Photo etching FAQs

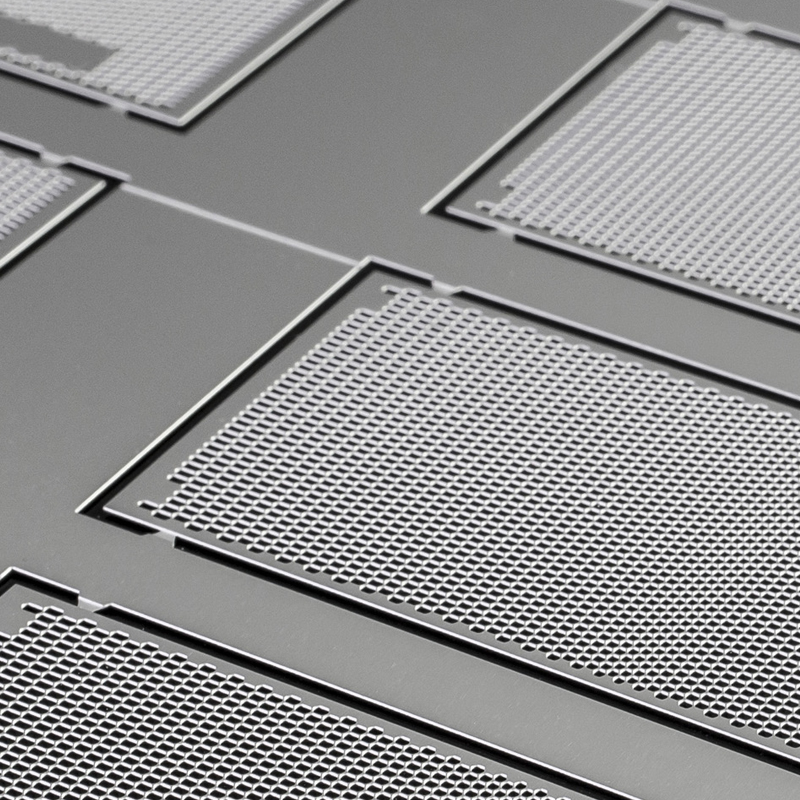

Photo etching is compatible with sheet metals ranging from 0.010 mm to 2.5 mm in thickness and up to 600 mm x 1500 mm in size. However, note that thicker parts may require longer etching times, making metals above 2.5 mm often uneconomical for processing.

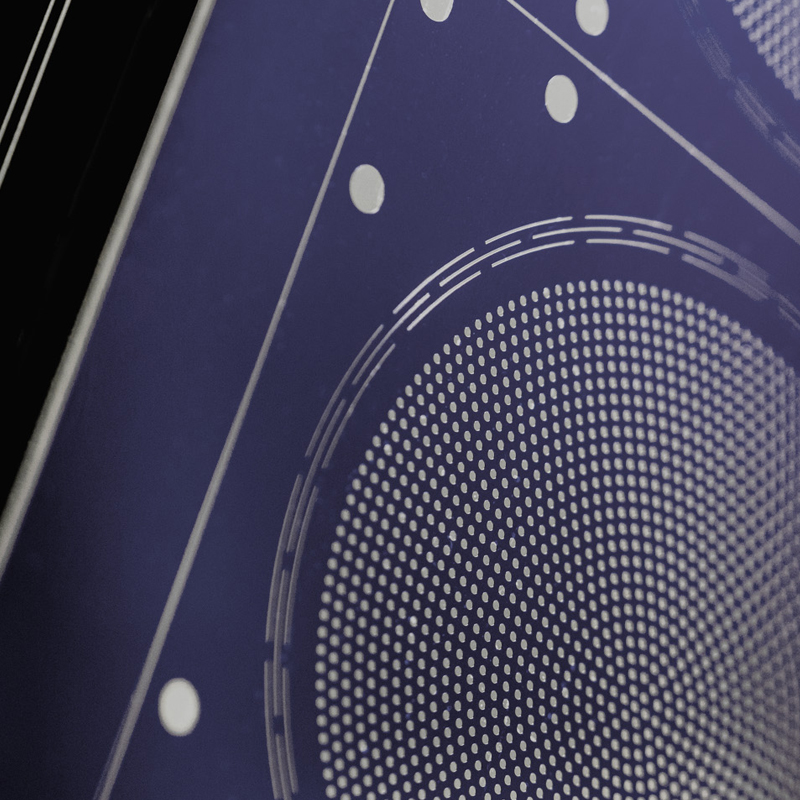

Photo etching offers exceptional accuracy, with standard minimum etching tolerances at ±10% of the metal thickness, down to a minimum of ±0.020 mm. For even greater precision, we encourage customers to collaborate with Precision Micro during the design phase, allowing us to tailor the process to their requirements.

