Filters, Screens & Sieves

Low-cost tooling and unlimited complexity for a range of filtration applications.

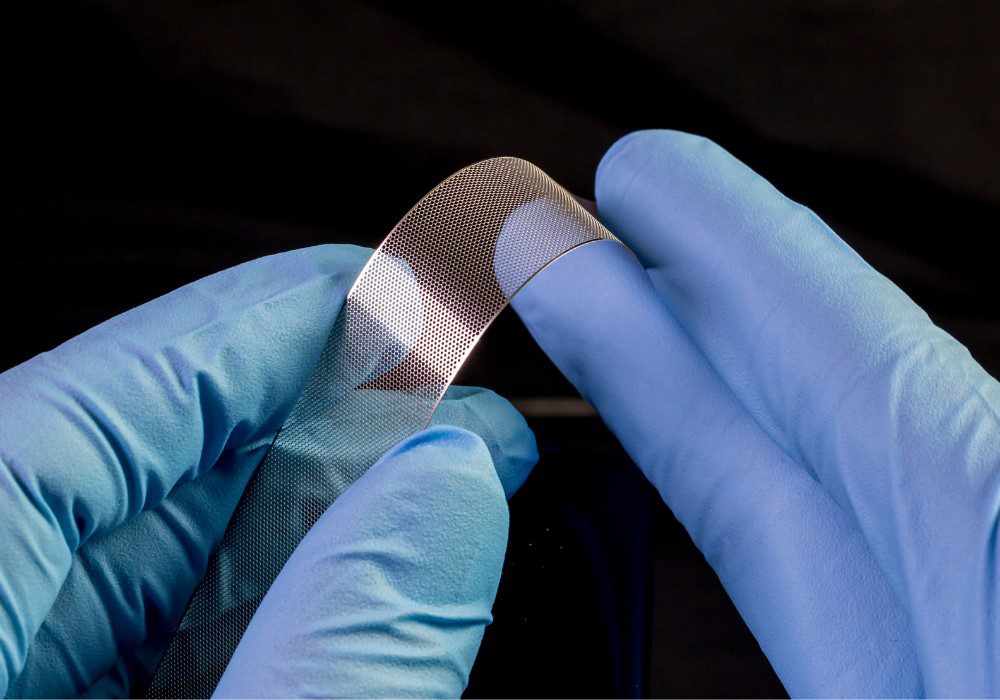

Request Pricing Application NotePrecision Micro offers an advanced chemical etching service for manufacturing filters, sieves and screens, outperforming traditional perforating techniques with greater speed, flexibility and cost-effectiveness.

Traditional sheet metal perforation

Filters, screens and sieves play a crucial role within numerous engineering applications by separating solids from liquids or particles of different sizes. Stamping is the most widely used manufacturing process for perforating metal sheets due to its cost efficiency in large-scale production runs. However, it does have limitations, such as its limited flexibility, restricted customisation options for complex design, expensive tooling, constrained material choice and the potential for burrs and stresses.

