Electronics

Miniaturisation, speed and economy for the electronics industry.

Contact UsTRUSTED TO DELIVER BY INDUSTRY LEADING NAMES

With over 60 years of experience, we have a deep understanding of the specific requirements and challenges faced by the electronics sector, consistently delivering innovative component solutions that have set new benchmarks in the industry.

A smarter approach

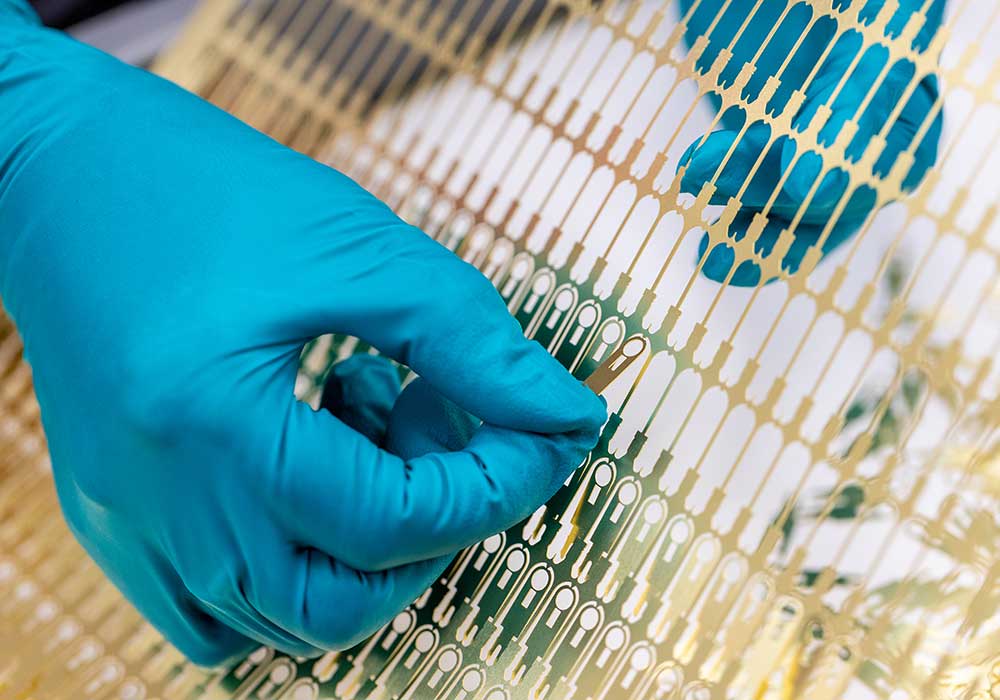

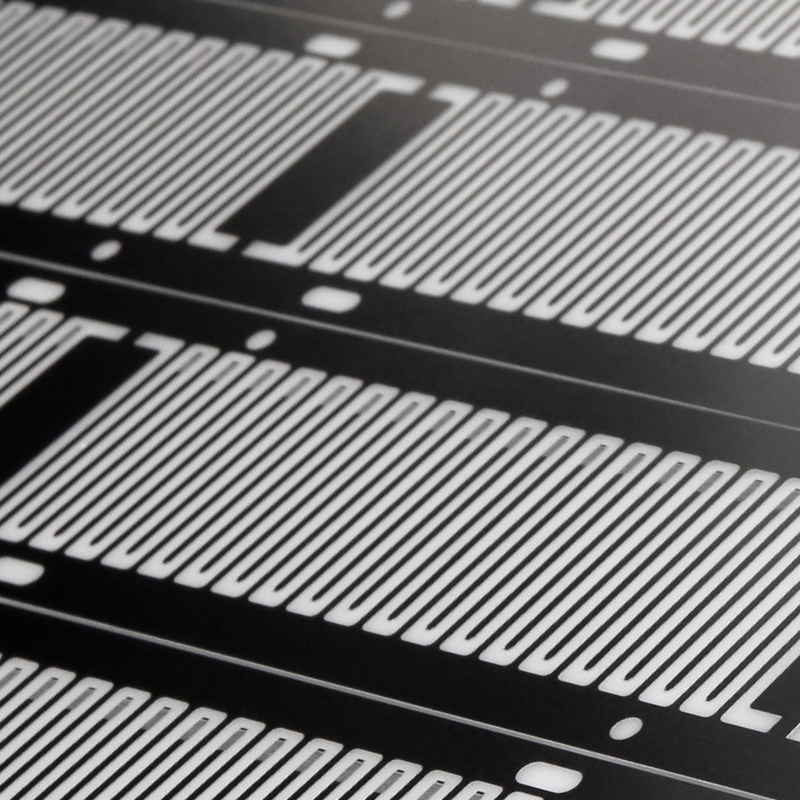

With its roots in the printed circuit board industry, our chemical etching service offers a smarter way to manufacture intricate parts with fine detail.

Unlike conventional machining processes that require expensive and time-consuming hard-tooling, our digital tooling-based approach allows electronics designers to prioritise functionality optimisation, minimise lead times and adopt a low-risk, cost-effective product development strategy. This flexibility enables easy modifications that help meet fast-paced time-to-market requirements.

