Motor lamination manufacturing processes: A comparison of stamping, laser cutting and chemical etching

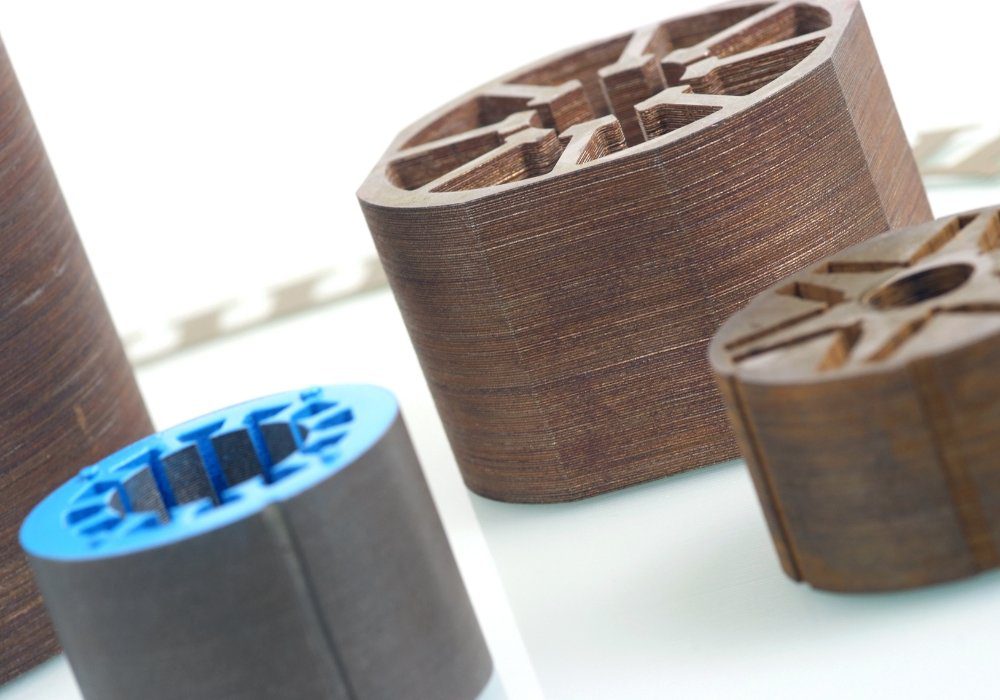

Motor laminations are critical components of an electric motor’s stator and rotor, playing a vital role in enhancing its efficiency by limiting the size and strength of induced eddy currents, which can lead to power loss and generate waste heat.

Typically created by bonding together thin metal layers which form the electrical core, these components are widely used in a range of applications, from electric vehicles to industrial machinery. In this post, we’ll explore the three most common motor lamination manufacturing processes used to produce stator and rotor laminations: stamping, laser cutting, and photochemical etching.

