Aluminium Etching

AS 9100 and IATF 1694-accredited aluminium etching service.

Contact UsOur aluminium etching process is highly repeatable and consistent, offering a cost-effective and versatile manufacturing alternative to stamping, laser cutting and waterjet cutting.

How We Etch Aluminium

Machining aluminium and its alloys has consistently presented challenges for both traditional processes and chemical etching. During etching, aluminium releases heat energy, leading to the formation of rough, granular edges. The material is also extremely reactive with certain chemical etchants, requiring meticulous control to ensure precise parts.

At Precision Micro, we have pioneered a robust, proprietary solution for etching aluminium and its alloys, producing cleaner edge profiles with enhanced accuracy and efficiency. Our chemical etching process also offers exceptional control and accuracy, ensuring optimal part performance.

Complex Geometries Without The Cost

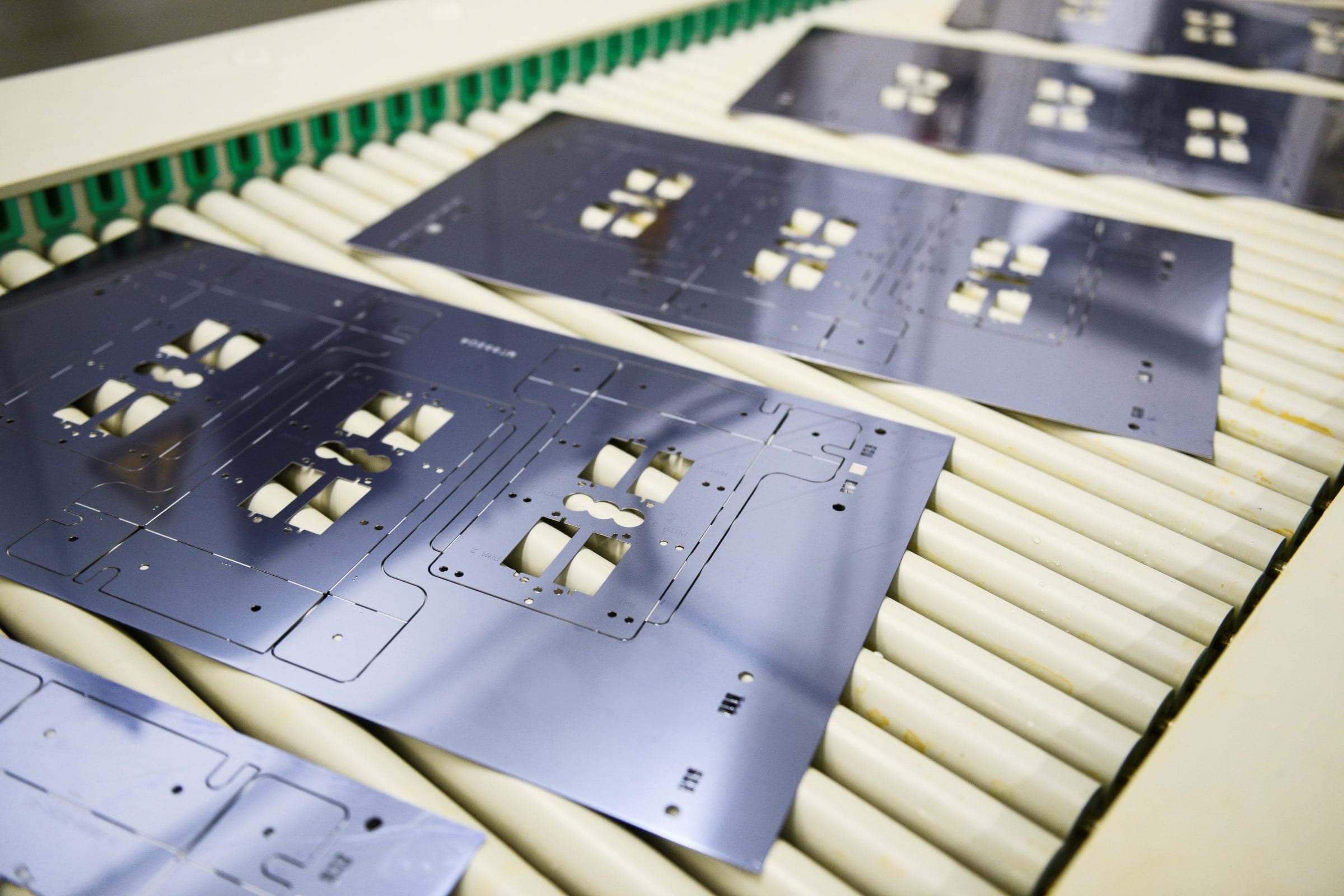

We use low-cost digital tooling to provide a rapid, cost-effective aluminium etching service. Using digital tooling also enables us to etch intricate, complex geometries without cost penalty and tight tolerances with accuracy to ±0.020mm. Additionally, prototyping is accelerated, allowing for efficient design iterations and faster time-to-market, providing an ideal alternative to traditional machining methods such as stamping and laser cutting.

Aluminium Grades Suitable For Chemical Etching

