Stainless Steel Etching

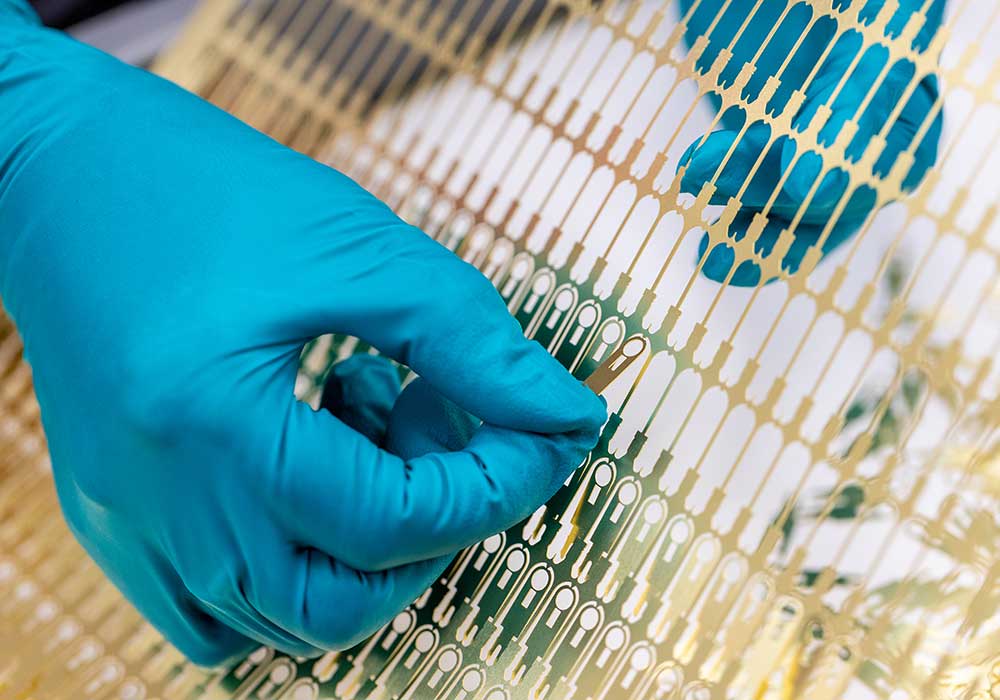

We offer a stainless steel etching service with unrivalled precision and accuracy.

Contact UsOur cutting-edge stainless steel etching process enables us to craft precise components while maintaining the integrity and corrosion resistance of all steel and stainless steel grades.

How We Etch Stainless Steel

Our stainless steel etching process begins by printing the desired component design onto a photoresist-laminated steel sheet. After development, the exposed surface of the steel is selectively removed using ferric chloride, a safe and recyclable etchant, while the laminated areas remain intact. This precise technique allows us to create intricate designs, microstructures or components with zero mechanical stress or burrs.

Versatile Manufacturing that Fosters Innovation

We can create components to meet your specific requirements, whether they are delicate and intricate or robust and functional. With endless customisation possibilities and a cost-effective approach that fosters innovation, our stainless steel etching process preserves the integrity of stainless steel. Components retain their corrosion resistance, ensuring long-lasting durability and suitability for various applications, even in harsh environments.

Suitable Steel & Stainless Steel Grades

Our expertise extends to chemically etching ferritic/martensitic, austenitic, duplex and precipitation hardened stainless steel grades. We are also equipped to work with specialist grades, including Sandvik Chromflex strip steels, and are open to processing customer-supplied metals.

| Material | Grades/types |

|---|---|

| Low carbon (mild) steel | All grades |

| Electrical steel | Transil |

| Maraging steel | All grades |

| Sandvik strip steel | Chromflex (7C27Mo2, 13C26, 12C27, 6C27), Hiflex |

| Uddeholmstrip flapper valve steel | 20C, 716 |

| High carbon (spring) steel | All grades |

| Stainless steel | Austenitic (300 series), ferritic/martensitic (400 series), precipitation hardened (17-4, 17-7), duplex, super duplex |

Precision Applications

From aerospace and automotive to electronics and medical devices, our etching process is widely utilised for the production of stainless steel components. Whether it’s surgical instruments, automotive parts or electronic connectors, our stainless steel etching service delivers the reliability and quality that your applications demand.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download