Precision Engineering

Cost-effective solutions for a diverse range of precision engineering applications.

Contact UsTRUSTED TO DELIVER BY INDUSTRY LEADING NAMES

From metrology to motion control, our photo-etched solutions have become the go-to choice for leading companies seeking exceptional quality and performance across a broad spectrum of precision engineering applications.

Supporting innovation

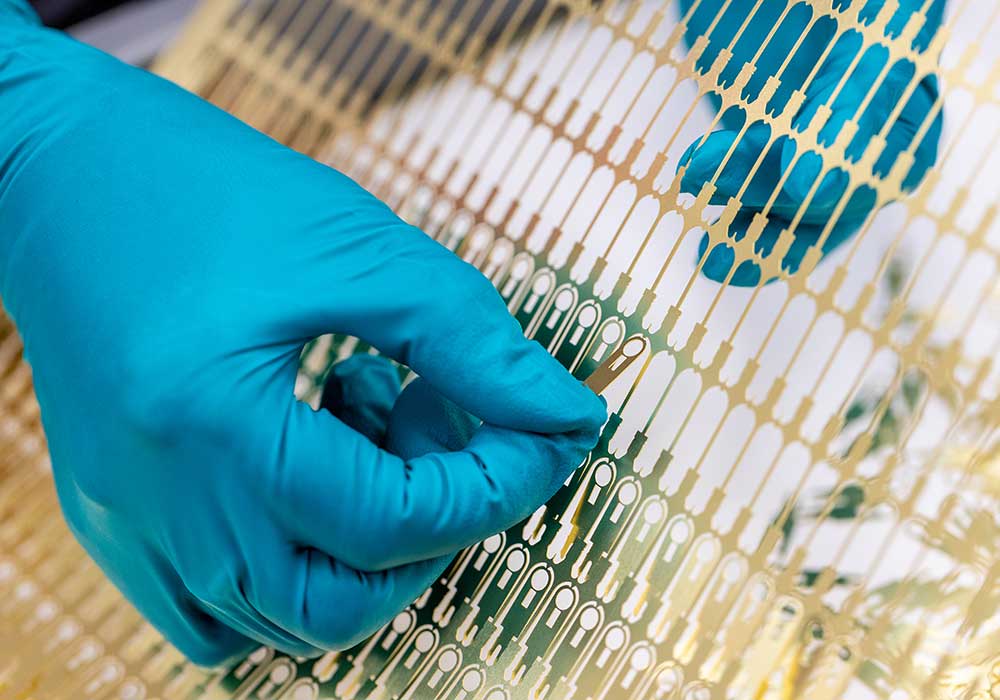

Precision engineering companies are at the forefront of technological advancements, developing intricate systems and devices that rely on precise metal components. However, design engineers often encounter difficulties in sourcing reliable, consistent and accurate parts within tight deadlines to bring their innovations to life. That’s where we step in.

A streamlined approach

Our chemical etching service provides a versatile and cost-effective solution for producing intricate parts from various metals. By utilising controlled subtractive chemical erosion and low-cost digital tooling, we can achieve high precision in manufacturing complex components without burrs or stresses. One of the major advantages of our streamlined approach is the significantly reduced turnaround time, measured in days rather than the extended lead times commonly associated with traditional machining methods.

