5 reasons why electronic component manufacturers can’t overlook chemical etching

In today’s interconnected world, the demand for electronic devices and systems is rapidly increasing across all industry sectors. Consequently, electronic component manufacturers face the challenge of selecting the most efficient and cost-effective manufacturing processes that guarantee optimal performance.

In this post, we explore the five reasons why electronic component manufacturers can’t overlook chemical etching.

1. Material versatility

Etching is a versatile process that can work with almost any metal, making it an ideal choice for creating electrical components. Unlike traditional machining methods such as stamping and laser cutting, which may encounter challenges when dealing with hard, soft, or brittle metals, etching is not limited by the properties of the materials used.

Copper is one of the most popular metals used in the production of electrical components due to its excellent electrical conductivity. Although copper tends to oxidise, its corrosion resistance can be improved through post-process plating.

Etched copper components such as lead frames, EMI/RFI shielding cans, and busbars are commonly found in numerous electrical systems.

Beryllium copper (BeCu) is a highly conductive copper alloy that is durable and easy to form post-etching, making it ideal for electrical contacts.

Brass is a copper and zinc alloy known for its high electrical and thermal conductivity, strength, and corrosion resistance. Brass is easily formed and maintains its shape, making it ideal for contacts, connectors, and busbars.

A bronze alloy containing copper and zinc, phosphorous bronze has superior spring qualities, high fatigue strength, excellent formability, and high corrosion resistance. These attributes make it a great option for producing battery contacts and springs.

Nickel silver (also known as German silver) is a copper, nickel, and zinc alloy used in electrical components such as EMI/RFI shielding thanks to its high corrosion resistance and solderability. Moreover, the material is malleable, ductile, and nonmagnetic.

Although steel is not as conductive as other materials, adding tin plating significantly enhances its conductivity and solderability. Cold-rolled steel, known for its strength, also possesses high formability, spring properties, and shape retention.

Stainless steel is highly resistant to corrosion and has excellent thermal conductivity, making it a popular choice to produce precision metal shims, springs and filters.

2. Zero thermal stress

The high temperatures associated with traditional machining methods can cause material deformities due to thermal stress. This can impact the performance of the metal component.

Chemical etching eradicates the potential of parts being affected by thermal stress.

The process dissolves the metal parts simultaneously rather than at localised points of contact. In contrast, processes such as laser cutting and wire EDM can introduce thermal stress along the edges, which, although minor, may interfere with functionality.

3. Zero burrs or micro burring

Another issue with using traditional machining processes is the potential of burrs which can negatively impact the performance of electrical components. For example, laser cutting can leave micro burrs on the metal’s surface, while stamping can leave partial burring. Even slight burring can cause several issues, such as electrical short circuits, interference interruptions, plating build-up at the component’s edges, decreased formability, inaccurate dimensional tolerances, and scratches on the surface that can affect mating components.

Photochemical etching dissolves unwanted materials on a molecular level, resulting in smooth surfaces and a precision-etched profile, eliminating the need for secondary deburring operations.

4. Suitable for thin materials and complex designs

Electronic devices have become progressively smaller, resulting in a need for small-scale, lightweight components with complex designs. These microelectronic parts are usually machined from thinner metals and require tighter dimensional tolerances.

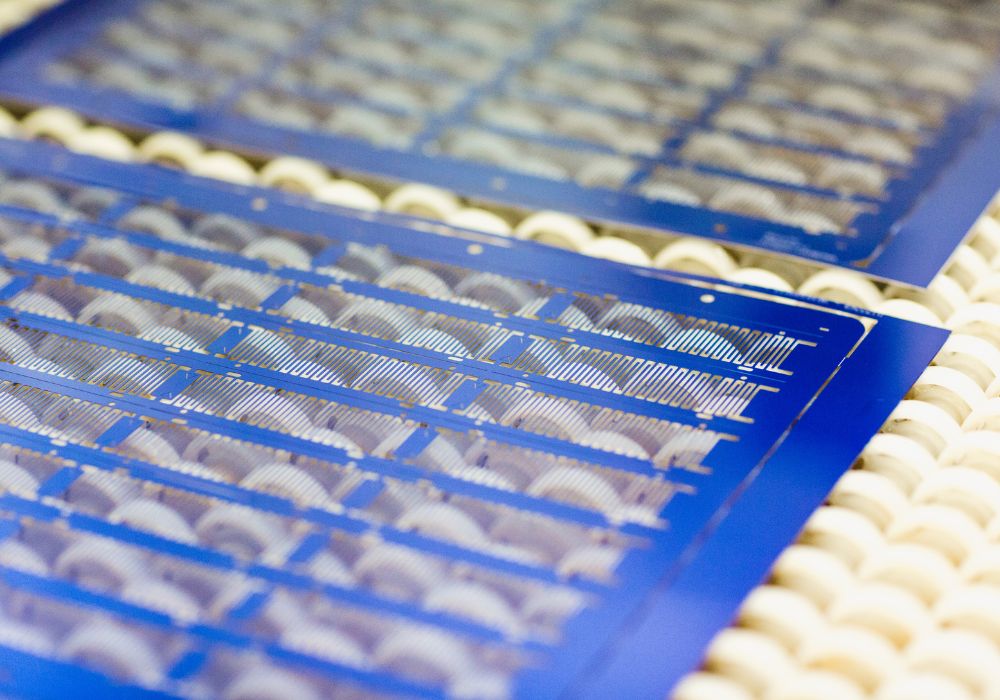

Chemical etching is the optimum process for producing microelectronic components with complex patterns such as lead frames and filters. This process enables the simultaneous machining of features such as holes and slots saving time and money compared to using alternatives such as laser cutting, wire EDM, and stamping.

