Chemical etching: At the forefront of next-gen automotive power

The automotive industry is one of innovation. Though the first electric car was developed in the late 19th century, its move towards mass production some 100 years later has revolutionised the future of road travel.

Today, many consumers are looking to adopt renewable and electric powered vehicles as they look to reduce their carbon footprint, and manufacturers aim to meet emission legislation.

The evolution of hydrogen technology

As the industry changes at pace to meet these demands, Precision Micro is primed to support innovation with its pioneering photochemical etching service, not only with the ramp up of battery technology – Precision Micro specialises in etching the conductive busbars used in battery power distribution – but also with next-gen power including the development of hydrogen fuel cells.

Bipolar fuel cell plates manufacture

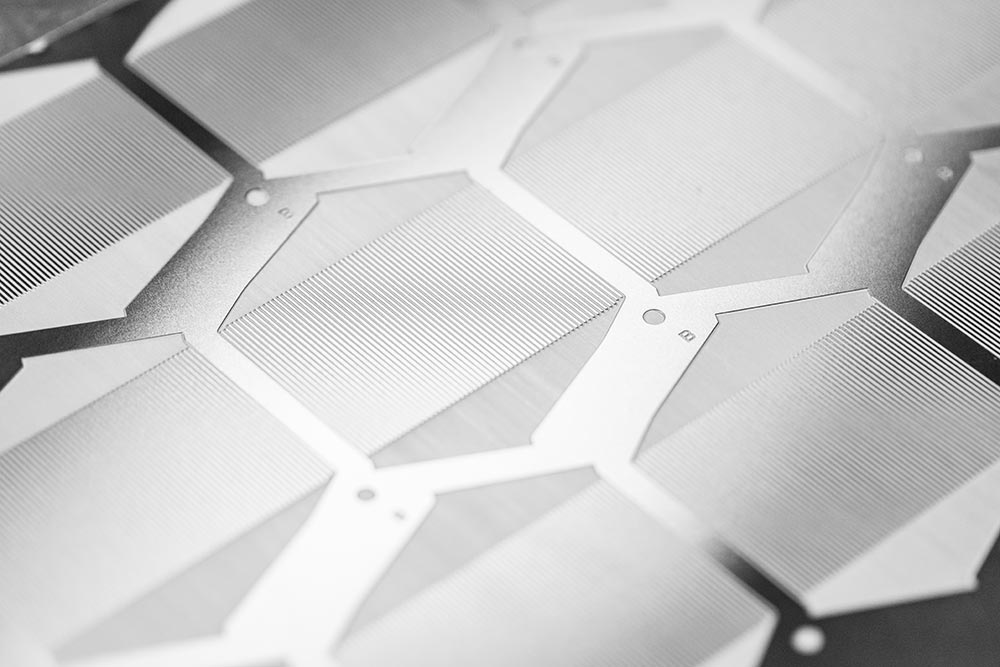

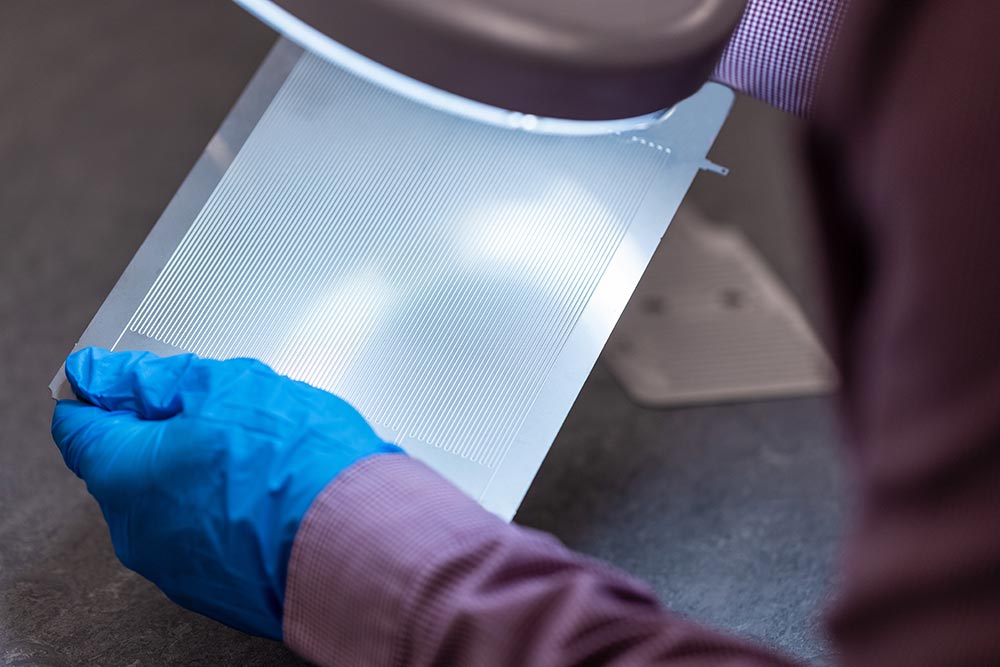

In partnership with leading fuel cell technology companies, Precision Micro is at the forefront of etching bipolar plates which are used to assemble individual PEM fuel cells – an alternative to batteries that do not run down or require a recharge, producing electricity and heat as long as fuel is supplied.

These etched plates are stacked in layers, with hydrogen applied to the anode side and oxygen on the cathode side. This results in a chemical reaction that produces electricity and releases a by-product of water. To ensure this happens efficiently, the plates must be machined with intricate channels to ensure the flow of gaseous fuel and air through the fuel cell.

Etching versus stamping and hydroforming bipolar plates

This state-of-the-art process ensures highly accurate production of plates at a high production rate, with channel and profile accuracy down to as little as +/-0.025mm. Also, unlike traditional metallic plate machining processes including hydroforming and stamping, etching does not affect the plate flatness or introduce stresses and burrs which could compromise stack bonding.

Supporting the commercialisation of hydrogen fuel cells

The use of fuel cells is not just limited to road cars, with the technology also being developed by the aerospace industry for next-gen aircraft, the construction industry for use in excavators, and even domestic boilers.

This is just a few of the reasons why fuel cell engineers should consider photochemical etching to produce bipolar plates, with Precision Micro playing an important role in commercialising this innovative technology.

Learn more about how chemical etching on bipolar plates can provide flexibility and savings in the automotive industry.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download