Our aluminium etching extends from pure aluminium to a wide range of aluminium alloys, including 3003, 5052, 6061 and 7075. We also work with aluminium bronze and aluminium polyimide film which is suitable for flexible electronics applications.

| Material | Grades/types |

|---|---|

| Aluminium | All grades |

| Aluminium polyimide film | N/A |

| Aluminium bronze | CA102 |

Etched Aluminium Components

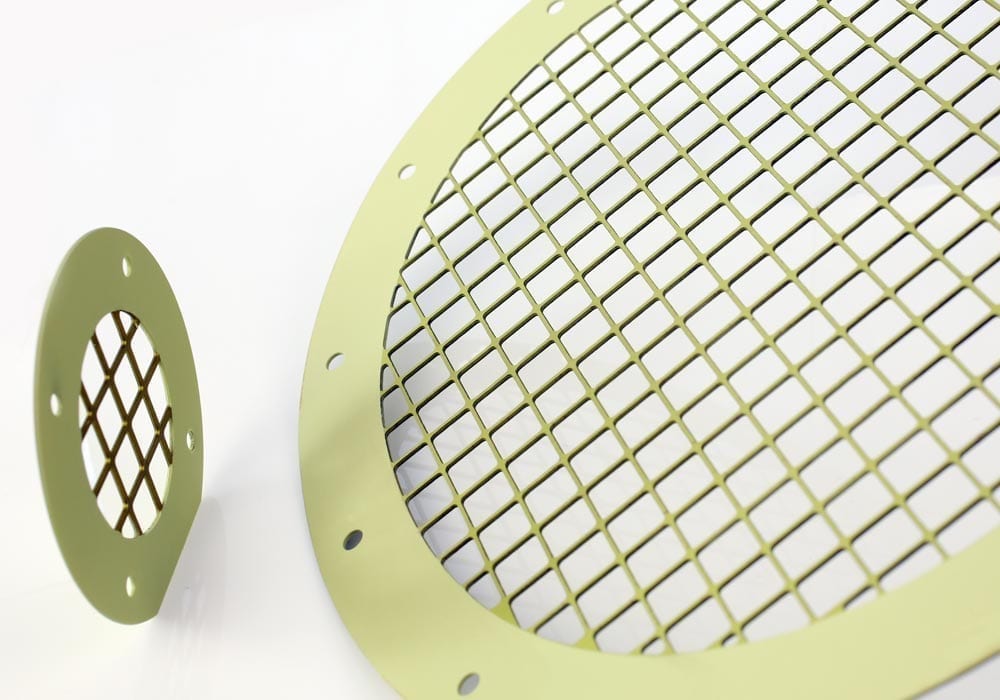

Precision Micro is an AS 9100 and IATF 16949-accredited aluminium etching supplier, specialising in etching aluminium components for automotive and aerospace applications, as well as other high-tech industries. Aluminium’s lightweight properties enhance fuel efficiency and reduce carbon emissions, while its strength and durability make it an ideal material to withstand the rigorous demands of these sectors.

Some of the components we produce for these industries include:

- Durable, lightweight helicopter intake grilles which withstand and maintain their properties in extreme conditions.

- Heater plates stacked and utilised in aircraft dehumidifiers with low initial set-up costs and etched with precision channels to improve airflow.

- Compact, shaped heat exchanger plates with the capability to be etched with complex channels and pin arrays, reducing footprint and improving the thermal management of aircraft engines.

- Aluminium car interior components such as dials, dashboard inlays and instrument covers that can be machined with high-definition logos, surface textures and profiles.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download