Chemical etching: What your competitors don’t want you to know!

One of the best kept secrets in manufacturing, chemical etching is the “go-to” technology for often complex, exacting precision metal parts and components produced by leading names across all key industry sectors. Your competitors probably already use it, but don’t want to share the benefits as to not give away the secrets of the technology enabling their products.

This article will detail everything that you need to know about chemical etching, and why it is opening up possibilities for design engineers that were previously deemed unattainable.

Introduction

There are numerous metal cutting technologies available to OEMs. Many of them are very niche in their application, often unable to process a sufficiently wide array of materials, or provide the accuracy and precision that is increasingly demanded by high-tech engineering sectors.

When benchmarking technologies that are able to produce “precision” metal parts the field is narrowed, the key players being universally recognised as stamping, punching, laser cutting and to a lesser extent, chemical etching.

Within the context of these alternatives, the unique characteristics of chemical etching overcome many of the issues associated with traditional metal cutting technologies, and as such — in some instances — when looking for a cost-effective solution for the manufacture of precision metal parts, etching is the only viable choice.

Let’s start with design

Before drilling down into the comparison between chemical etching and its traditional alternatives a little time needs to be spent reversing into the design department.

The best design in the world is only any good if it can be manufactured, and it is therefore up to the design engineer to ensure that the parts being designed are suitable to the manufacturing processes available. Therefore, it is fair to say that the constraint on the level of innovation is often the limitations of the available manufacturing technologies.

So, why choose chemical etching?

Chemical etching has many attributes that can truly stimulate innovation and ’stretch the boundaries’ with the inclusion of challenging product features, enhancements, complexity, and efficiency, and it is important that design engineers fully exploit its potential.

Very often, optimum success involves early stage engagement with a chemical etching specialist. A partnership needs to be forged, not a customer subcontractor relationship if the true potential of chemical etching is to be realised.

So, what are the key inherent characteristics of the chemical etching process that can be exploited at the design stage?

Chemical etching can be applied to a vast spectrum of metals in a variety of thicknesses and grades (typically sub 1.5 mm) in sheet sizes to 600 x 1500 mm.

Precision Micro stocks over 2,000 material types and in addition can supply specialist materials on request as well as work with customer materials on a case-by-case basis.

Accuracy — a key consideration in any design.

Standard etching tolerances of ±10% of the metal thickness are possible, to a minimum of ±0.025 mm. With development, greater accuracy can be achieved, as is component features to sizes below the standard minimum.

