Nickel Etching

Our nickel etching capabilities range from pure nickel to standard and specialist nickel alloys.

Contact UsPrecision Micro’s quality-assured nickel etching service is compatible with all nickel grades, ensuring the rapid production of burr and stress-free components.

How We Manufacture Nickel Components

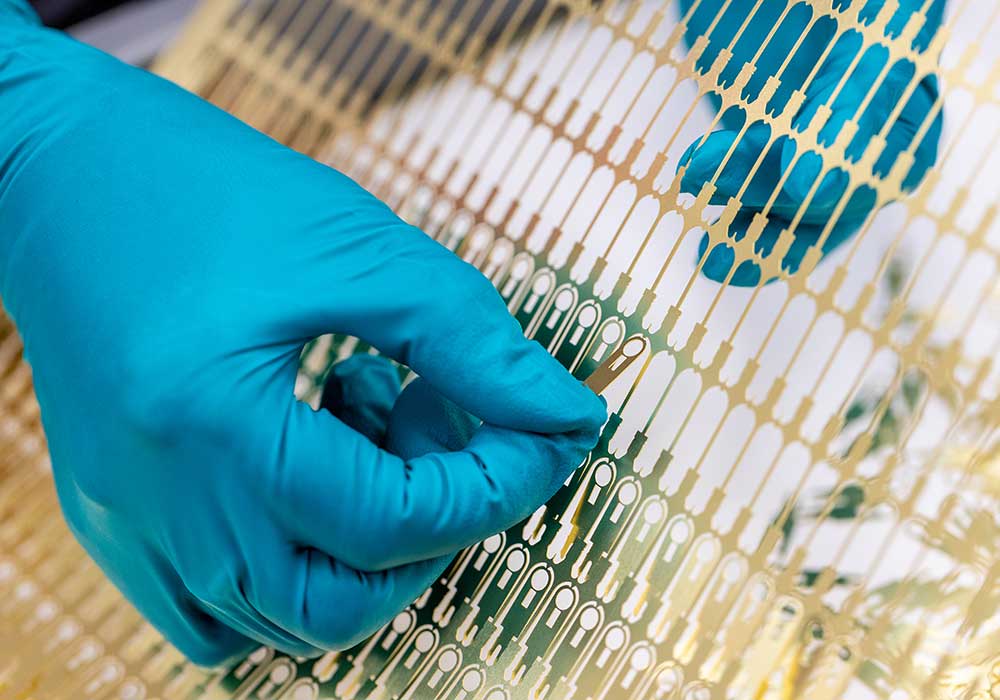

Our nickel etching process uses a controlled chemical reaction, selectively dissolving material from a metal sheet. This non-thermal, non-contact method removes the potential of burrs, stresses and other part deformities, leaving a smooth, high-aesthetic finish.

