Small parts. Big impact. Etching for a greener future.

In a world driven by the demand for cleaner, smarter and more efficient technologies, energy has become the common thread pulling together innovation across multiple industries. Whether on the ground in electric vehicles, deep in the hydrogen supply chain, soaring through the skies in next-gen aircraft or even orbiting the Earth aboard space missions, energy systems are evolving. At the heart of many of these breakthroughs is chemical etching, explains Ben Kitson, head of business development at Precision Micro.

Chemical etching might not grab headlines, but it’s quietly powering some of the most advanced technologies around — from satellites to hydrogen fuel systems. By using controlled chemical reactions to remove metal with pinpoint precision, it creates complex, stress-free components that traditional methods like stamping or laser cutting can’t match.

However, as demand for high-complexity components continues to rise, etching is stepping into the spotlight. This shift is most visible in energy systems across multiple sectors.

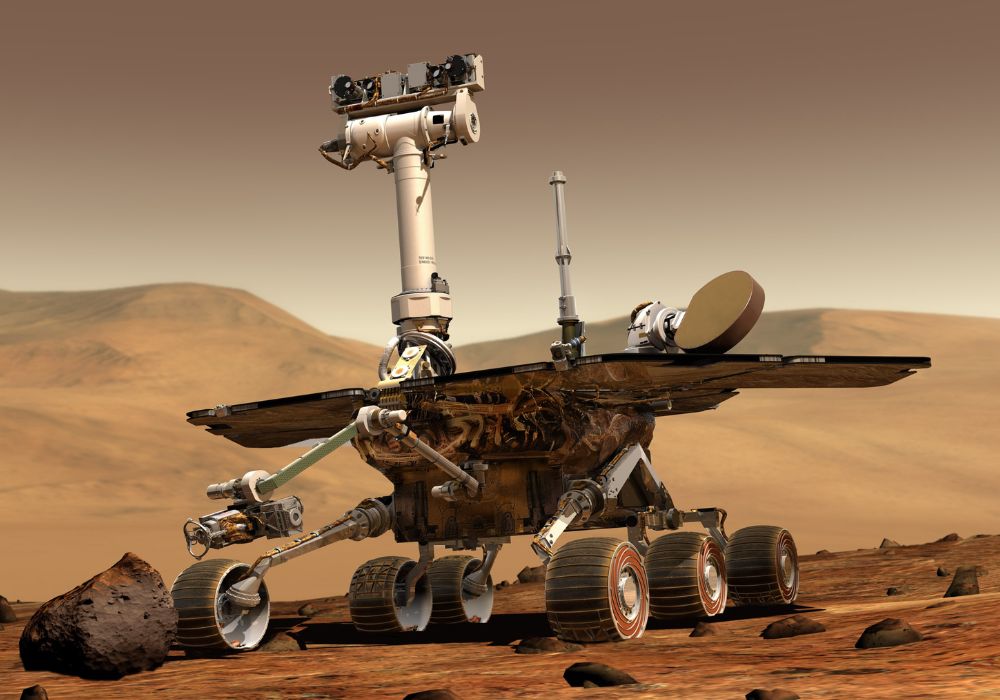

Space

Recent surveys suggest a boom in space missions from both public agencies and private operators. This has created a demand for small but vital components like thin, etched nickel interconnects used in lithium-ion batteries for satellites and exploration vehicles that will study exoplanets.

Although the components may sound simple, their applications are anything but. They are used in systems built to operate in the extreme conditions of deep space, as seen in projects like the Mars Rover. That’s a remote-controlled robotic vehicle developed to explore the Martian surface and the upcoming ExoMars mission in 2028, which aims to search for signs of past life on Mars.

This is engineering at its toughest. It’s not about producing large volumes of simple components, but about processing specialist materials burr and stress-free quickly, flexibly and with precision.

Chemical etching is ideal for this because it keeps tooling costs low and allows for rapid design changes, making it perfectly suited to high-precision work where there’s no room for error.

Aerospace

Aerospace is made up of a blend of legacy and future-facing technology. Today’s innovation is not just on electric or hydrogen-powered aircraft, but also on making current combustion engines cleaner and more efficient.