Benefits

Fast prototype-to-volume production

Virtually any metal

Repeatability levels approaching Six Sigma standards

Added-value technologies for single-source supply

Precision engineered component solutions

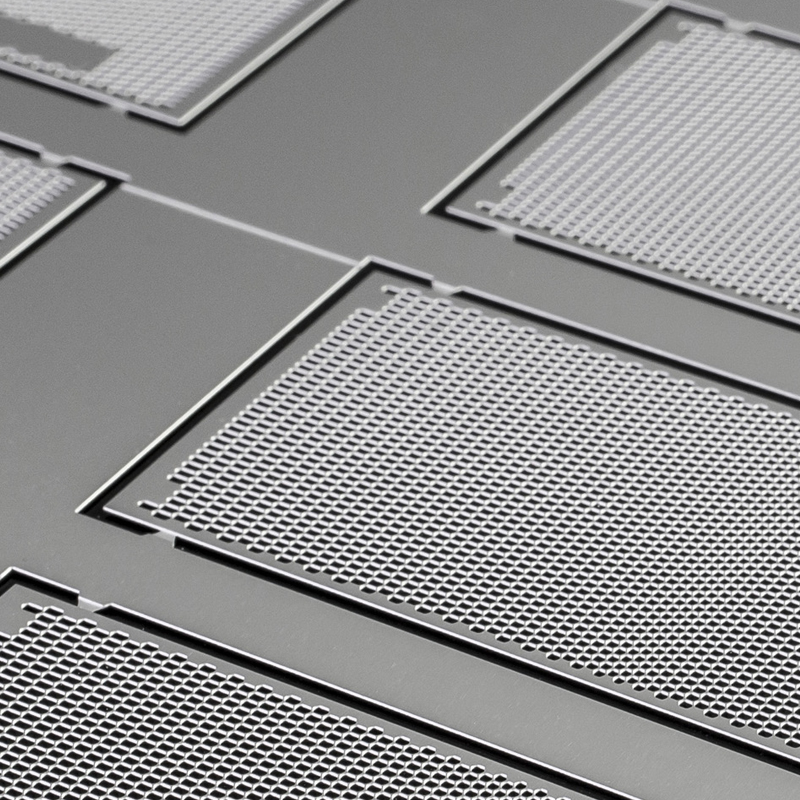

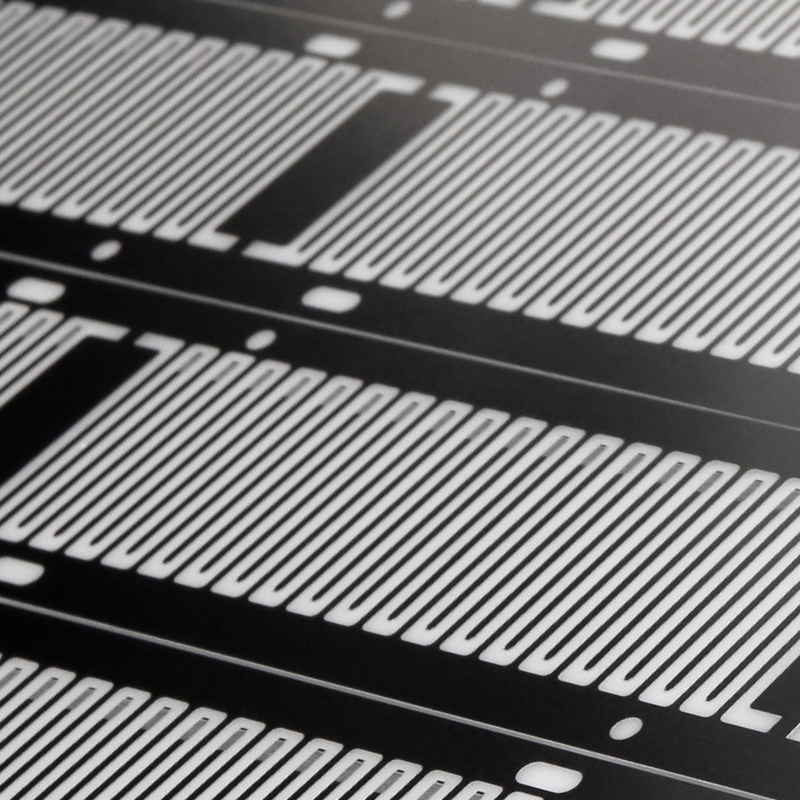

Our production capabilities extend to a diverse range of components, including meshes, filters, sieves, shims, gaskets, washers, springs, flexures, diaphragms, machine labels and more. We can seamlessly integrating all precision-engineered parts into our comprehensive post-processing services, ensuring optimised functionality and enhanced performance for your application.

Filters, Screens & Sieves

Custom Metal Shims

PCB Shielding Cans

Flat Springs

Electrical Connectors

Medical Devices & Instruments

Class leading quality

Our unwavering commitment to quality ensures that every part produced meets the highest standards. Our advanced inspection techniques and newly established Quality Centre of Excellence, equipped with cutting-edge vision measuring systems, guarantee and accuracy repeatability approaching Six Sigma standards.

Download Accreditations

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download