Chemical etching Inconel: The Precision Micro advantage

Inconel’s outstanding mechanical properties make it a preferred material in industries facing extreme environments. However, these same properties can present significant machining challenges. This is where Precision Micro excels. As experts in photochemical etching for more than 60 years, we offer a stress-free, precise, and economical solution for manufacturing complex Inconel components across a range of engineering applications.

What Is Inconel and Why Is It So Hard to Machine?

Inconel is a family of nickel-chromium-based superalloys engineered for strength, thermal stability, and corrosion resistance. Common grades include:

- Inconel 600: High strength and corrosion resistance in harsh environments.

- Inconel 625: Excellent corrosion resistance and strength across a wide temperature range.

- Inconel 718: Weldable and strong, suitable for applications up to 650°C.

- Inconel X-750: Resistant to corrosion and high temperatures, ideal for aerospace components.

Challenges Using Traditional Machining

- Work hardening: Inconel rapidly becomes harder when machined, increasing tool wear.

- Thermal resistance: Generates excess heat during conventional processes.

- Risk of distortion: Thin or complex parts are vulnerable to stress and deformation.

Can Inconel Be Chemically Etched?

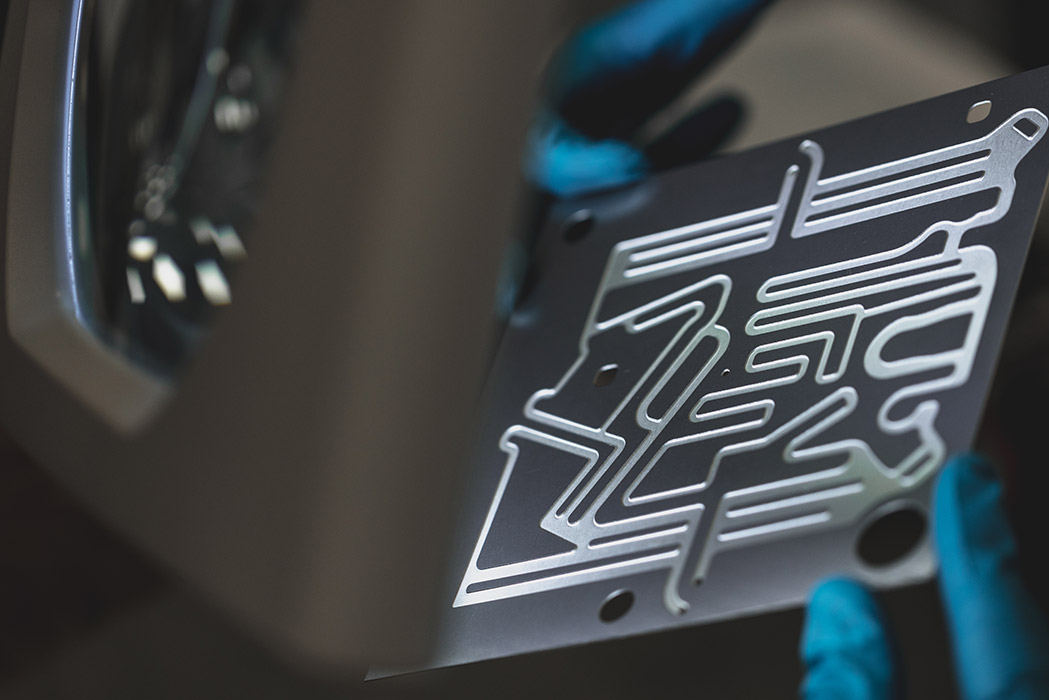

Yes. At Precision Micro, we have developed a specialist chemical etching process for Inconel that delivers consistent, high-quality results — even for the most demanding applications.

Our approach combines in-house-developed etchants, tailored specifically for nickel-based alloys, with tightly controlled process parameters. This allows us to produce complex geometries with clean edge definition, tight tolerances, and no burrs or mechanical stress.

Because chemical etching is a non-contact, ambient-temperature process, it eliminates the risk of distortion — making it especially well-suited to thin-gauge or intricate components.

We process Inconel sheets from 0.013 mm (0.0005″) up to 2.0 mm (0.080″). Combined with digital tooling and short lead times, our process is ideal for high-precision Inconel parts up to 1500 mm x 600 mm — whether for aerospace, energy, or other critical industries.

Typical Applications for Precision-Etched Inconel Components

- Gas turbine engine parts

- Heat shields and liners

- Combustion system components

- Compact heat exchanger plates (e.g. PCHEs)

- Electrolyser and fuel cell components

Why Choose Precision Micro for Etching Inconel?

When it comes to manufacturing precision Inconel components, capability matters. At Precision Micro, we combine deep material knowledge with specialist facilities and a proven track record in delivering complex parts at scale.

What sets us apart is not only our ability to etch nickel-based alloys like Inconel with accuracy and consistency, but also the supporting infrastructure that ensures quality and reliability at every stage.

- Multiple high-capacity etch machines for scalable production

- Controlled cleanroom environment for consistent results

- AS9100 and IATF 16949-certified quality systems

- Access to secondary services such as forming, plating, and diffusion bonding through trusted partners

- Whether you’re developing prototypes or managing volume production, we offer the precision and flexibility your application demands.

Get in touch to discuss your Inconel requirements with our technical team.

Frequently Asked Questions (FAQ)

Can Inconel 625/718 be chemically etched?

Yes, both grades are suitable for chemical etching with the right chemistry and process control.

What tolerances are achievable?

Typical tolerances are ±10% of material thickness, to a minimum of ±0.025 mm, depending on part geometry.

Is it suitable for prototyping?

Absolutely. Our digital tooling approach allows for fast and cost-effective iterations.

What is the maximum thickness that can be etched?

We can etch Inconel up to 2.0 mm thick.

Do you offer any post-processing or secondary services?

Yes. In-house and through our network of partners, we offer additional services such as forming, plating, and bonding where required.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download