In addition to this, chemical etching offers the ability to partially etch a metal surface, creating fold lines. These half-etched features are particularly valuable in electronic components which require forming, as the metal can be modified efficiently without sustaining any deformities.

5. Easy to modify tooling and rapid prototyping

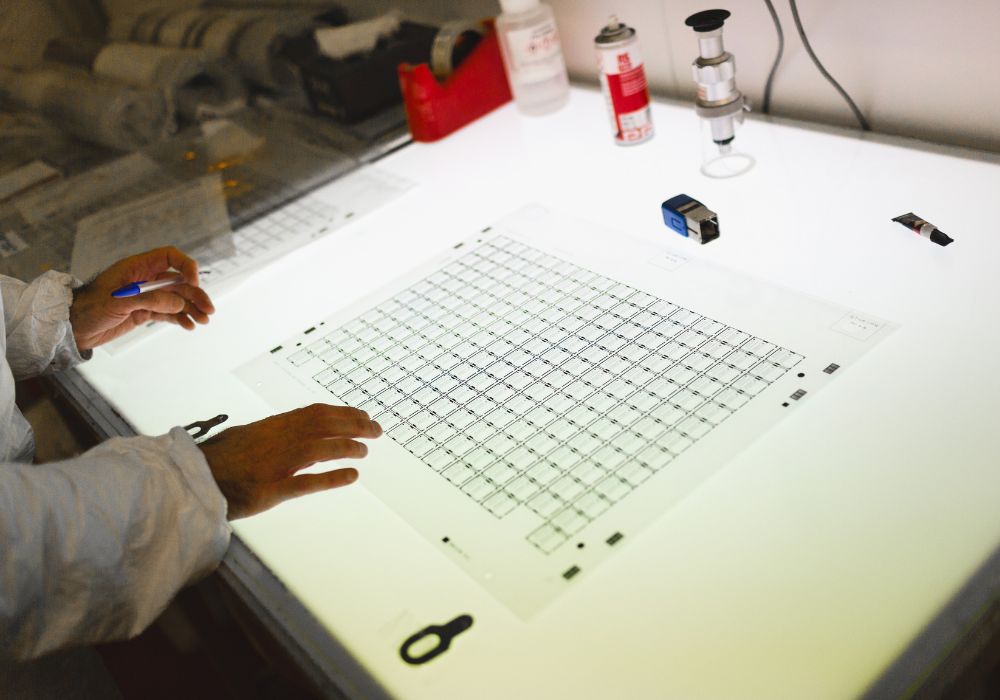

The ability to test and modify designs cost-effectively is an essential step in the prototyping stage. Chemical etching makes it easy to revise electronic parts using low-cost digital photo-tooling.

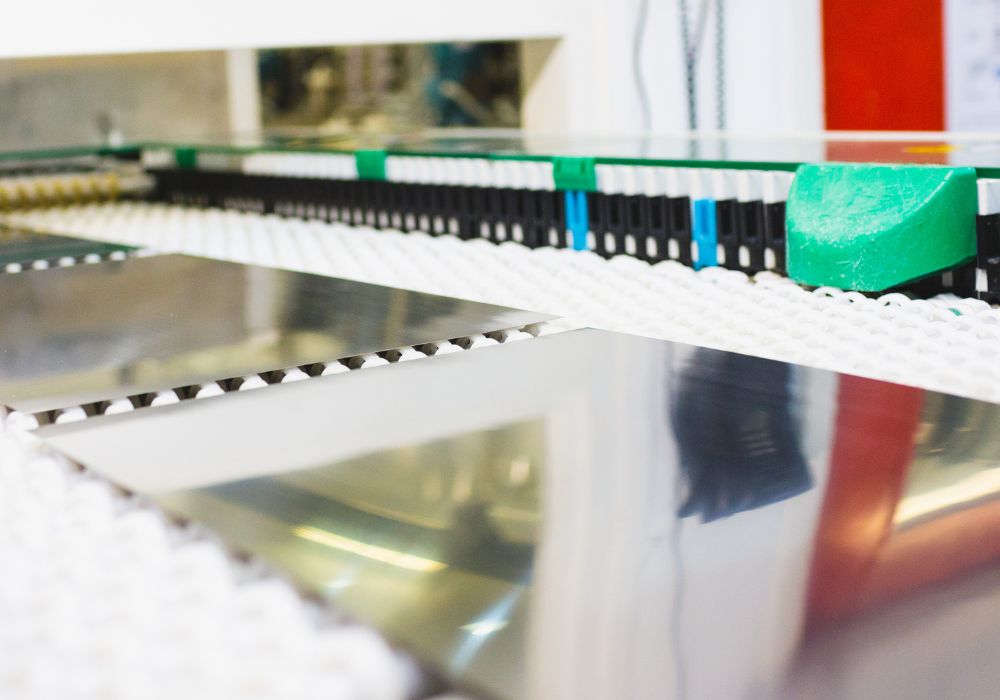

The process also allows for multiple-part designs that require the same material and thickness to be placed on the same tooling, reducing costs and lead times.

Summary

Chemical etching is a highly versatile and innovative process that electronic component manufacturers should consider for creating a wide range of electronics and microelectronic components. The process offers a variety of metal etching material capabilities, is resistant to thermal stress, remains burr-free, is suitable for thin materials and complex designs, and allows easy modification of tooling and fast prototyping. By taking advantage of these benefits, OEMs can select the most efficient and cost-effective manufacturing processes that guarantee optimal performance.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download