Custom Metal Shims

Precision metal shims from 0.010mm-2.5mm thick supplied fast to your design.

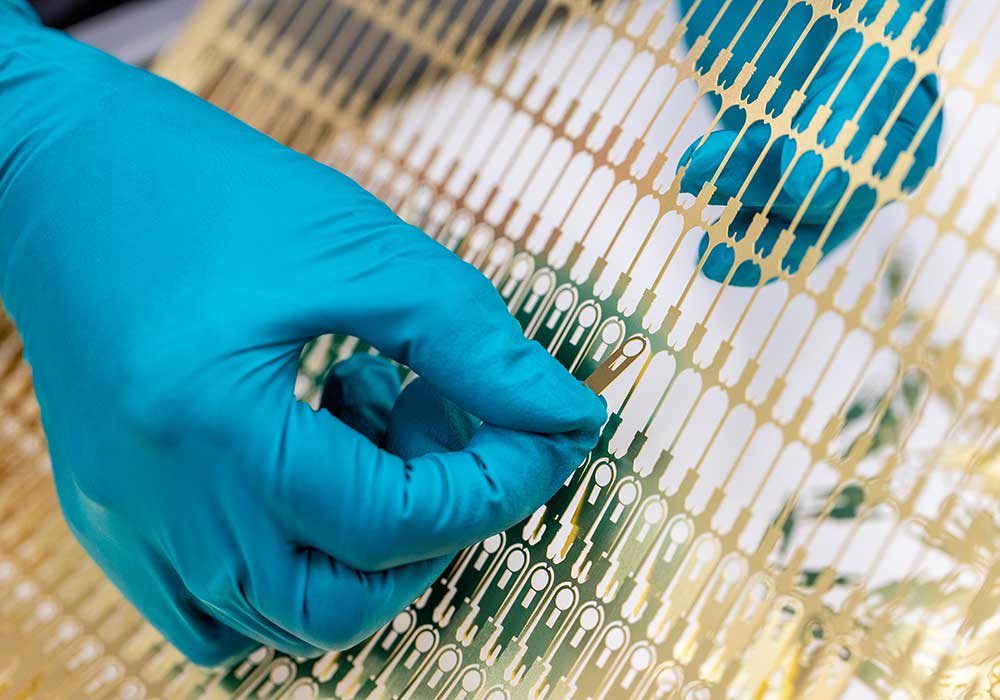

Request Pricing Application NoteWe manufacture a wide variety of custom metal shims, spacers and thin washer shims which can be supplied flat or formed to your design specification.

What are metal shims?

Precision metal shims serve as spacers between mechanical components, effectively absorbing impact, minimising “play” or movement and safeguarding material surfaces in advanced high-tech applications. They are commonly produced from diverse metal types, such as stainless steel, aluminium, brass or copper.

Economical & precise custom metal shims manufacturing

The flexibility of chemical etching means custom metal shims can be manufactured quickly using low-cost digital tooling. From simple spacer washers to complex steel shims for racing engines, our precision custom metal shims manufacturing service is accurate to ±0.020mm, producing flat and burr-free shims with no rough edges that could interfere with other mating components.

Metal shim materials

Whether you require stainless steel shim washers or aluminium shims, we can manufacture custom metal shims in every shape and size from 0.010mm to 2.5mm thick.

We etch over 2,000 material types, including all grades of ferrous and non-ferrous sheet metals, and hard to etch metals that offer corrosion resistance, wear resistance and more – perfect across a variety of industries.

Benefits

Lead-times in a few days

Low-cost digital tooling

Burr and stress-free

Accuracy to ±0.020mm

Metal shim forming & finishing

We offer a comprehensive range of forming and finishing technologies, including passivation, electropolishing and electroplating, ensuring all finished shims can be supplied from one single source.

Custom Metal Shims Application Note

Learn how chemical etching provides 100% specification satisfaction for metal shims production.

Download