Sheet metal perforation using photochemical etching

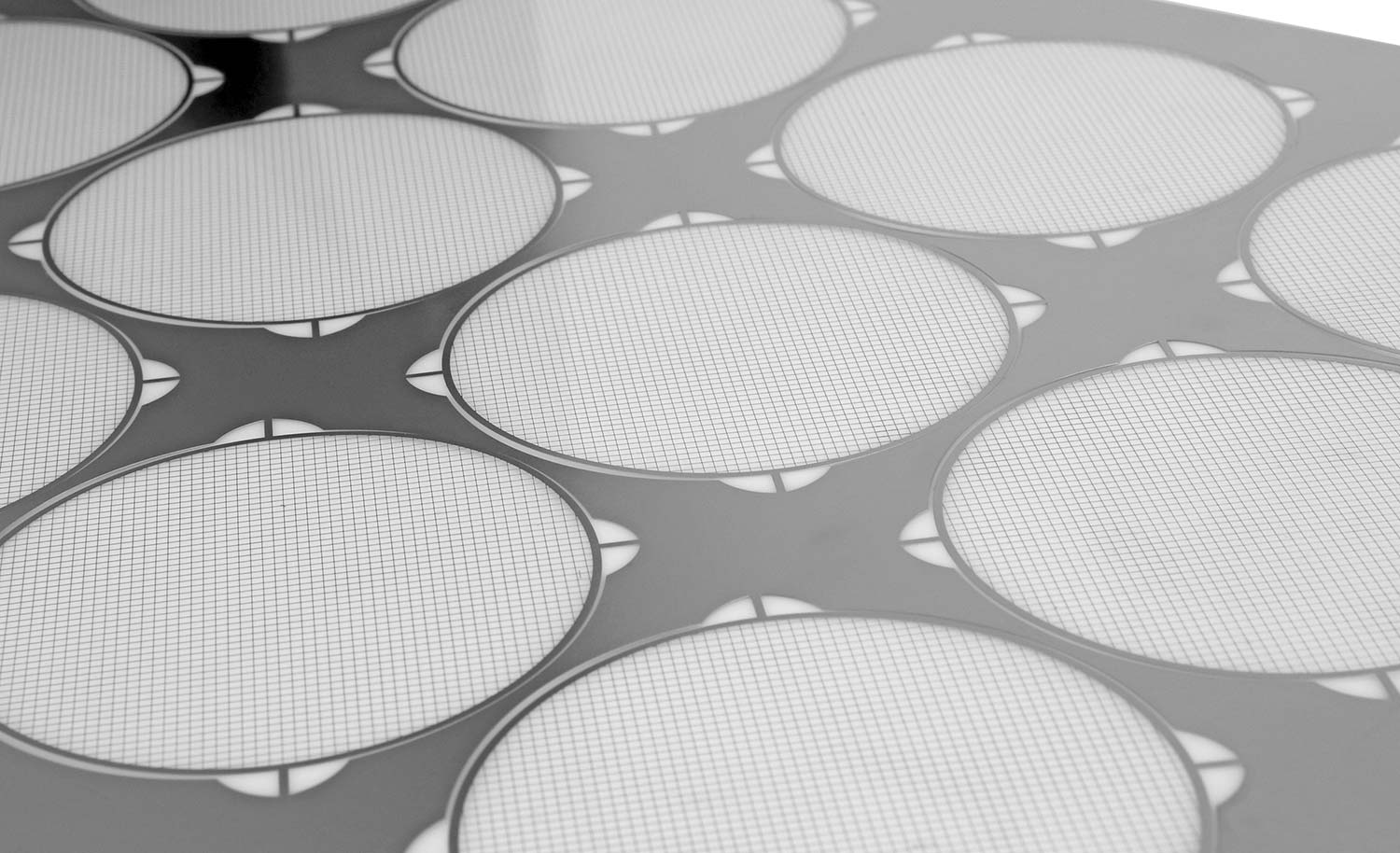

Photochemical etching is a subtractive manufacturing process that selectively removes material from metal sheets through a chemical reaction. By using cost-effective digital tooling and simultaneously machining all mesh openings, it enables the production of components with limitless complexities, structures and geometries. This approach significantly reduces costs and lead times while also facilitating easy design modifications.

Uncompromising precision

Etched filters, sieves and screens can undergo precise machining to achieve openings as small as 0.1mm, with accuracy to ±0.020mm. This precision applies to material thicknesses ranging from 0.01mm to 2.5mm. Our chemical etching service guarantees the production of metal meshes that are entirely free from burrs and stress.

Benefits

Unlimited complexity at a fixed cost

Openings to 0.1mm

100% burr and stress-free

Prototype to high volume production

Material versatility

Chemical etching exhibits remarkable versatility, excelling not only in producing scalable volumes but also in its capability to work with virtually any type of metal. Unlike stamping, this method remains unaffected by materials with hard, soft or brittle properties, making it a superior solution for overcoming production challenges associated with such material factors.

Meshes, Filters and Sieves Application Note

Learn more about the benefits of chemical etching components for diverse range of filtration applications.

Download