Medical

Quality assured component supply from the widest range of medical-grade materials.

Contact UsTRUSTED TO DELIVER BY INDUSTRY LEADING NAMES

Precision Micro is dedicated to upholding stringent quality control and regulatory compliance as it delivers precise and cost-effective precision components to renowned companies in the medical industry.

Clean, precise manufacturing

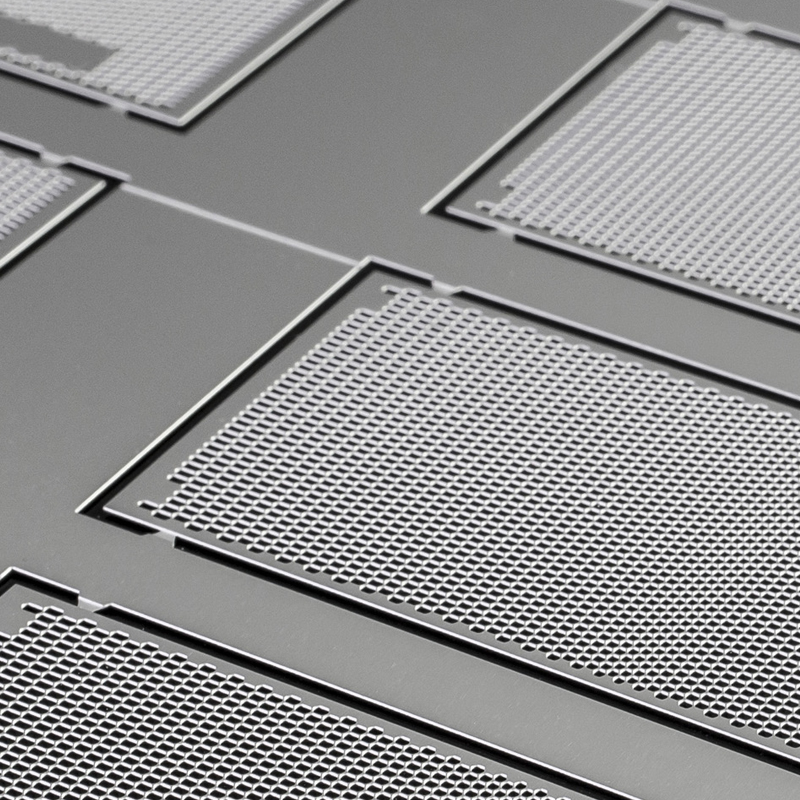

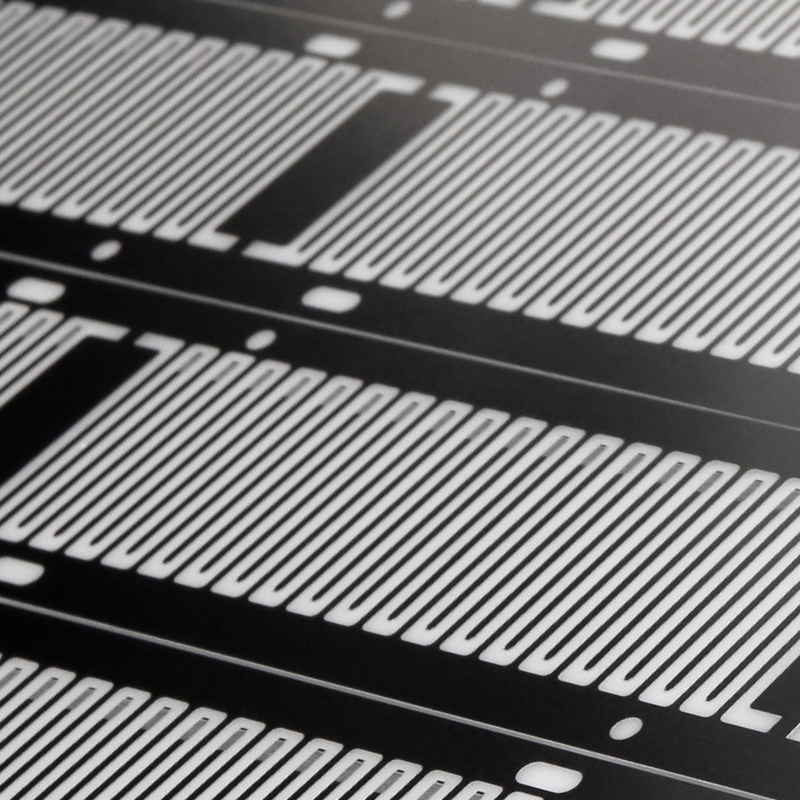

Chemical etching is a versatile and highly effective process for manufacturing medical components, offering several advantages. By selectively dissolving material from metal sheets using an etchant, it produces clean and precise medical components without the risk of recast layers, metal swarfs or chips that could impact performance.

With exceptional precision and the ability to create intricate designs without incurring extra costs, chemical etching surpasses the limitations of traditional manufacturing methods. This ensures the delivery of reliable and high-quality parts, free from burrs or stresses.

Learn more about chemical etching

Benefits

100% burr and stress-free components

Precision accuracy

Fast, flexible supply

Widest range of metals

Medical components

Our manufacturing expertise extends to a diverse range of medical components, ranging from current collector grids for pacemakers to sagittal and oscillating bone saw blades. In addition to chemical etching, we provide a comprehensive suite of post-processing services designed to enhance component performance and optimise functionality.

Filters, Screens & Sieves

Custom Metal Shims

PCB Shielding Cans

Flat Springs

Electrical Connectors

Medical Devices & Instruments

Photochemical etching medical grade materials

Metals and alloys play a crucial role in various medical components, offering the required strength-to-weight ratio, biocompatibility and corrosion resistance. Our versatile photo etching service caters to a wide range of metal types and grades, including 316 stainless steels for cleaner medical devices and ultra-hard Sandvik strip steels for precise medical cutting tools.

Download Accreditations

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download