PCB Shielding Cans

With more than six decades of global supply in PCB board level shielding, we specialise in producing custom PCB shielding cans for diverse electronics applications using photochemical etching technology.

EMI/RFI Shielding at PCB level

EMI shielding, also referred to as electromagnetic shielding, RFI shielding or EMC shielding, involves employing manufacturing techniques and materials to safeguard against interference from external electromagnetic signals, while also preventing internally generated interference from nearby components.

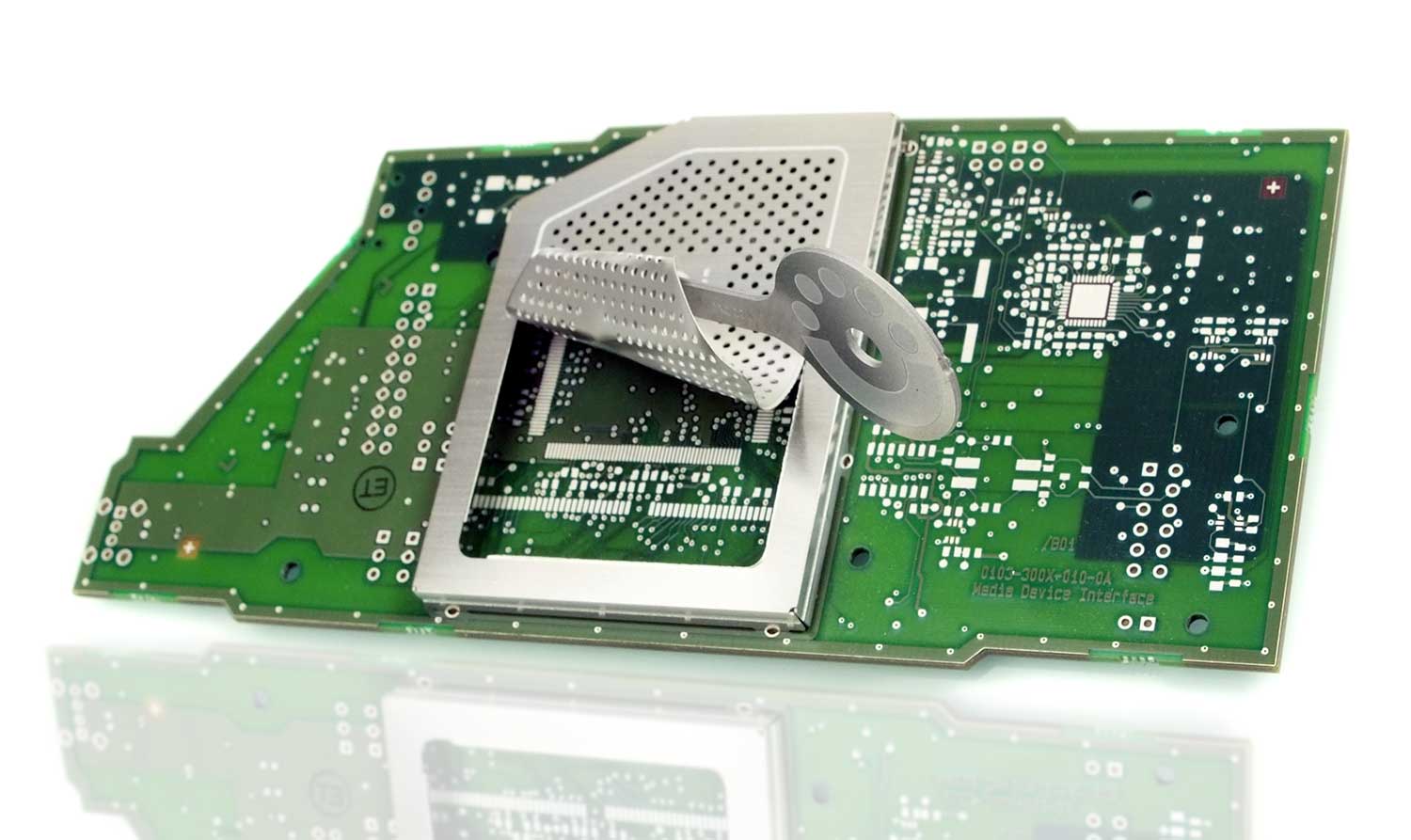

In the context of PCBs, known as Board Level Shielding (BLS), shielding is typically implemented through the use of PCB shield cans or enclosures made from conductive or magnetic materials. These shielding solutions effectively isolate electrical devices from their surrounding environment, ensuring optimal performance and minimal interference.