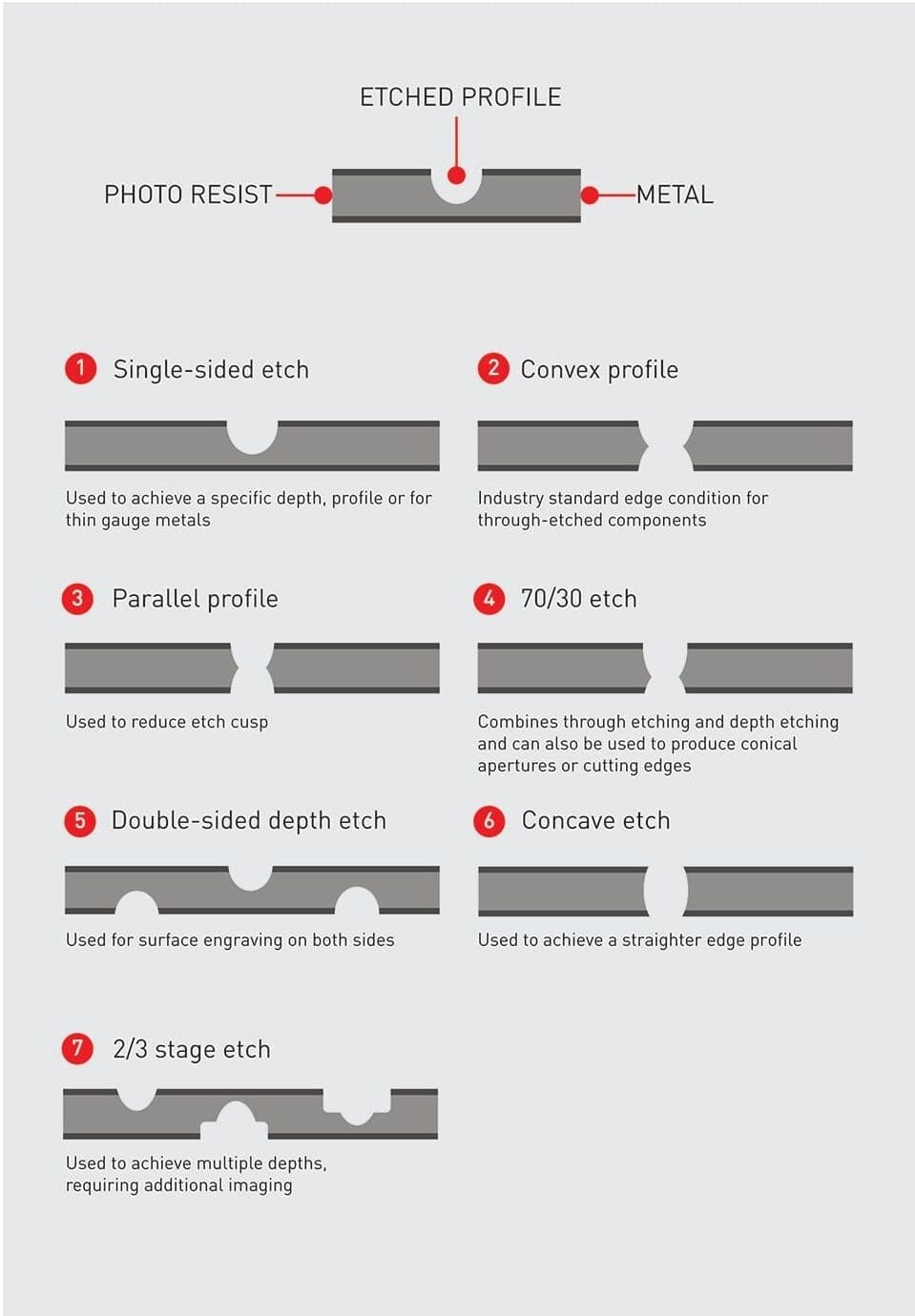

Design engineers also need to be aware of the inherent edge “cusp” created during the process.

Etch cusp can be controlled, and by so doing, a range of profiles can be introduced that allow the manufacture of sharp cutting edges such as those used in medical blades, or conical openings such as those used to direct fluid flow in filtration meshes.

Chemical etching not only copes well with difficult geometries, but it also allows design engineers enormous flexibility, facilitating the adjustment of designs right up to the point of manufacture due to the use of digital tooling – about which much more below!

Benefits and benchmarking

Chemical etching produces stress-free, flat components by selective etching through a photo-resist mask. It is especially well suited to the manufacture of precision parts such as grids and meshes, lead frames, bipolar fuel cell and heat exchangers plates, precision springs, washers and gaskets, and aesthetic parts such as automotive interior trim.

When compared with traditional metal manufacturing technologies, it has a number of inherent advantages.

- Metals suitable for etching can be both ferrous and non-ferrous and include austenitic and martensitic steels, coppers, brass and nickels. Hard to machine metals, such as titanium and aluminium, can be processed, and also high-temperature alloys such as Inconel.

- As an ambient temperature, no contact machining process chemical etching produces 100% burr-free, stress-free parts.

- Tooling for chemical etching is digital, so there is no need to start cutting expensive and difficult to adapt steel moulds. This means that large quantities of products can be reproduced with absolutely zero tool wear, ensuring that the first and millionth part produced are precisely the same.

- Also, as the tooling is digital, it can be adapted and changed extremely quickly and economically, making it ideal for the design engineer to tweak designs right up to the eleventh hour, but also making it ideally suited for prototype to high volume production runs.

The economy and adaptability of the tooling for chemical etching is a key stimulus to design freedom, along with the ability to produce what may seem like impossibly complicated products.

There are no barriers to entry with the technology. The cost of creating prototypes is low, and complex designs can be produced in a matter of days with designs iterations possible within a few hours.

Complexity without cost

More often than not, when using stamping, part complexity adds cost, whether in low, medium, or high volume applications. The complexity of a product means the necessity for a complex mould tool and complex tooling means increased costs, increased potential for tool failure and increased lead-times for satisfactory completion.

Chemical etching is unaffected by the level of tool complexity. It makes no difference in terms of costs or lead-time how complex the geometry of the part is and therefore the complexity of the digital tooling.

Chemical etching also has the ability to produce finer detail than is possible with stamping, and all with minimal if any degradation and deformation of the metal being processed. Failure rates are minute, and unlike in the stamping process, every part produced is absolutely flat, which in some applications is absolutely vital.

The “sweet spot” is in the manufacture of complex parts in small to medium sized production runs. In extremely high volume runs where the tooling expense is justifiable, and where designs are not overly complex, stamping typically represents a more economic process.

Conclusion

The advantages of chemical etching are its low cost, high speed, flexibility, suitability for complex designs and its ability to produce burr-free components, the properties of which have not been changed by heat or stress.

Standard lead-times for chemical etching technology is around to two working weeks, and even this can be shortened if there is urgent demand. For stamping, it can take months just to design, build and debug a tool.

Perhaps of greatest importance, however, are the possibilities that are opened up to design engineers to innovate through the use of this versatile and cost-effective metal processing technology.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download