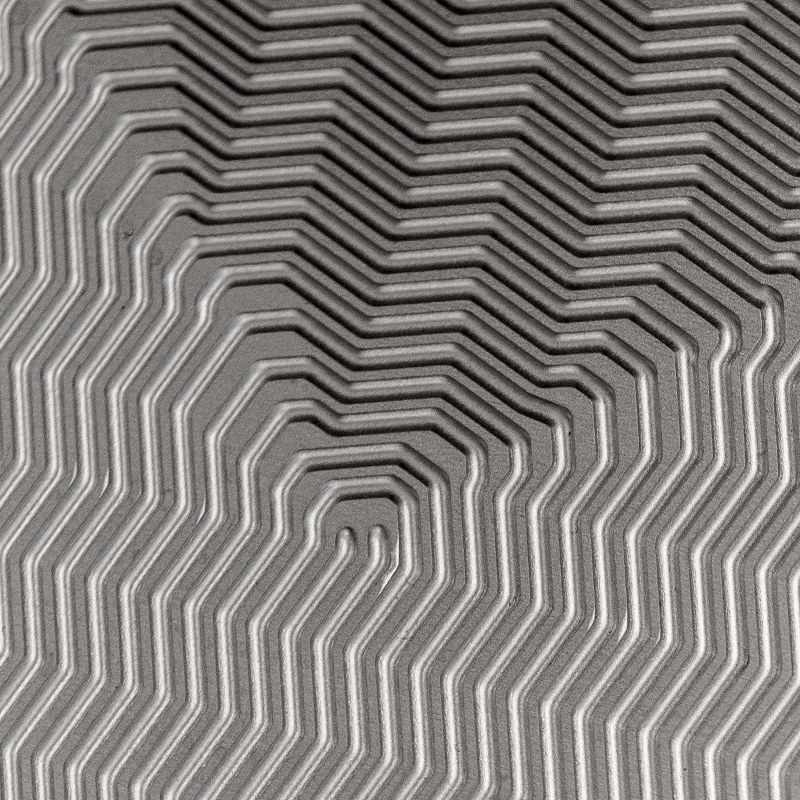

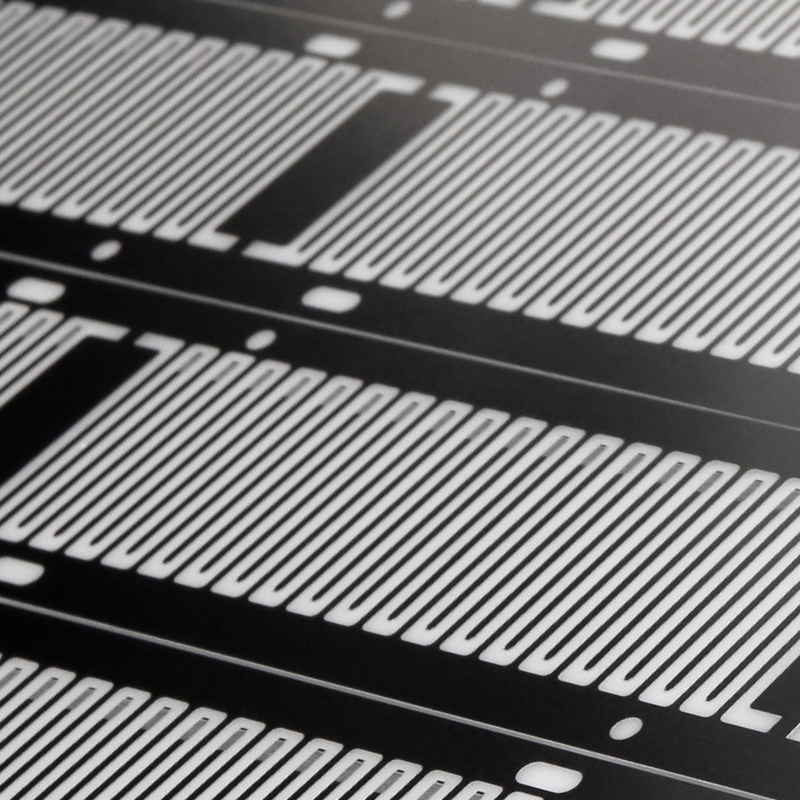

The minimum standard etched opening achievable is 0.1 mm, while for depth-etched features like microfluidic channels, it is 0.020 mm. With further development, even finer features can be attained through the etching process.

With the cost-effective digital tooling involved, photo etching provides the flexibility to produce components without minimum or maximum quantity limitations.

Cost considerations in photo etching are influenced by material thickness and component size. The price is based on the sheet, allowing for lower unit prices when maximising the number of parts per sheet. However, thicker sheets may require more etching time, affecting the overall component cost.

Photo etching lead times are measured in days, not weeks or months, setting it apart from traditional metal machining methods. For standard components without additional post-processing, delivery can often be achieved in two working weeks, while urgent demands can be met even quicker, depending on production capacity.