Quality in chemical etching: £1 million investment in quality and plant upgrades

Chemical etching is a process that creates high-precision metal components in any complex shape and pattern, with optimum quality.

Throughout the coronavirus pandemic, we continued to manufacture complex, high-quality and stress- and burr-free components for use in a variety of applications. Bolstering these efforts, we’ve progressed with our investment strategy and upgrade programme, investing in excess of £1 million into our UK facility.

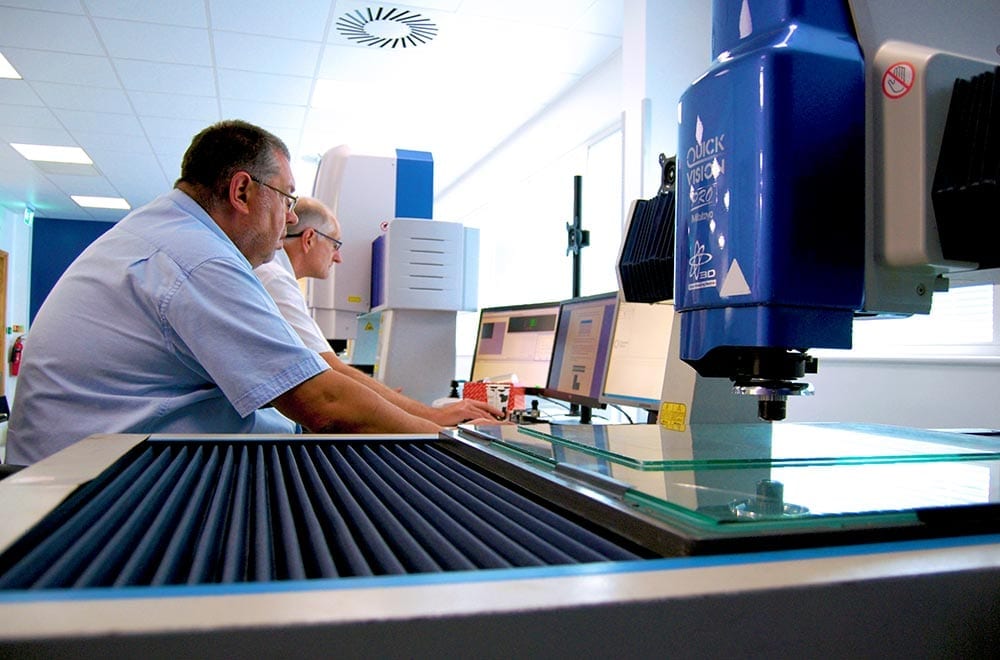

We have opened a new Centre of Excellence and invested in brand new state-of-the-art vision measuring systems. The Centre of Excellence strengthens our existing facility, equipping our business with increased optical CMM capacity to maintain consistently high levels of quality.

Helping businesses meet industry demand

As part of our upgrade programme, we have also reconfigured our site, moving offices to a new location on the same campus, in order to create additional manufacturing space. Because we’re based in Birmingham’s iconic Fort Dunlop building, we have a direct line of sight to the facility, helping us ensure a strong and seamless operation.

Our Managing Director, Ian McMurray, said: “During our annual summer shutdown, we’ve been able to put the finishing touches to this stage of our plan to upgrade our facility. We’ve moved some offices to another site and given our core facility over to manufacturing, with a host of new state-of-the-art process equipment brought in and a full-scale reconfiguration which streamlines our processes and strengthens our capabilities.”

If you need supply chain support to help you continue to deliver key services and projects, get in touch.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download