and optimisation of designs in short lead times.

Benefits

No expensive hard tooling

Burr-free, stress-free and flat

High channel accuracy

Wide range of metals

COMPLEX, BURR & STRESS-FREE DESIGNS

Chemical etching provides the unique advantage of simultaneous removal of metal, allowing for the creation of intricate channels or flow fields on both sides of the plate. Unlike other methods such as bipolar plate stamping or hydroforming, chemical etching avoids introducing mechanical stress or burring, which can potentially compromise stack bonding and overall performance. This ensures the integrity of the etched plate while maintaining optimal functionality and performance without any detrimental effects.

Bipolar plates application note

Learn more about the benefits of chemical etching bipolar plates for fuel cells and electrolysers.

Download