Chemical etching FAQs

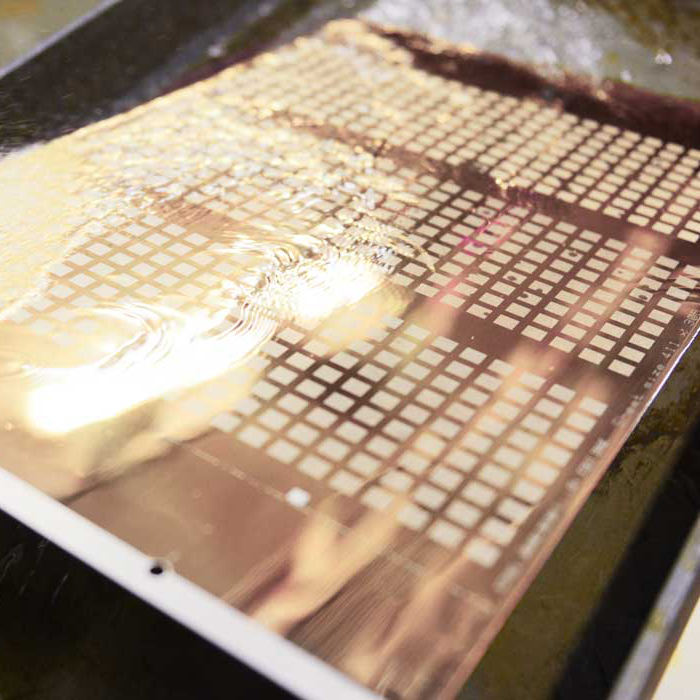

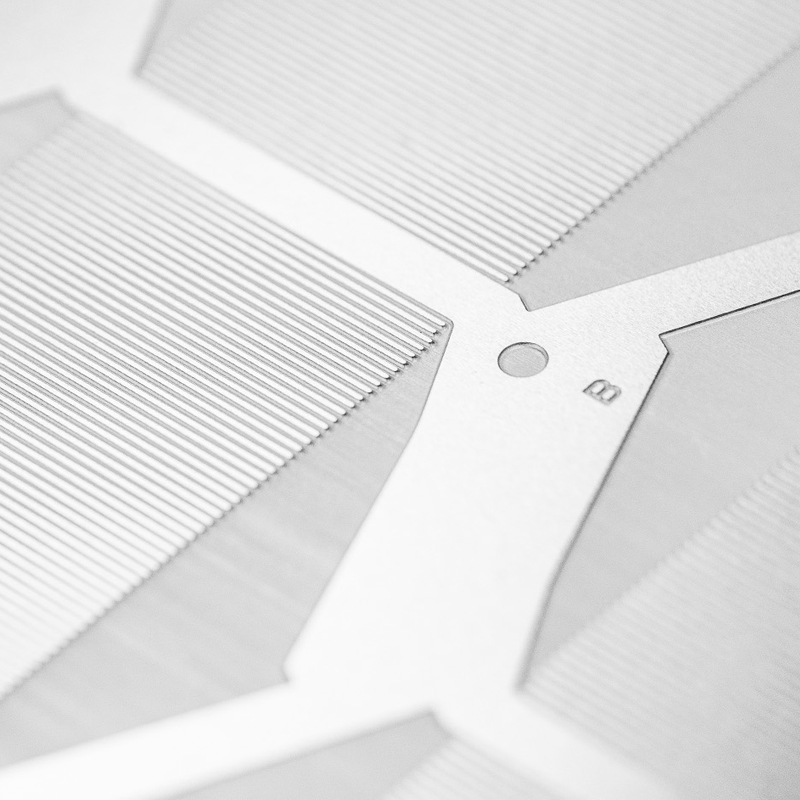

Sheet metals between 0.010 mm and 2.5 mm thick, and up to 600 mm x 1500 mm in size are suitable for chemical etching.

The thicker the part the longer it takes to etch, meaning metals above 2.5 mm are often uneconomical to process.

