Energy

Supporting net-zero technology by supplying fast, accurate precision-etched components.

Contact Us BrochurePrecision Micro plays an active role in supporting net-zero technology by supplying precision-etched components that enable a range of applications, such as hydrogen generation and storage, carbon capture, renewable energy systems, hydrogen drivetrains, electric vehicles and more.

Faster time-to-market

Constant innovation and evolving technologies drive the need for rapid development and testing of new component designs for next generation energy applications.

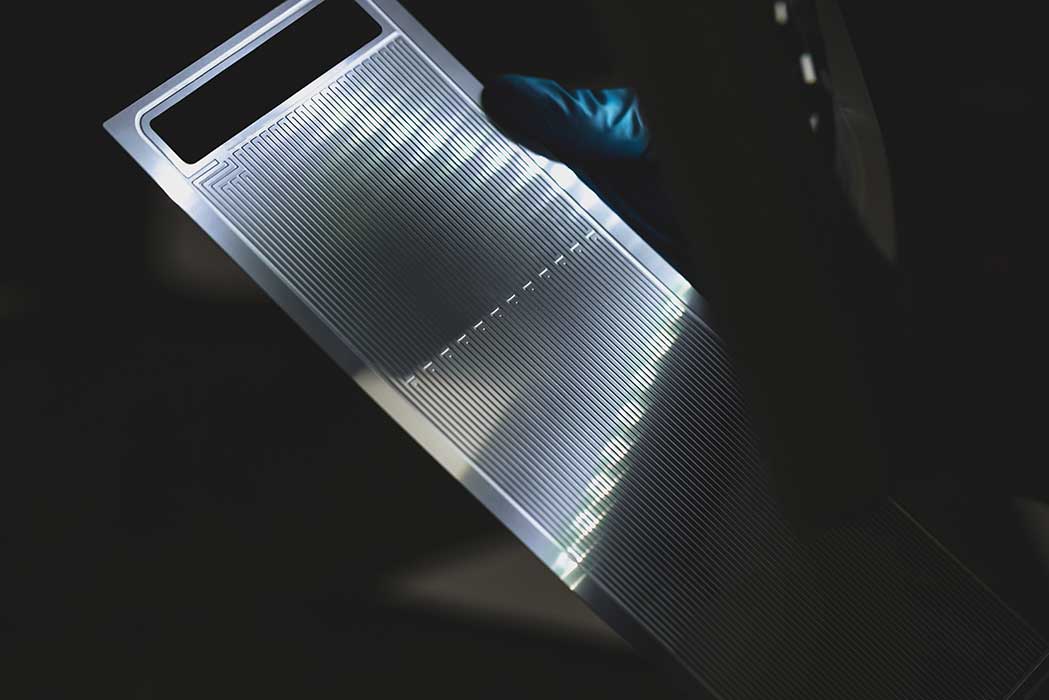

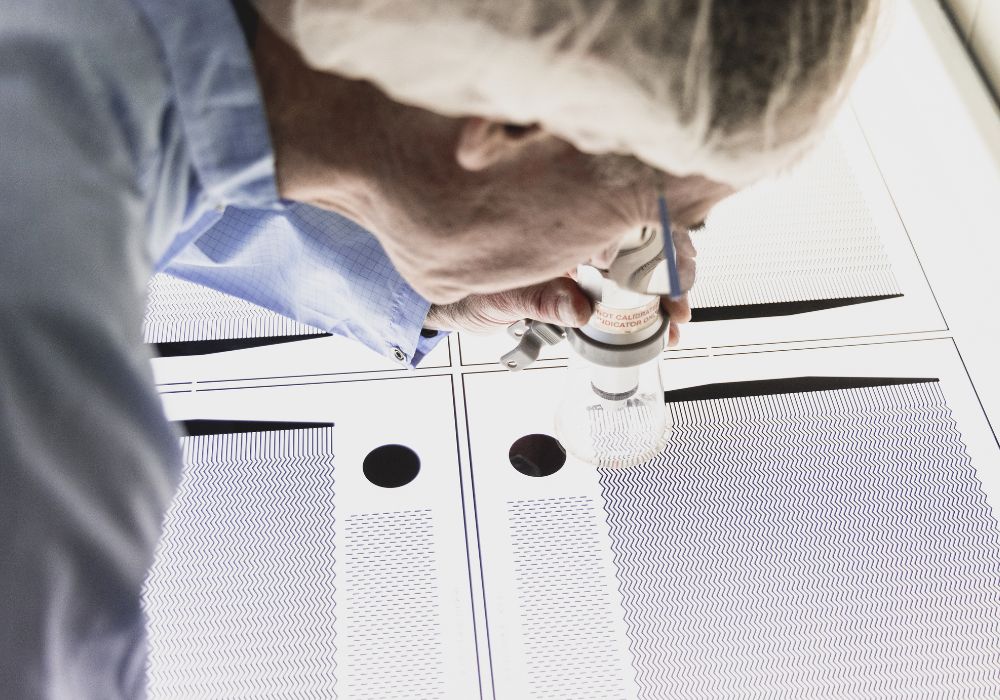

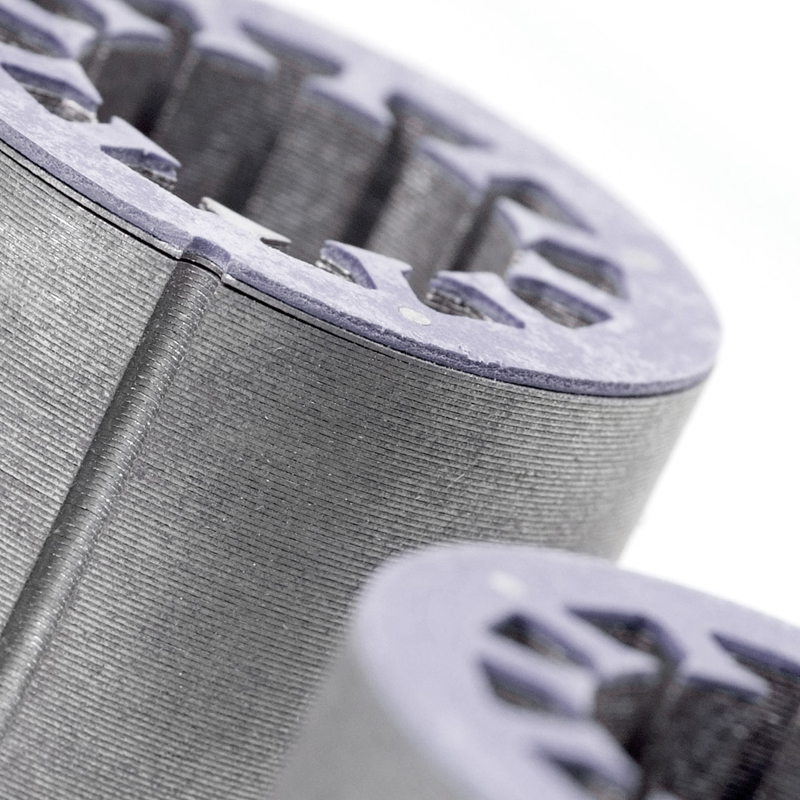

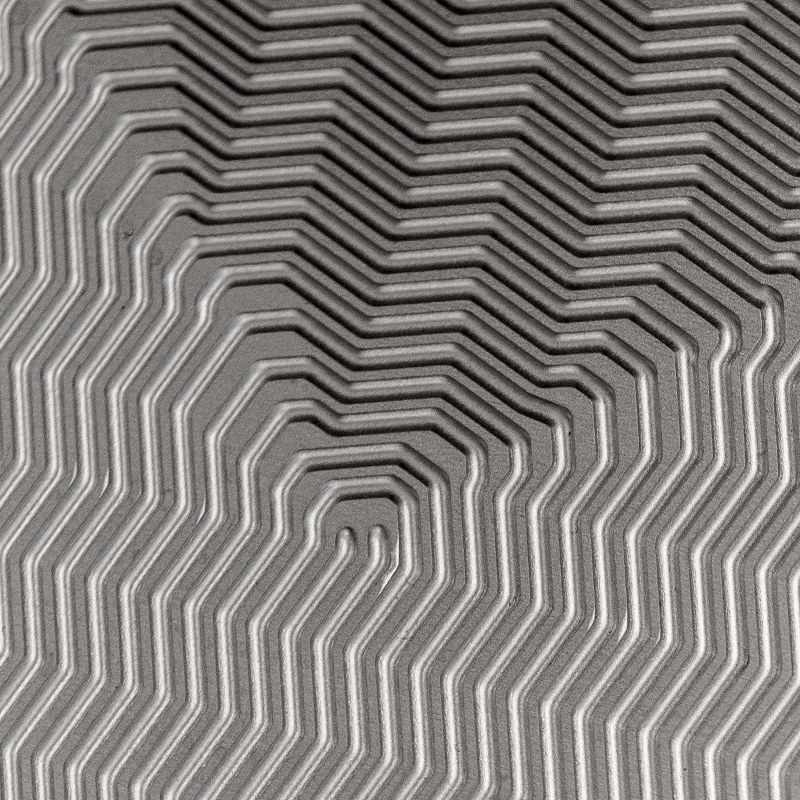

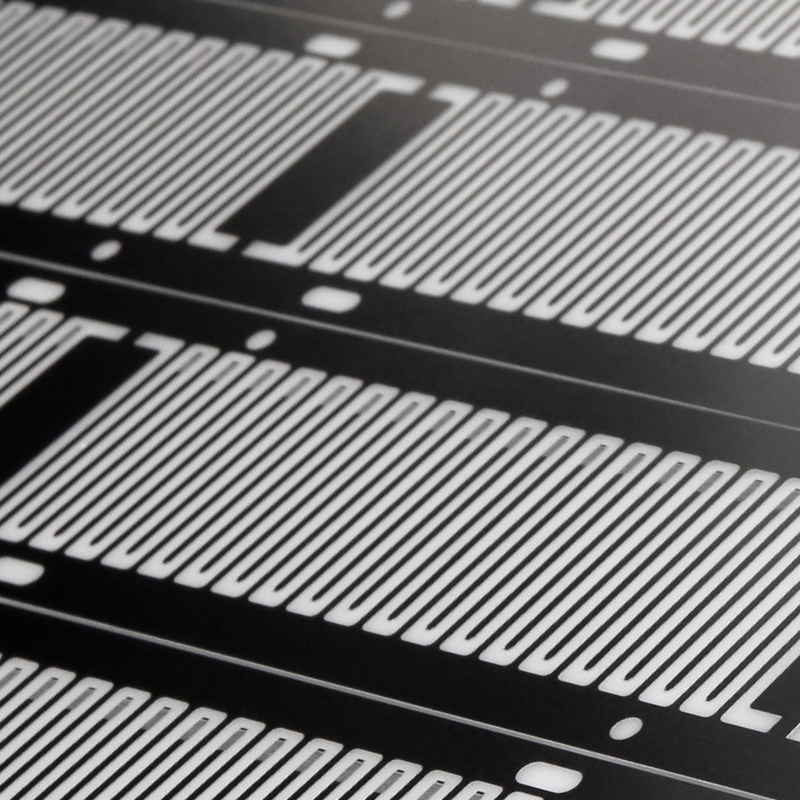

Chemical etching accelerates prototyping through the use of affordable digital tooling, allowing for efficient design iterations and faster time-to-market. Whether its intricate channel arrays for hydrogen electrolysers or high-performance interconnects for EV battery systems, chemical etching outperforms traditional sheet metal machining by producing smaller, intricate parts without the constraints of traditional sheet metal machining.

