Complex component prototyping in as little as 24 hours

Photochemical etching offers the chance to prototype from the widest range of materials, including those deemed difficult to work with, with little to no set-up costs and delivery in as little as 24 hours.

However, it’s almost the sector’s best-kept secret with most design engineers defaulting to “traditional” methods. But for many industries such as automotive, aerospace, electronics and healthcare, etching could be the key to delivering increased time to market demands.

Complexity made simple

Conventional machining, laser cutting and stamping can face various issues when machining certain metals, resulting in additional operations that can increase lead times.

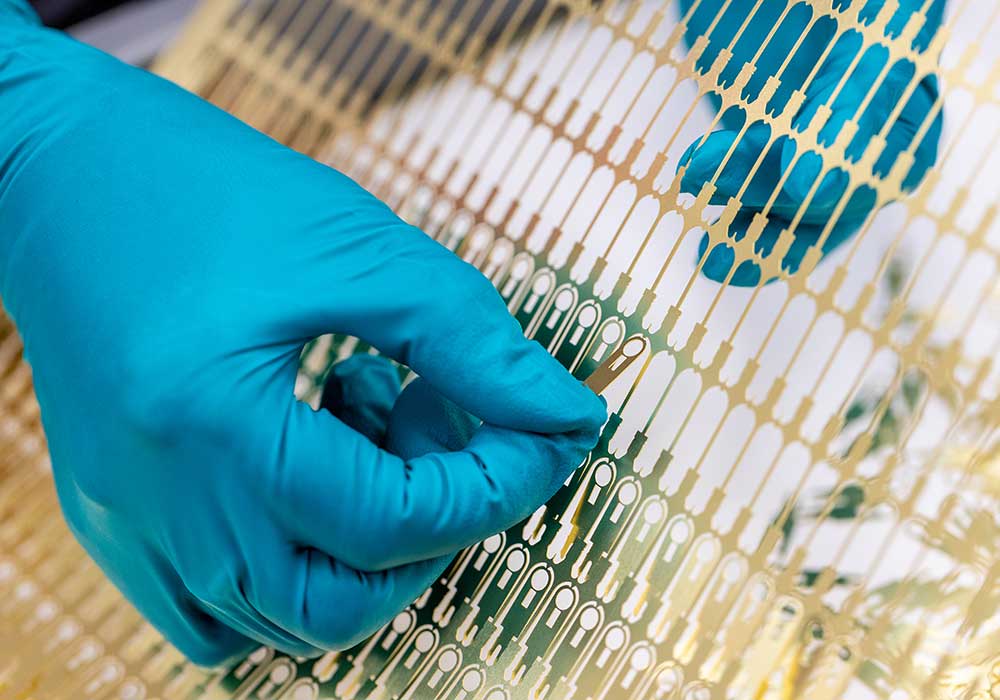

Photochemical etching, which uses chemical etchants to create complex and highly accurate precision components, by comparison, presents a more economical and efficient way to produce custom parts with complex designs and strict tolerances.

This is possible by UV printing the part design through a phototool stencil onto sheet metal laminated with a light-sensitive polymer. The design is then selectively developed then etched, offering a less intrusive and more delicate process for creating quality, intricate components.

The value of photochemical etching is truly found through the inexpensive and easily reworked phototools that ensure high accuracy and repeatability in production, perfect for providing OEMs with the critical components they need in short lead times for a great price.

Top-quality without intervention

Precision etched components are vital elements of many applications and even the slightest blemish can create significant disparities in the quality of the final product. Traditional processing methods can cause those issues.

Thermal and cutting edge stresses are familiar factors that affect the quality of the components produced. Thermal stress results from heat generated during the metalworking process while cutting edge stress is a result of stamping, which can have a detrimental effect on the flatness of a blank.

Photochemical etching eliminates potential stress as there’s no heat or physical impact. Similarly, with no impact force or harsh cutting, there are no burred edges. Only by using photochemical etching can you eliminate the uncertainty and guarantee quality and repeatability across all your components.

Reducing time in R&D

Photochemical etching can simplify the development (and production) process as it eliminates stress and burring, allowing for products to be delivered to an exceptional standard in hours – rather than weeks or months. It also reduces tooling time and costs, with no expensive hard tooling required.

While chemical etching provides simplicity, the process also allows even the most complex of parts to be created, opening more design avenues for you and your clients.

It’s clear that photochemical etching should be considered as a solution for cutting precision metal components, with reduced lead times, fewer costs and the ability to precisely cut even the most difficult metals in larger quantities.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download