Stamping motor laminations

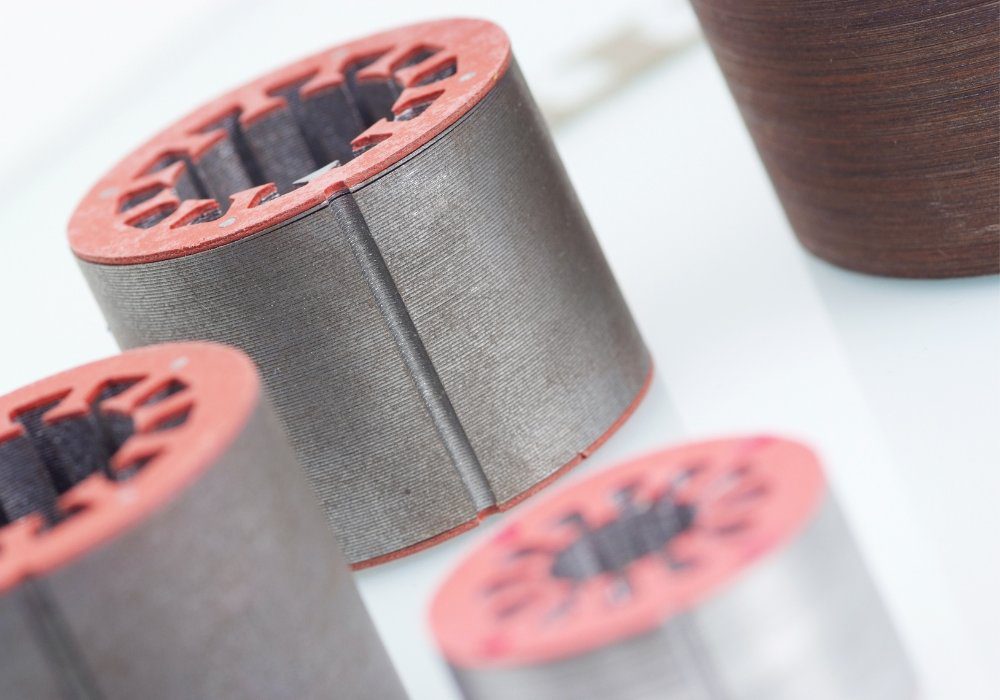

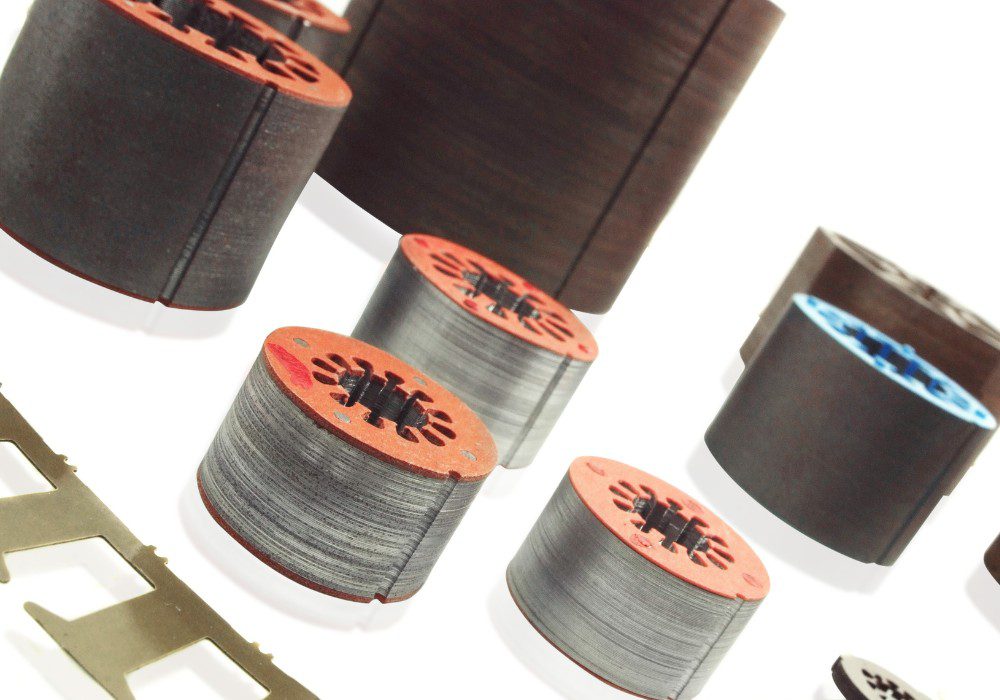

Stator stamping is a traditional machining manufacturing process used to produce motor laminations. The process involves using a die, a specialised tool made from hardened steel, to cut the laminations from a sheet of metal. The die is specifically designed, shaped, and sized to meet the desired specifications of the stator lamination, ensuring the component is accurately cut from the sheet. This process is repeated for each lamination resulting in a stack which is bonded together, creating the electric motor core.

Stamping is quick and efficient, making it an ideal choice for high-volume production runs. However, the process is limited in terms of its high tooling set-up costs, increased lead times, and the potential for cutting-edge stress.

Laser cutting motor laminations

Laser cutting is another traditional machining process which is used to manufacture motor laminations. The laser cutting process begins by using computer-aided design (CAD) software to develop a precise and accurate tool meeting the requirements of the specification. Once complete, the CAD file is sent to the laser cutting machine, which uses a high-powered laser to cut the desired shape and size from the metal sheet. Like stamping, this process is repeated, and eventually, all the rotor laminations are bonded together to form the electric motor core.

Laser cutting is a highly precise, flexible, and accurate method for producing motor laminations, resulting in consistent high-quality results. However, there are some potential drawbacks to laser cut stator laminations which must be considered, such as the potential of thermal stress that can affect the magnetic properties of the motor stator laminations.

Chemical etching motor laminations

Photochemical etching, a lesser-known sheet metal machining process, involves selectively removing metal from a sheet using an etchant. The process is used to produce motor laminations due to its ability to manufacture precise and intricate designs accurately and consistently. A sheet of metal is coated in a layer of ultraviolet-sensitive photoresist, which is exposed to a pattern of light printing the design onto the sheet, causing some areas to harden and others to remain soft. The soft areas are then removed before ferric chloride is sprayed onto the sheet, selectively removing the metal. In the final step, the remaining photoresist is removed leaving behind the etched motor lamination.

Eliminating cutting and thermal edge stress from motor stator lamination production

One of the main benefits of using chemical etching as a stator lamination manufacturing process is the elimination of cutting-edge and thermal stress that can arise during stamping or laser cutting. Unlike these traditional manufacturing processes which involve contact or thermal energy, chemical etching is a non-contact, non-thermal process that utilises a chemical solution to remove metal from the surface of a sheet. As a result, the finished component has a smoother, more precise finish and can help to preserve the magnetic properties of the metal.

In addition, eradicating the potential for cutting-edge and thermal stress provides a more consistent and streamlined production process, improving overall efficiency.

Flexibility in motor lamination design and production

Another advantage of photochemical etching is its flexibility and ability to work with a wide range of materials including nickel alloys and silicon steels. This flexibility provides greater options for the design and production of rotor laminations, allowing for customisation to meet specific needs that may not be possible with other manufacturing methods like stamping or laser cutting.

Etching simplifies the modification of tooling as it does not require the need for expensive hard tooling or reprogramming of machinery. Since the process does not require expensive tooling equipment, it helps reduce costs and minimise lead times.

Conclusion

In conclusion, chemical etching provides numerous advantages over traditional machining methods such as stamping and laser cutting when manufacturing motor laminations. This non-contact, non-thermal process eliminates cutting-edge and thermal stress, resulting in consistent, high-quality finishes that preserve the metal’s magnetic properties. Etching is also flexible, allowing for the accurate production of intricate designs with a wide range of materials. Furthermore, it simplifies tooling modifications, reduces costs, and minimises lead times making it a viable solution for industries seeking efficient and cost-effective manufacturing methods to improve motor lamination production.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download