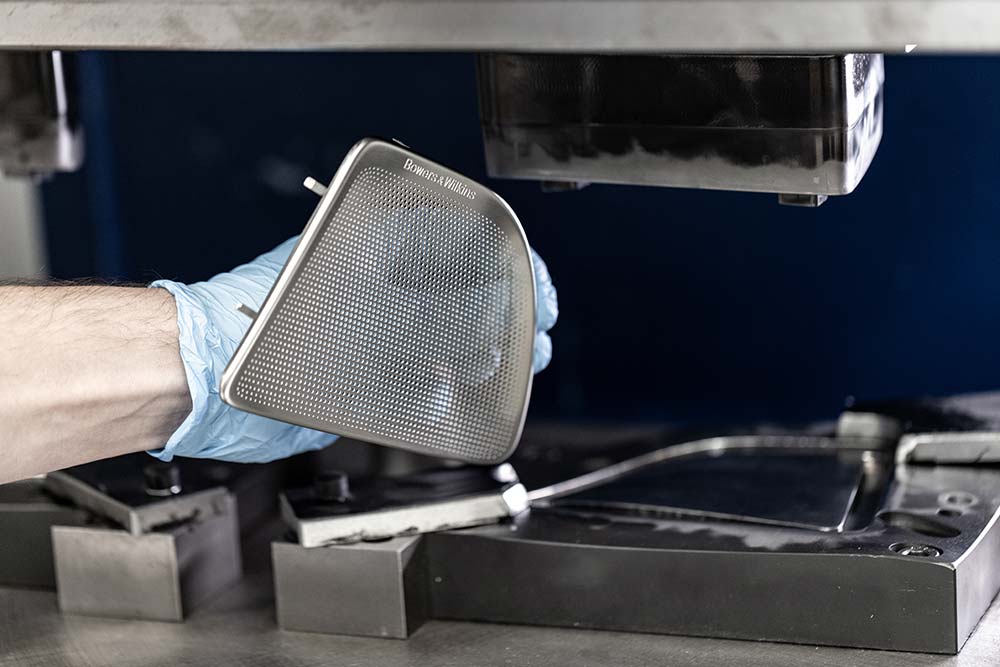

Speaker Grilles

Precision Micro is the market-leading supplier of photo-etched speaker grilles for world-renowned automotive marques, including Mercedes, Volvo, Jaguar and Rolls-Royce. Our chemical etching process specialises in providing high-quality, high-aesthetic interior trim components.

CONVENTIONAL SPEAKER GRILLE MACHINING

Metal speaker grilles are commonly found in the interiors of premium and luxury vehicles, providing numerous functional purposes whilst adding a high-quality aesthetic finish. Due to their high demand, speaker grilles necessitate large-scale production runs to ensure automotive manufacturers needs are met.

Until recently, speaker grilles were commonly manufactured using traditional stamping or punching. While stamping is favoured for its ability to handle large-scale production runs, it can negatively impact the aesthetic properties of speaker grilles, causing issues such as burrs, stresses, scratches and other part deformities.

PHOTO-ETCHED SPEAKER GRILLES

Utilising chemical etching, engineers can push the boundaries of speaker grille design. A versatile process, it has the capability to produce complex mesh patterns from almost any metal, whilst accommodating both small-scale and large-scale production runs with equal efficiency.

ECONOMIC TOOLING & PROTOTYPING

Photochemical etching eradicates the need for expensive hard tooling, instead using digitally produced photo tools. This offers endless design flexibility and the capacity to produce intricate designs and complex geometries, all at a fixed cost. Moreover, removing traditional hard tooling speeds up the prototype-to-production process, resulting in significantly reduced costs and lead times.

Benefits

Complexity without cost penalty

Low cost digital tooling

Rapid protoyping

100% burr and stress-free

ACCURACY & PRECISION

Photo etching uses renewable chemical etchants to selectively remove material from a metal sheet. This non-thermal, non-contact process eradicates the potential of deformities ensuring clean, 100% burr and stress-free parts. Furthermore, it offers unparalleled precision, achieving accuracies up to ±0.020mm and accommodating thicknesses ranging from 0.5mm to 1.0mm.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download