Thermal management is a key area of focus here. Compact aluminium heat exchangers rely on etched aluminium flow plates used in aircraft engines to manage cooling airflow with higher efficiency. These plates, with their intricate channel designs, are evolving into fuel cell bipolar plates in hydrogen systems.

They’re not speculative, they’ve been in the market for over a decade, but evolving manufacturing capabilities are helping to revisit and optimise them for the next generation.

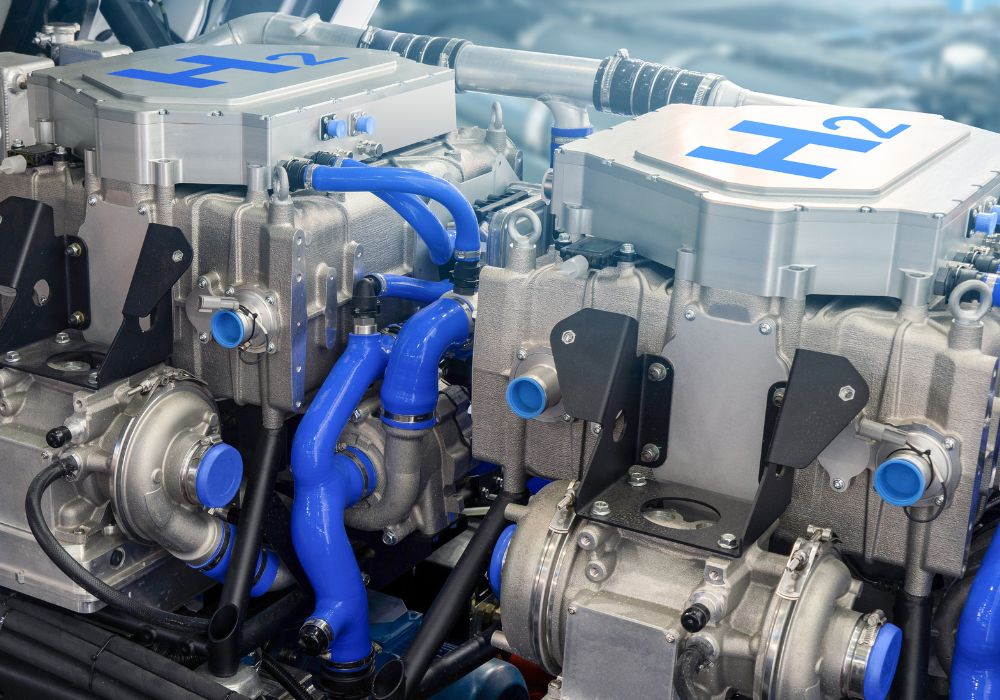

Hydrogen and electric

The conversation continues with on-land vehicles too. Electric vehicles and hydrogen fuel systems are often seen as competitors, but the reality is more complementary, particularly when you zoom out and look at where each is most viable.

Wondering why this might be the case? Well, the European International Council on Clean Transportation (ICCT) highlights that hydrogen fuel cell vehicles could soon outperform EVs in emissions reduction, provided they run on renewable hydrogen.

The study suggests FCEVs could emit 79 per cent fewer emissions than internal combustion engine vehicles over their lifetime, which is slightly better than battery EVs using renewable electricity.

That said, this doesn’t mean hydrogen will replace battery-electric vehicles across the board. It’s likely we’ll see a combination of the two. EVs dominate the passenger car market, while hydrogen is gaining real traction in heavy-duty transport, long-haul logistics and commercial fleets.

Behind both are systems built around connectivity — not of data, but of energy. Battery packs, fuel cells and heat exchangers all rely on etched components such as busbars, bipolar plates and printed circuit heat exchangers to enable power delivery and thermal management.

In hydrogen, this might involve supplying plates for electrolysers that generate hydrogen, or the heat exchanger flow plates that help compress and dispense it into a truck. The same principles apply inside the vehicle itself, whether that’s a hydrogen-powered lorry or a new-generation aircraft using fuel cell systems.

What’s interesting is how naturally this transition follows on from existing capabilities. Etching has long played a role in combustion-era automotive manufacturing, from injector components to under-the-hood systems. Now, the same process is enabling fuel cells, EV battery connections and the entire hydrogen ecosystem.