Benefits

Low-cost tooling and rapid prototyping

Higher complexity, accuracy and precision

100% burr and stress-free components

Widest range of metals

Energy components

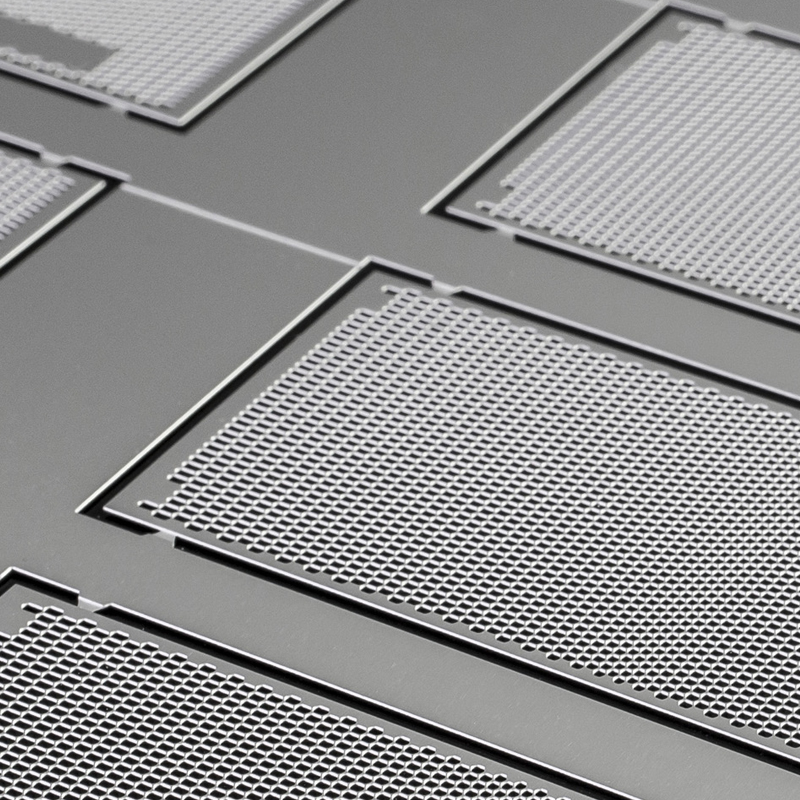

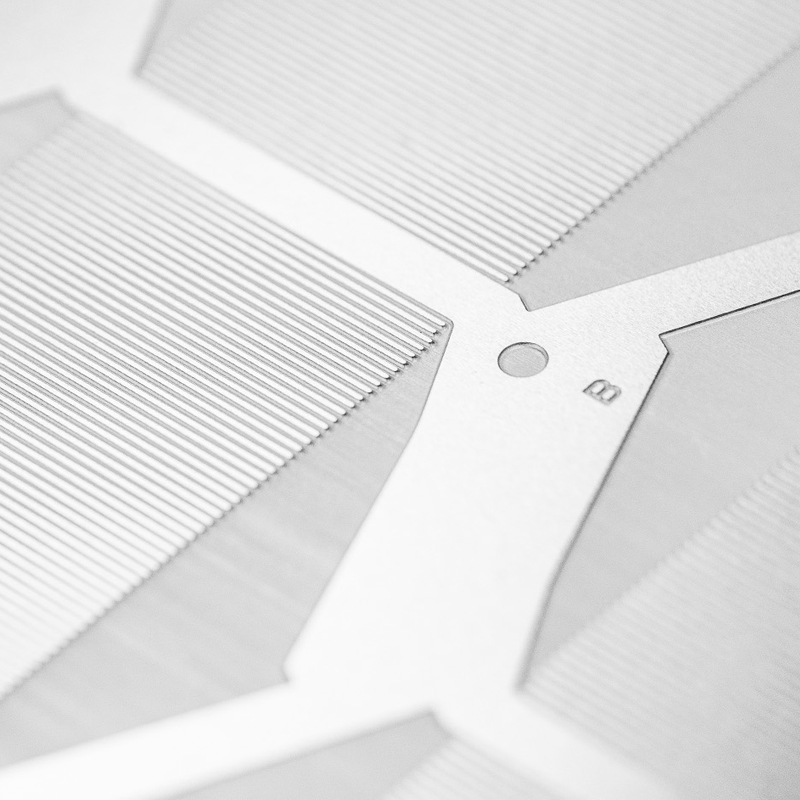

We manufacturer a wide range of precision metal components for the energy sector, including bipolar plates, gas separation membranes and electric motor laminations. Alongside chemical etching, we provide additional services including diffusion bonding, forming and plating, catering to the diverse requirements of our customers.

Electric Motor Laminations

Filters, Screens & Sieves

Custom Metal Shims

Bipolar Plates

Printed Circuit Heat Exchangers

Electrical Connectors

Material versatility

Chemical etching demonstrates exceptional compatibility with a diverse array of metals, including corrosion-resistant stainless steel, conductive copper, and various nickel alloys. Unlike conventional machining techniques, this process effectively overcomes the limitations encountered when working with materials that possess hard, soft, or brittle properties.

Download Accreditations

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download