What are the technical considerations for photochemical etching precision metal parts?

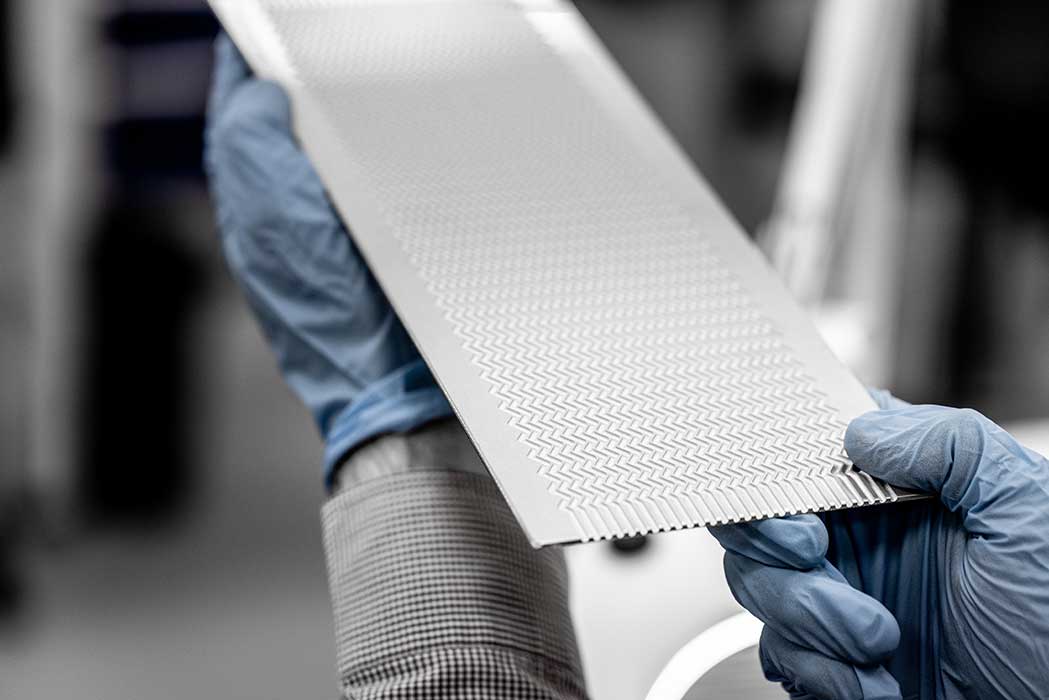

Photochemical etching, also known as photochemical machining or photoetching, is a process that uses a combination of light and chemicals to selectively remove material from a substrate.

It is commonly used in the manufacturing industry to create high-precision metal parts, including electronic components, aerospace parts and medical devices. While photochemical etching offers many advantages over traditional metalworking methods, it also requires careful consideration of several technical factors to achieve the desired results.

Designing for photochemical etching

The first step in photochemical etching is to create a design for the part that will be etched. This design must consider several technical considerations, including the thickness and type of material being used, the desired level of precision, and any post-processing required. It is important to work closely with an experienced etching supplier to ensure that the design is optimised for the photochemical etching process.

Material selection & sizing

The substrate material used in photochemical etching must be compatible with the chemical solution. Typically, metals such as stainless steel, copper, and brass are used in photochemical etching, but it is also possible to etch non-standard metals with specialist chemistries.

Click here for a full range of metal types suitable for photochemical etching.

Generally, chemical etching is best suited to thin materials ranging from 0.01mm to 2.5mm thick, with a maximum sheet size of 1500mm x 600mm.

The thickness and size of the material can also affect the cost of the etching process, with thinner materials requiring less etchant exposure time. Subject to design, thicker materials may require multiple etching steps or longer exposure times to achieve the desired pattern or design.