Learn more about chemical etching

Meeting the demand for miniaturisation

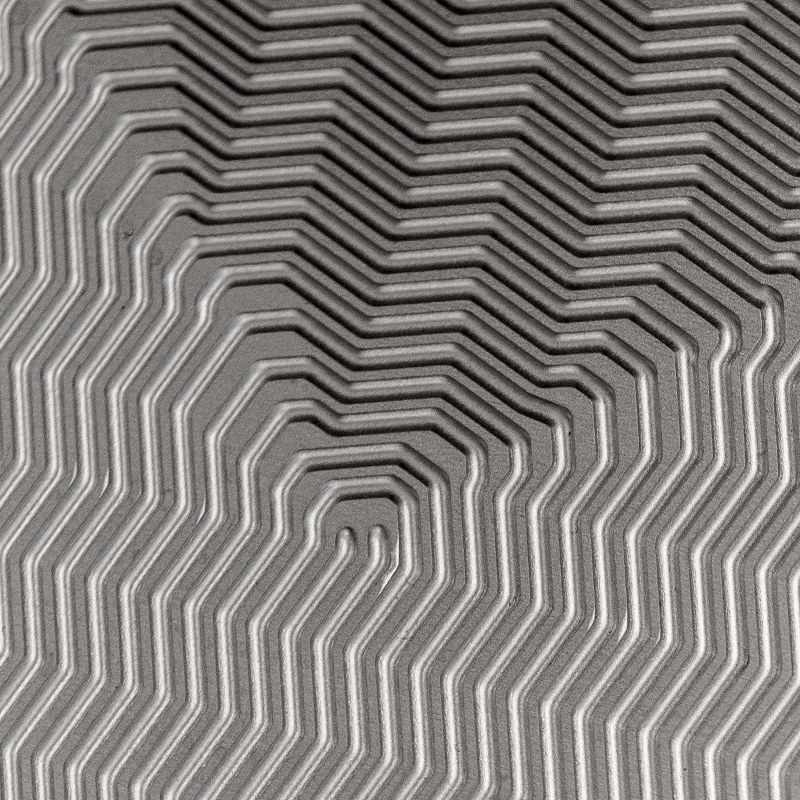

As the electronics industry continues to move towards smaller and more intricate components, there is a growing demand for complex designs, tight tolerances and precise accuracy. Chemical etching provides an ideal solution to meet these requirements, enabling the production of parts with thicknesses as low as 0.010mm and achieving accuracy to within ±0.020mm.

Benefits

Fast, flexible supply

100% burr and stress-free components

Precision accuracy

Low cost tooling

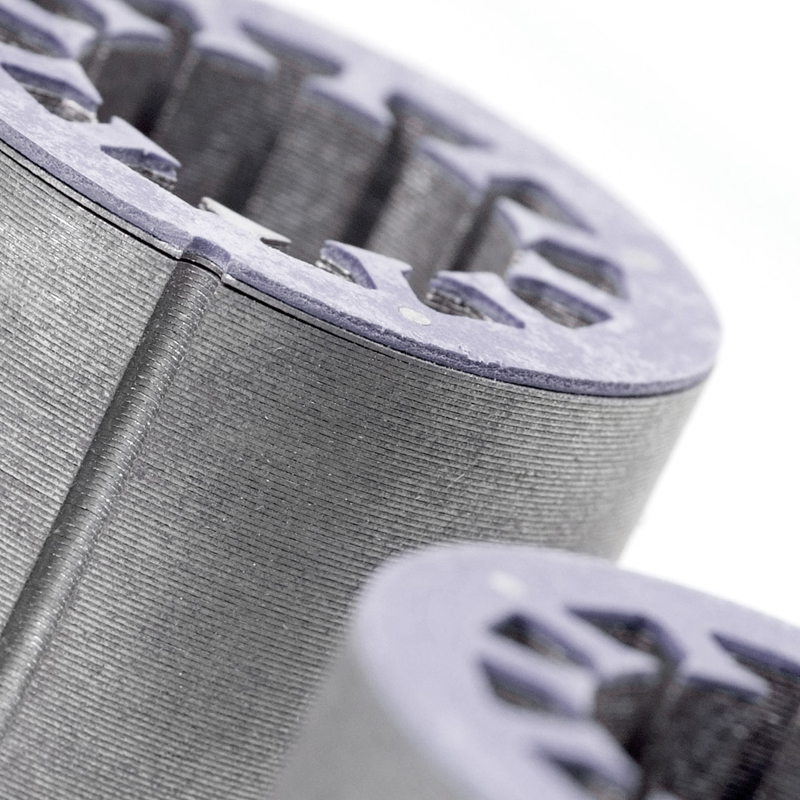

Electronics components

We supply specialist components to the world’s leading electronic companies, from lead frames to PCB shielding cans. Additionally, we offer post-processing services that seamlessly integrate with chemical etching including forming and finishing, heat treatment, bonding, brazing and more.

Electric Motor Laminations

Custom Metal Shims

PCB Shielding Cans

Printed Circuit Heat Exchangers

Lead Frames

Electrical Connectors

Material versatility

The chemical etching process offers compatibility with a wide range of metal types, setting it apart from traditional methods that often face challenges with hard, soft or brittle metals. By dissolving materials on a molecular level, this process yields smooth and precise electronic components, allowing for a high-quality aesthetic finish that is free from burrs and stress.

Download Accreditations

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download