Additional Services

Forming, finishing and surface treatments.

Contact UsBelow is a selection of in-house and subcontract forming, finishing and surface treatment options we offer to complement our chemical etching service.

Precision Forming

We provide manual and semi-automatic precision forming using standard, modular and custom form tools. When possible, we incorporate bend lines into etched components, eliminating the need for hard form tooling. Additionally, we offer in-house spot welding for formed, 3-D components that require a permanent connection.

Electropolishing & passivation

We offer both passivation and electropolishing to enhance component corrosion protection. Passivation purifies the component surface and forms a protective metal oxide coating, preserving the base metals integrity without altering its dimensions or appearance. Electropolishing, on the other hand, produces a brighter and smoother surface finish, reducing roughness by up to 50% and providing up to 30 times more corrosion resistance than passivation.

Heat Treatment

We offer several heat treatment options such as hardening, tempering, annealing and normalising for components that require increased surface hardness, temperature resistance, ductility or strength.

Surface Finishing

We provide a range of surface finishing options to improve component form and function, these include:

- Vapour blasting

- Anodising

- Electroplating

- Chemical blacking

- Chromium nitride

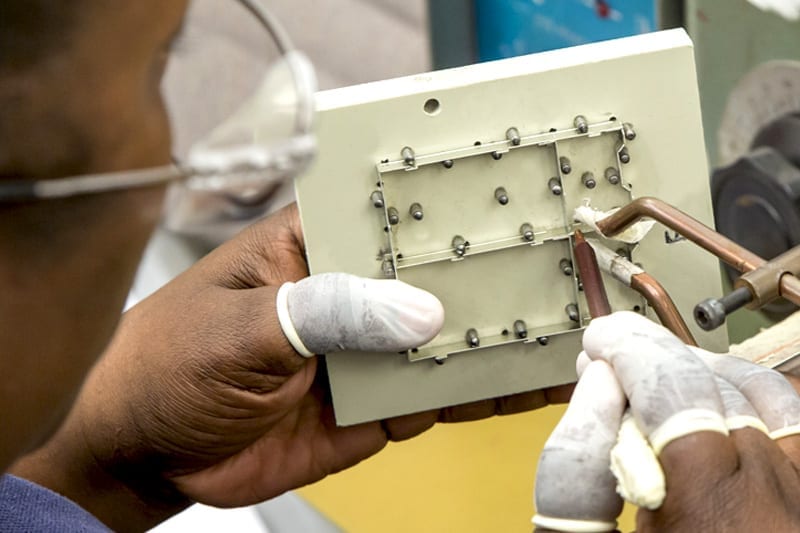

Diffusion Bonding & Brazing

Our diffusion bonding and brazing services cater to the needs of two more components requiring a strong bond. Brazing offers versatility in joining dissimilar metals and complex geometries using a brazing foil, while diffusion bonding creates a homogenous structure that withstands mechanical stresses, vibrations and thermal cycling.

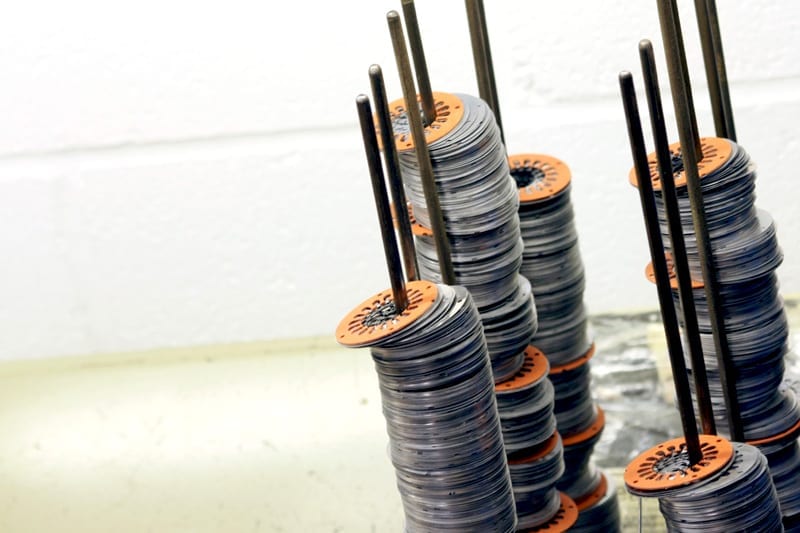

Wire Electro Discharge Machining (WEDM)

Wire electro-discharge machining, also known as spark erosion, is a technique that utilises electric current and fine wire to cut conductive materials with low residual stress. By combining WEDM with etching, we can achieve component profiles cut to tighter tolerances with ±0.005mm accuracy.