Automotive

TRUSTED TO DELIVER BY INDUSTRY LEADING NAMES

We take pride in being one of the few photochemical etching companies globally accredited with IATF 16949, demonstrating our commitment to producing the precise and intricate components demanded by the automotive industry.

FROM PROTOTYPE TO TRUE HIGH-VOLUME PRODUCTION

For over 60 years, our innovative chemical etching process has distinguished us from traditional machining and the broader etching industry. Operating from state-of-the-art facilities, we offer the flexibility to seamlessly transition from prototype quantities to true high-volume production without compromising on precision, quality and accuracy.

PRECISION, WITHOUT COMPRIMISE

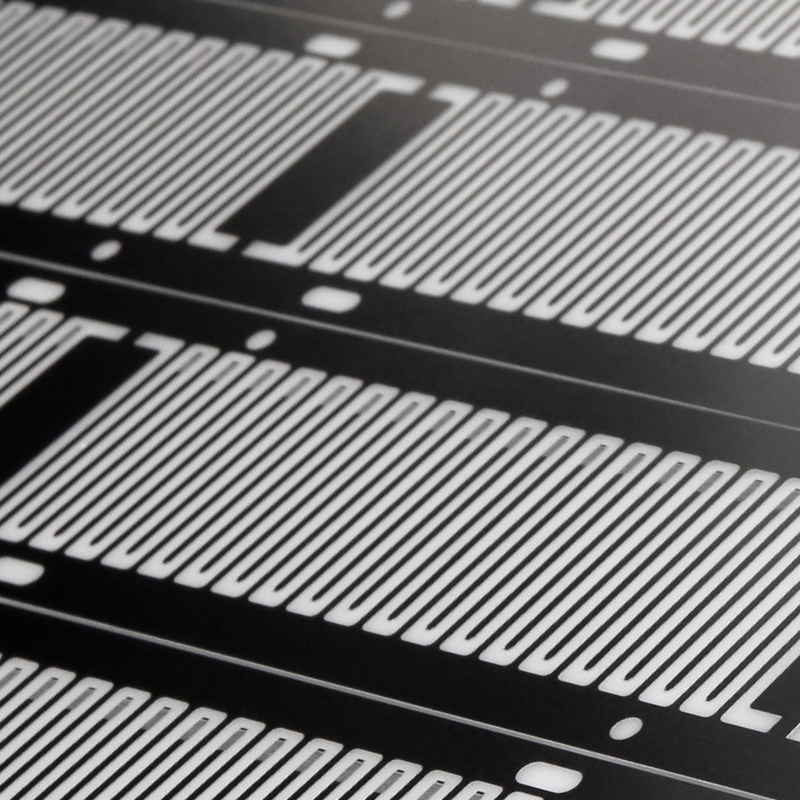

Complex and intricate parts play a vital role in the automotive industry, ensuring optimal functionality, performance, safety, differentiation, innovation and technological advancement. Combining chemical etching with low-cost digital tooling, we have the capability to selectively dissolve precise areas of the chosen metal, enabling precision to within ±0.020mm, all at a fixed cost. This non-contact and non-thermal process eliminates the potential for burrs and stresses, further enhancing component quality.