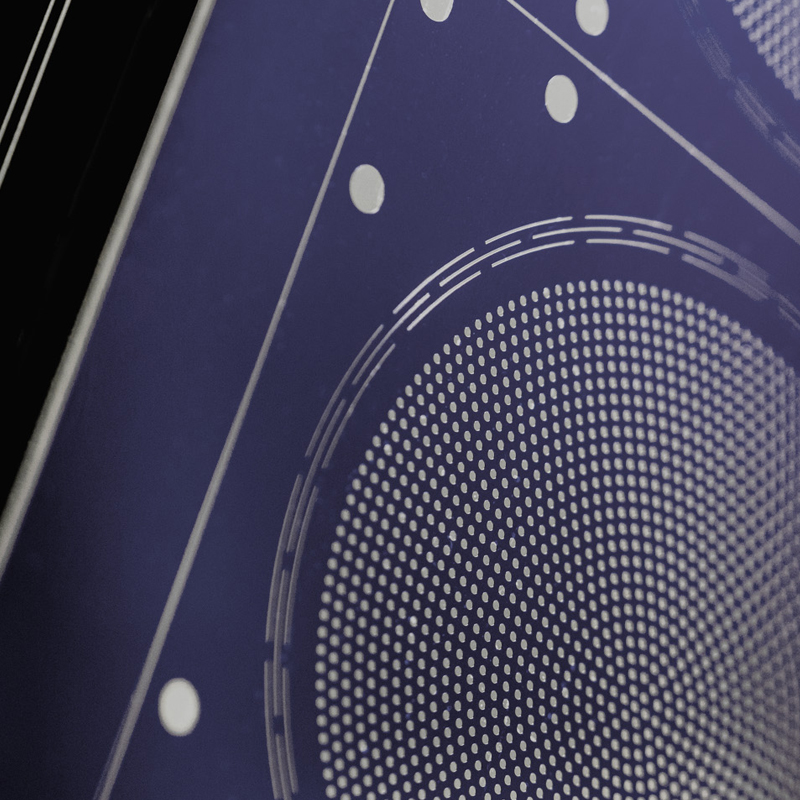

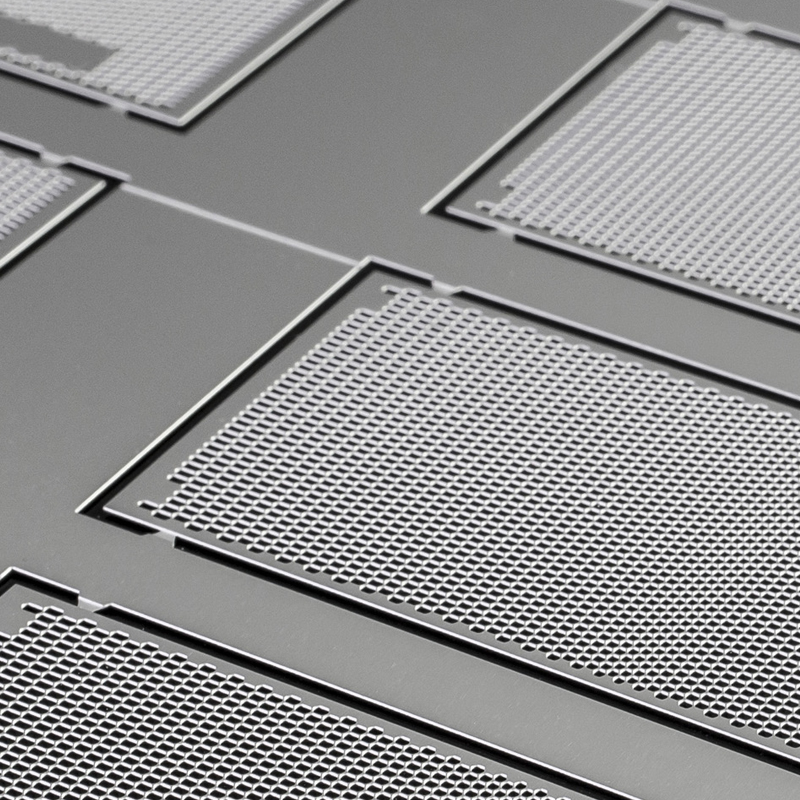

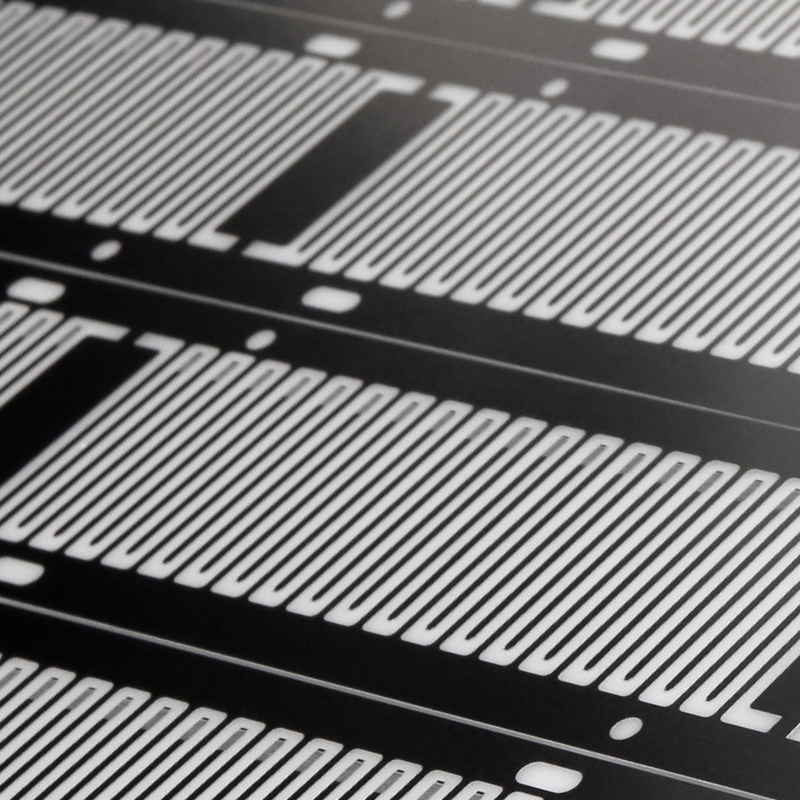

Photochemical etching can achieve exceptional accuracy. The standard minimum etching tolerances stand at ±10% of the metal thickness or ±0.020 mm, whichever is greater.

To push accuracy boundaries further, we strongly advise involving Precision Micro’s engineers right from the outset of your design process. This collaborative approach allows us to develop a customised manufacturing process that aligns with your specific requirements.

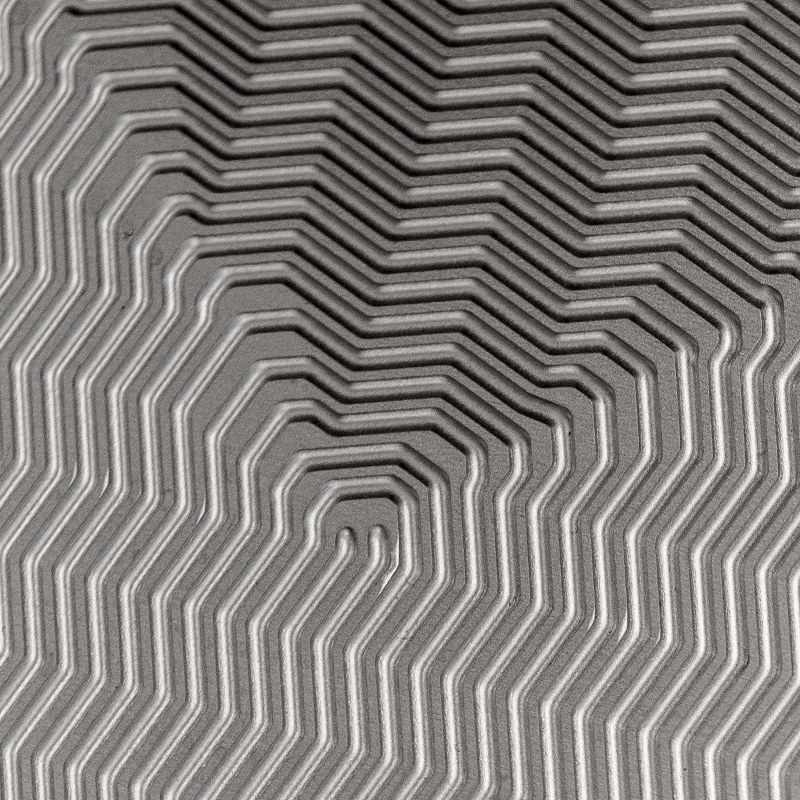

The minimum standard etched opening achievable is 0.1 mm, or 0.020mm for depth-etched features such as microfluidic channels. Again, with development etching can achieve even finer features.

Chemical etching offers unrivalled flexibility, allowing the production of components without any minimum or maximum quantity limitations.

At Precision Micro, we take pride in our ability to cater to a wide range of demands, delivering component quantities that span from single units to millions. Our streamlined manufacturing processes ensure that no matter the scale, each component receives the same level of precision and quality.

When considering cost in chemical etching, material type, thickness and component size play crucial roles. Thicker sheets often require more etching time, while ultra-thin sheets may involve additional processing steps, both contributing to higher overall component costs.

At Precision Micro, our experienced team can guide you through these considerations, ensuring the best possible outcome for your project.

Chemical etching offers lead times measured in days, not weeks or months, setting it apart from traditional metal machining technologies.

For standard components that require no additional post-processing, our typical supply time is less than two working weeks, depending on our production capacity and material availability. However, in situations where urgent demands arise, we are fully equipped to expedite the process, providing even quicker turnaround times.