An Innovative Approach

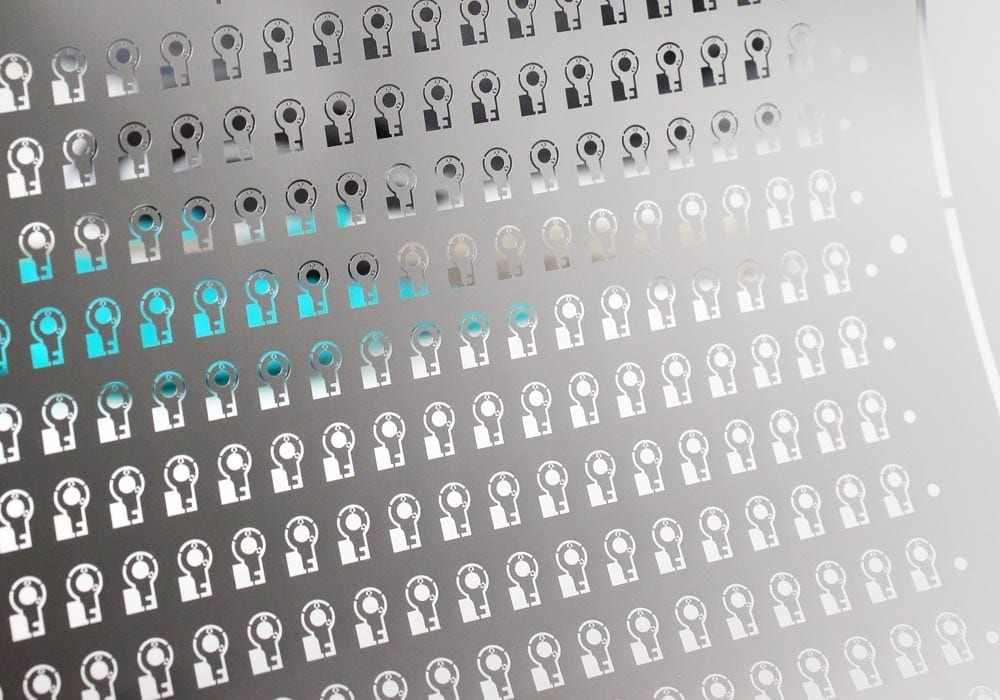

Photochemical etching utilises low-cost digital tooling, which enables us to offer a more flexible service than conventional machining methods, such as stamping. Digital tooling also reduces prototype to production lead times from weeks and months to a few days, whilst also offering limitless design complexity.

Nickel Grades Suitable For Chemical Etching

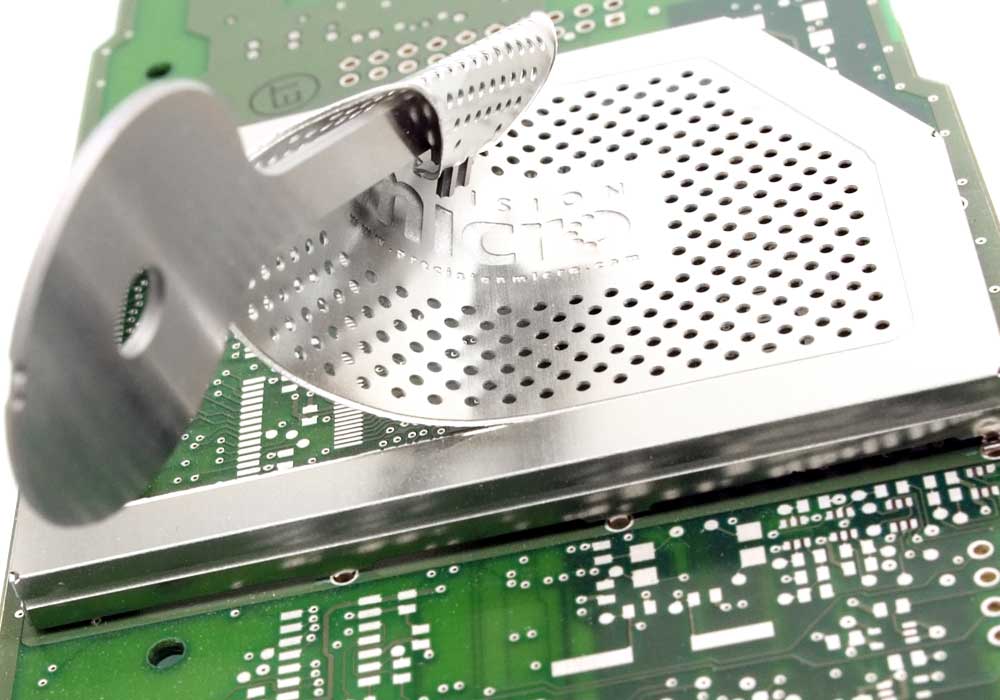

Our nickel etching capabilities range from pure nickel to standard and specialist nickel alloys, such as Inconel, renowned for its outstanding heat and corrosion resistance; nickel silver, the preferred material for board-level PCB shielding; and Kovar, an iron-nickel-cobalt alloy with a coefficient of thermal expansion similar to that of hard glass.

| Material | Grades/types |

|---|---|

| Alloy | 42, 52, 59, 151, 194, 195, 602 |

| Copper-nickel (cupronickel) | 90-10, 70-30, 66-30-2-2 |

| Elgiloy | – |

| Haynes | 25, 214, 230, HR120 |

| High Perm | 49 |

| Hymu | 80 |

| Incoloy | 800HT |

| Inconel | 600, 617, 690, 718, X-750 |

| Invar | – |

| Kovar | – |

| Monel | 400, 401, 404, K-500, 405 |

| Nichrome | – |

| Nickel iron | – |

| Nickel silver | All grades |

| Nickel | 200, 201, 205, 233, 270 |

| Nimonic | 90 |

| Radiometal | 4550 |

Etched Nickel Components

Photo etching offers endless opportunities for producing precise nickel components for a wide range of high-tech engineering applications, including EMI shielding cans, heat exchanger flow plates, connectors and contacts, precision shims gaskets and washers. Furthermore, our comprehensive service encompasses post-processing options like forming and plating, aimed at enhancing part performance and optimising your supply chain.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download