Chemical etching PCB shielding cans

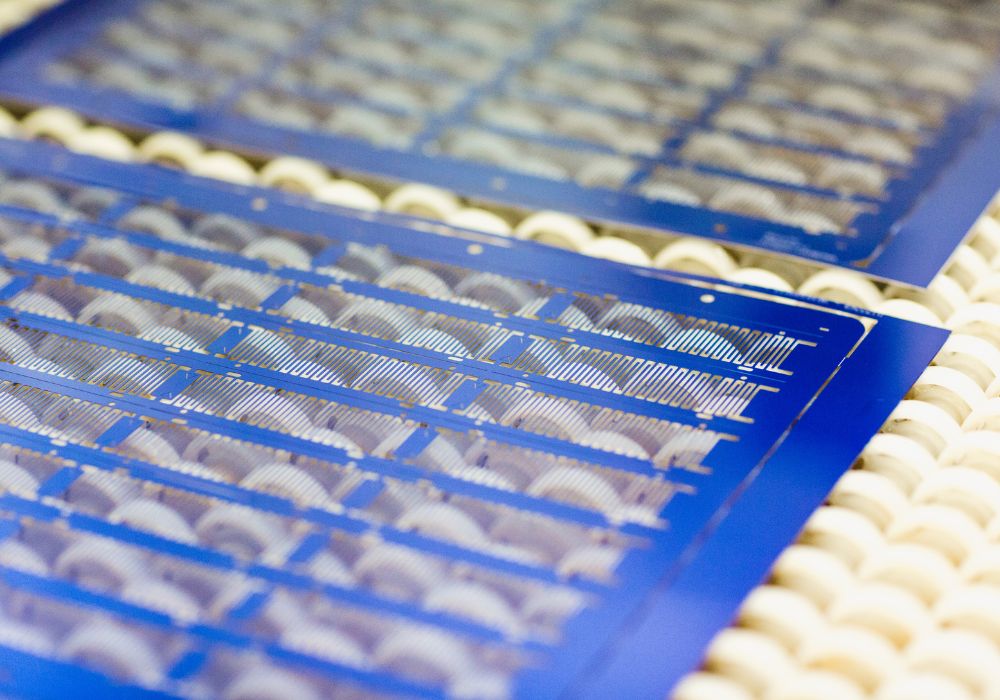

Our industry-leading chemical etching service provides numerous advantages that enhance functionality and reduce costs, making it the preferred choice for manufacturing EMI/RFI shield cans in prototype to production volumes. Through chemical etching, the time-consuming process of tooling or mold preparation is eliminated, resulting in shorter lead times and faster production cycles.

Additionally, this method offers exceptional design flexibility, allowing for the seamless integration of features like ventilation and access holes, fold lines for hand forming and part numbers and logos without incurring any additional cost.

Benefits

Low cost tooling

Fast delivery

Custom features at no additional cost

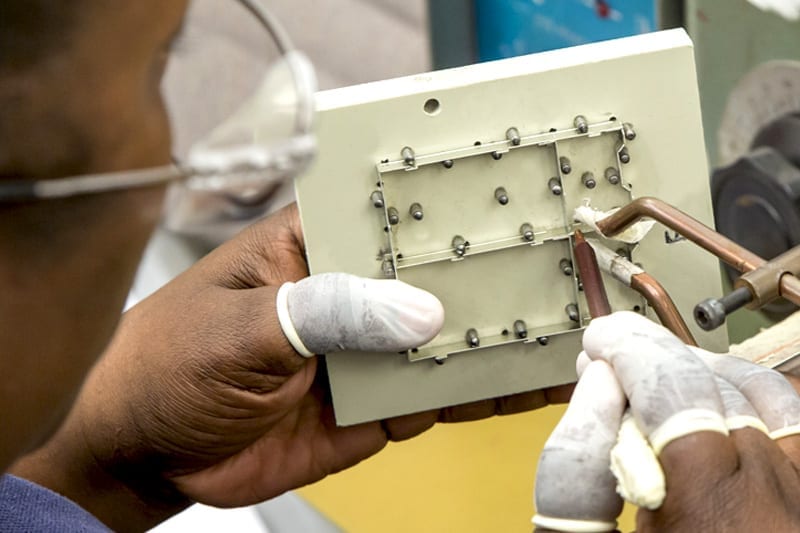

In-house forming and finishing

Materials & post-process services

When it comes to materials for RF shield cans, nickel silver stands out as the most cost-effective choice. Not only can it be easily soldered, but it also resists oxidation and does not require additional plating. In addition to nickel silver, we also offer standard materials like brass and mild steel, readily available in our stock.

To ensure a comprehensive service, we offer in-house capabilities that encompass forming, assembly, spot welding and plating. Our plating options include tin, silver, nickel and gold, enabling us to meet diverse customer requirements and deliver RF shield cans of exceptional quality.

PCB Shielding Cans Application Note

Learn how chemical etching can offer a more cost-efficient PCB shielding can manufacturing service.

Download