Aerospace, Defence & Space

AS 9100-certified aerospace components.

Contact UsTrusted to deliver by industry leading names

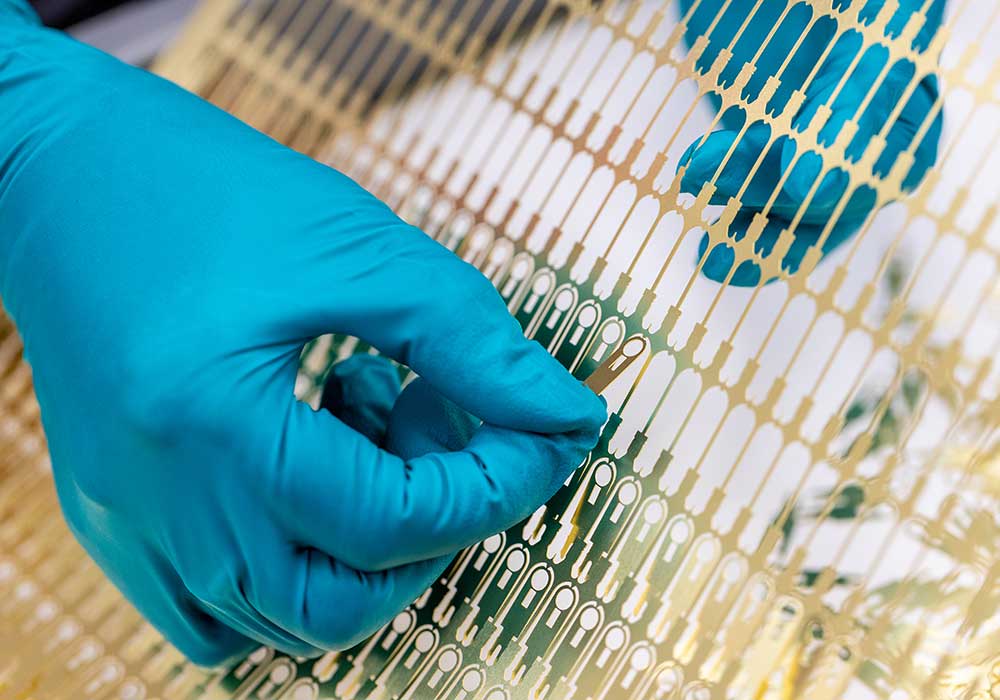

Precision Micro, an AS 9100 accredited component manufacturer, stands as a trusted supplier globally recognised for delivering safe, reliable and high precision components to the aerospace, defence and space industries.

MATERIAL VERSATILITY

Our chemical etching service offers unparalleled versatility, accommodating a wide range of aerospace-grade metals. From lightweight, corrosion-resistant aluminium to high tensile strength stainless steels, we excel at working with materials that are often challenging to machine using conventional sheet metalworking techniques.

Materials suitable for chemical etching

PERFORMANCE & RELIABILITY

In the aviation industry, performance and reliability are paramount. Our photo etching process ensures 100% stress, burr and distortion-free components. With precision accuracy achievable to within ±0.020mm, you can trust that every part will maintain its material integrity during machining.

Benefits

AS9100-accredited

100% burr and stress-free components

Scalable supply

Precision accuracy

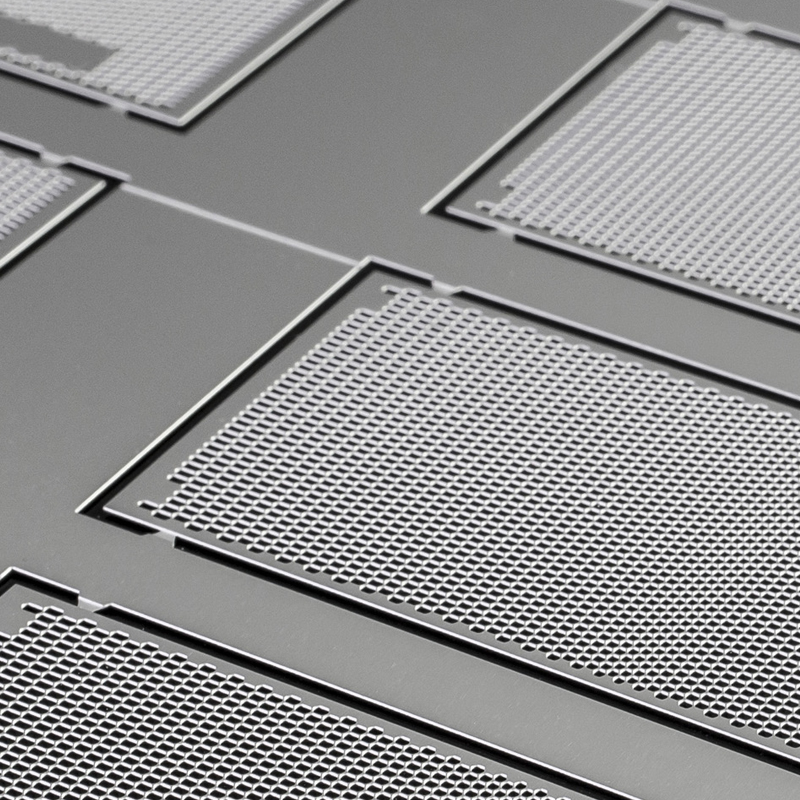

AEROSPACE, DEFENCE & SPACE COMPONENTS

Chemical etching offers infinite versatility and scalability, making it suitable for a wide range of components. From metal shims, springs, interconnects, intake grilles, filters, and EMI shielding to specialist designs, components can be chemically etched and combined with other post-process services such as forming, bonding or plating, streamlining your supply chain.

Custom Metal Shims

Flat Springs

PCB Shielding Cans

Filters, Screens & Sieves

ELECTRIFICATION & MINITURISATION

As a world leader in the industry, Precision Micro specialises in producing heating elements for electro-thermal ice protection systems. We have also partnered in the development of miniaturised electric motor laminations for pioneering pocket-sized surveillance UAVs.

Today, we continue to co-develop parts that enable the technologies of the future, including compact heat exchangers, bipolar plates for hydrogen and electric flight, and electronics components for space travel, satellite communication and enhanced airport security biometrics.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download