How Precision Micro supports Pickering in making relays 25% the size of rivals

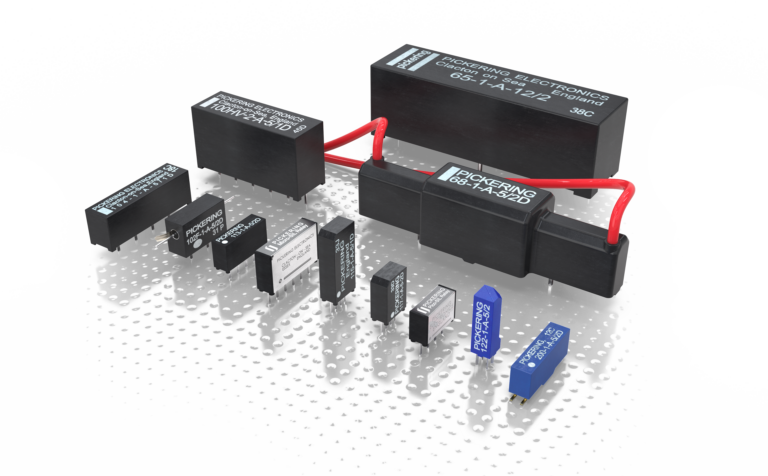

Designing the world’s smallest two-pole reed relay, measuring just 5 mm × 5 mm, pushes the practical limits of miniaturisation. It’s one of Pickering Electronics’ most compact reed relay designs to date and a reminder of a reality in electronics manufacturing, where smaller designs leave far less room for error.

Here’s how, for more than 30 years, Pickering has worked with its chemical etching partner, Precision Micro, to produce precision lead frames and metal components that enable smaller, higher-density designs without sacrificing consistency at scale.

Progress in electronics is often measured in fractions of a millimetre. While individual components may be tiny, the consequences of failure rarely are. That’s why modern electronics manufacturing relies on automation and repeatability, with densely packed systems leaving assembly lines highly sensitive to dimensional variation.

In high-volume production environments, components must also more than meet specification “on paper”. They need to perform consistently through automated handling and assembly, where even minor dimensional differences can disrupt throughput.

At the same time, R&D teams are under pressure to reduce footprints, shorten development cycles and bring new designs to market quickly, while preserving long-term reliability.

For many, this prods regular reassessment of manufacturing routes and suppliers as part of prudent supply-chain resilience, ensuring repeatability and scalability as designs shrink.

Pickering’s challenge

Known for over 50 years of reed relay expertise, Pickering Electronics design and manufacture reed relays for test & measurement, semiconductor automated test equipment (ATE) and other demanding applications.

That’s how the company has built a reputation on miniaturisation and dependable performance in applications where failure is simply not an option. This challenge is one shared by much of the electronics sector but felt more acutely at the high-reliability end of the market.

For instance, reed relays can incorporate precisely formed metal subcomponents into high-value assemblies. However, this raises the stakes because small variations early in the supply chain can compromise performance later in the build process, when rework is expensive or impractical.

Components must also meet extremely tight tolerances too. Not just for performance reasons, but because they feed directly into automated assembly processes where even small deviations can cause disruption across production lines and, by extension, across the wider group.

Overlay this with the need for rapid prototyping, frequent design iteration and product lifecycles that can span decades, the challenge multiplies. So, how do you maintain precision and repeatability across the supply chain while pushing the boundaries of miniaturisation?

Establishing the manufacturing route

Pickering’s relationship with Precision Micro began as a response to these constraints. Chemical etching offers a reliable way to achieve fine, repeatable lead frame geometries while supporting rapid design iteration as relay footprints continued to shrink.

Precision Micro was selected based on its ability to deliver tight tolerances, predictable quality and dependable turnaround, all essential for components used in miniature, high-reliability devices.

And, as Pickering’s portfolio evolved, chemical etching became embedded into both development and production workflows, supporting early prototypes and volume manufacture.

Like many manufacturers operating in high-reliability markets, Pickering periodically reviews alternative processes, such as stamping, as part of robust supply chain management. Yet alternatives can struggle to meet the combined demands of accuracy, repeatability and cost when applied to extremely small, complex geometries.

Why chemical etching?

The process of chemical etching uses controlled chemical machining to form metal components, avoiding the mechanical stresses associated with stamping lead frames. This enables extremely fine detail, tight tolerances and consistent geometry, all critical in miniature electronic assemblies.

That capability matters most during development. New relay designs often involve multiple iterations before the correct configuration is achieved, which is usually driven by customer-specific requirements or the need to reduce printed circuit board (PCB) footprint.

Chemical etching supports this need by enabling fast turnaround and low-cost tooling, allowing engineers to refine designs without committing to expensive press tools too early.

As designs move from development into production, the emphasis then moves from flexibility to repeatability. Precision Micro’s manufacturing relies on automated inspection, where dimensional accuracy and visual uniformity is essential.

At this stage, even small variations can disrupt throughput. Chemical etching provides the process stability required to scale reliably from prototype to volume manufacture, otherwise, the consequences of a supplier failing to meet tolerance requirements are immediate and far-reaching.

Pickering Electronics operates as part of a wider group supplying relays, test and measurement equipment and interconnect solutions. This means that disruption in one area could quickly affect others.

Pushing the limits of miniaturisation

This capability of chemical etching is best illustrated by one of Pickering’s latest product launches, the aforementioned ultra-miniature two-pole reed relay measuring just 5 mm × 5 mm and 15.5 mm in height.

Integrating multiple etched lead frames into such a compact assembly took around two years of development, resulting in what’s described as the world’s smallest relay of its type.

Reaching this level of miniaturisation was not a single step, but the result of a manufacturing approach that has evolved over time. Like any manufacturing partnership, especially one that goes beyond 30 years, processes have adapted alongside changes in design requirements and production methods.

For example, challenges came with the expansion of Pickering’s Czech manufacturing facility and the transition to higher-volume production outside of the UK. The move was strategically necessary to scale production and for better links within mainland Europe, but introduced short-term challenges around forecasting, scheduling and ordering behaviour as new teams and systems bedded in.

Precision Micro supported the transition by working through fluctuating demand patterns and capacity constraints, particularly around specialist processes such as plating.

“Chemical etching allows us to iterate quickly without locking ourselves into expensive tooling, like stamping, too early,” explained Julie Benson, operations manager at Pickering Electronics. “That flexibility is often what keeps development moving, but it’s not only cost, nor about tolerances in isolation either. It’s about working together when requirements evolve or when something unexpected needs solving.”

“We’ve been working with Pickering for over 30 years, and what’s kept the partnership strong is a shared commitment to flexible problem-solving and precision,” said Rachael O’Connor, sales office manager at Precision Micro. “Over decades, we’ve learned that it’s about how it affects every stage of production, as well as what’s on the drawing.”

The partnership today is supporting Pickering’s most advanced developments. New product launches, such as the 125 series — designed to save printed circuit board (PCB) space by building vertically — and the high-voltage 600 series, show the range of challenges.

In an industry where progress is measured in fractions of a millimetre, trust is built in the same way. Pickering Electronics’ collaboration with Precision Micro shows how tight tolerances and consistency support the finest details of miniaturisation, through a partnership spanning more than 30 years.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download