Benefits

IATF-16949 accredited

Fast, low-cost prototyping

True high-volume production

Wide range of materials

AUTOMOTIVE COMPONENTS

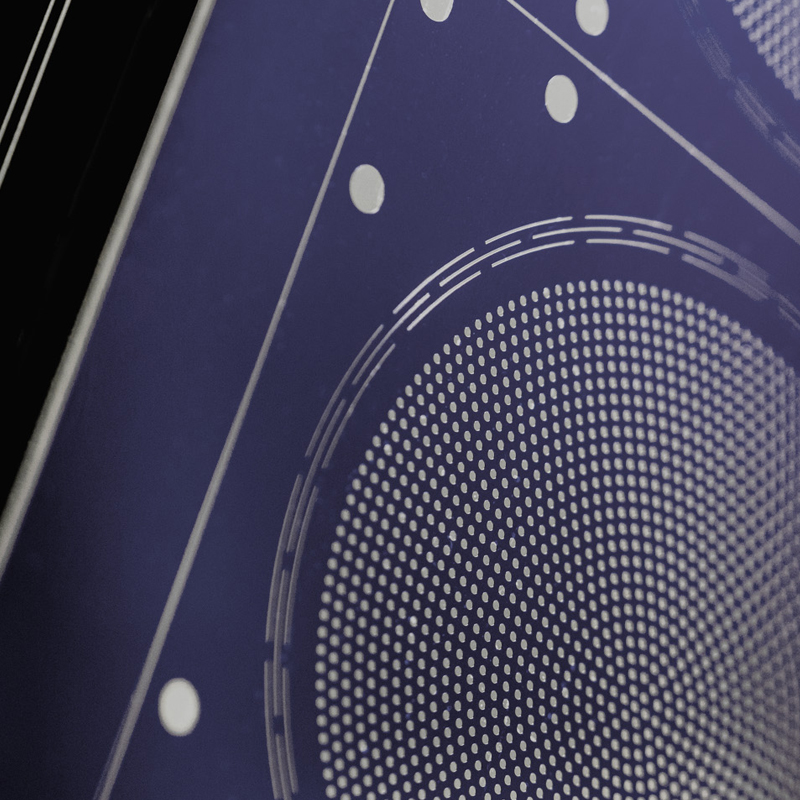

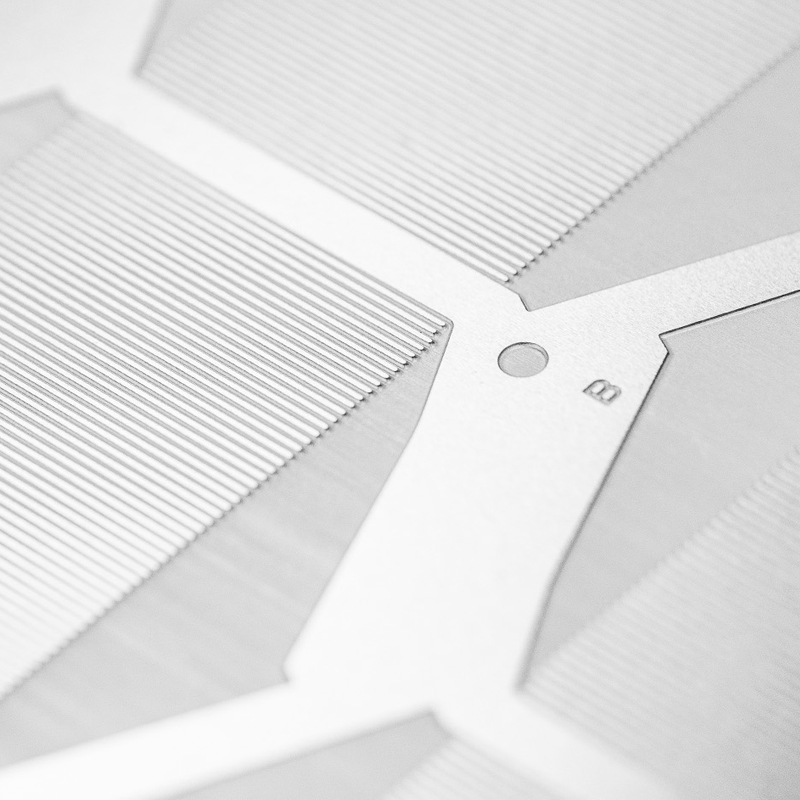

Our fast and adaptable photochemical etching service is ideal for manufacturing a wide range of automotive parts. We produce components such as ABS and GDI flexures, bipolar fuel cell plates, shims, gaskets, filters and luxury speaker grilles for leading automotive brands. These can all be seamlessly integrated with other post-processing services like forming, bonding or plating to optimise your supply chain.

Speaker Grilles

Custom Metal Shims

Bipolar Plates

PCB Shielding Cans

Flat Springs

Electrical Connectors

100% QUALITY ASSURED

At our industry-leading Quality Centre of Excellence, equipped with the latest optical CMM equipment, our highly skilled team ensures that every part is delivered right first time, every time. With quality levels approaching Six Sigma standard, we guarantee unmatched levels of repeatability within the chemical etching industry.

Download Accreditations

Automotive brochure

Learn how Precision Micro is delivering on quality, cost and repeatability for the automotive industry.

Download brochure