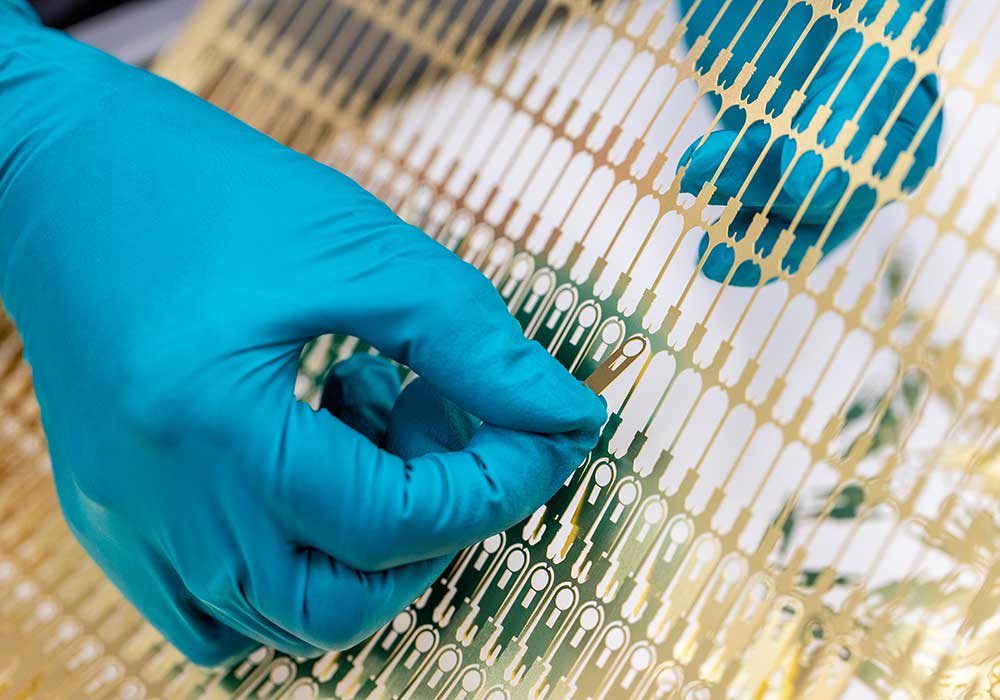

Feature size & accuracy

Chemical etching can create features which are much smaller than traditional mechanical machining techniques. Sizes as small as a few microns can be produced, with the smallest etched feature size being determined by the material thickness and having a typical 1:1 ratio. The accuracy of any through-etched feature can be down to ±10% of the material thickness or a minimum of ±0.025mm.

For depth-etched features, the material thickness becomes less significant. Surface features such as fluidic channels can be etched to a depth of 0.025mm, however; the width of any etched depth will increase in size at a 2:1 ratio. For example, a 0.025mm depth will have an etched width of 0.050mm.

The complexity of the design is another factor that can impact the achievable feature sizes with chemical etching. Simple designs with straight lines and curves can be etched with greater precision than complex designs with irregular shapes, patterns, and profiles. The size of the part being etched also affects the level of precision achievable, with larger parts often requiring a greater minimum etching tolerance.

Etch ‘cusp’ and inside/outside corner radii

During the etching process, the metal is not only etched downwards but also etched sideways, creating a v-shaped ‘cusp’ around the perimeter of the cut. This effect is known as the ‘undercut’.

The undercut, which is controllable, can be used to produce a variety of profiles, providing products with unique characteristics such as sharp cutting edges or conical openings.

The etch cusp also impacts the inside and outside corner radii of a component produced, with a minimum inside corner radii proportional to the thickness of the material. A minimum outside corner radii of 75% is typical.

Etch tags or tie ins

An etch tag, sometimes referred to as a tie-in, is a small protrusion or indent left behind on a part after being etched. Etch tags are used to hold parts in place during the etching process or to aid in post-etching processing steps, such as part identification or assembly.

Subject to the component size, design or tolerance requirement, components can be produced without tags; however, they are usually essential when the required tolerance is less than 15% of the metal thickness.

Summary of photochemical etching technical design considerations

In conclusion, photochemical etching is a highly precise manufacturing process that can produce intricate metal parts for a variety of industries. While the process offers many benefits over traditional metalworking techniques, careful consideration of several technical factors is required to achieve the desired results. Material selection, feature size and accuracy, etch cusp and corner radii, and etch tags must all be considered when designing a part for photochemical etching. By working closely with an experienced supplier, the benefits – and cost savings – of photochemical etching can be maximised to create high-precision metal parts for any application.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download