And unlike combustion, where the goal was incremental efficiency, the stakes here are existential. Hydrogen isn’t a side story, it’s a key piece of the energy transition puzzle.

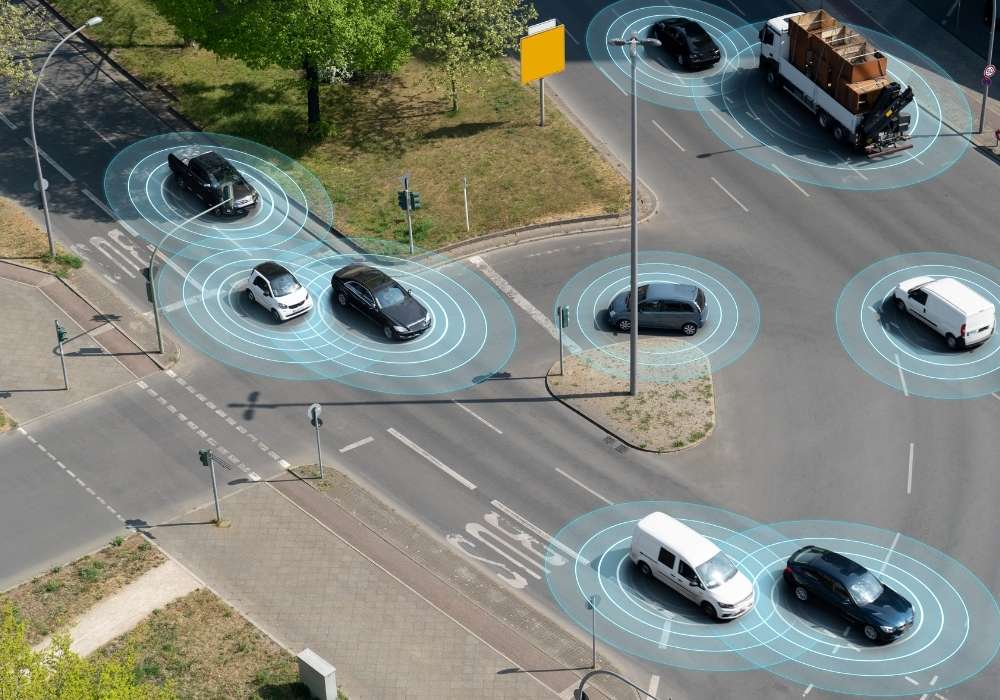

Autonomous vehicles

That crossover is part of a broader trend in autonomous vehicles. For example, in the US, etched copper bus bars are being used in the battery packs of autonomous robo-taxis. As for the UK, a fuller rollout of self-driving taxis will come after the Automated Vehicles Act fully takes effect in late 2027.

These packs sit under the passenger seat, with rows of AA-sized cells connected by precisely engineered bus bars featuring break points that isolate failures and prevent full-pack shutdown.

It’s a classic pre-series development setup, with thousands of parts produced in moderate volumes, all within tight turnaround windows and changing specs. Chemical etching shines here, offering speed, precision and flexibility. While these vehicles may move to high-volume stamping processes later, etching helps in the early stages where design isn’t yet locked.

And there’s a wider trend to acknowledge, the technology used in an autonomous vehicle’s battery is structurally similar to that used in satellites. The context shifts, but the engineering need remains constant to connect, conduct and control power. Yet, unlike in space, the development volumes are still in the thousands before higher production methods take over.

A cross-sector reality

The underlying message here is that there’s sectorial convergence. Energy systems in space, air, land and sea are being determined by the same fundamental forces. That’s demand for cleaner power, the need for agility in design and the pressure to deliver quickly.

Chemical etching can support rapid prototyping, deliver precision without introducing stress and work across a wide range of materials, making it a natural fit for the pace and complexity of modern engineering.

From pure nickel in satellites to copper in EVs and specialised alloys in space-grade systems, the process adapts across applications while maintaining consistency in outcome.

Energy is the thread connecting progress across multiple applications, whether that’s orbiting satellites or on-road innovation. After all, the future isn’t just on the horizon — in many cases, it’s already in production.

For more information on chemical etching, download Precision Micro’s latest whitepaper here. Alternatively, contact the team at +44 (0) 121 380 0100.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download