A guide to photchemical etching for design engineers

This photochemical etching guide highlights the key features design engineers must consider to get the most from the etching process.

For an in-depth guide to the photochemical etching process, download our FREE whitepaper here.

Introduction

Photochemical etching is a highly repeatable and versatile etching process that can cost-effectively manufacture precision metal components for a wide range of mission-critical or safety-critical applications.

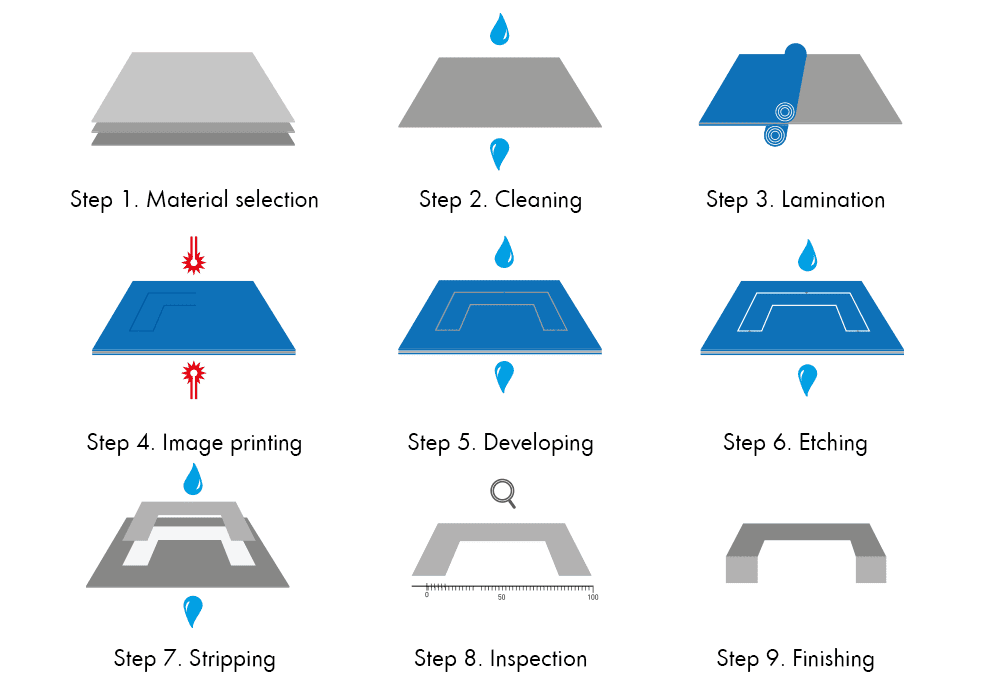

The process involves selectively removing material from sheet metal using a photosensitive resist and chemical etchants to create intricately detailed and precise components.

Suitable Materials for Photochemical etching

Unlike traditional sheet metal machining processes, photochemical etching can be applied to virtually any metal that is soft, hard or brittle. The process is generally not suitable for precious metals such as gold.

Click below to learn more about etching each material type or view a detailed list of metals and grades suitable for photochemical etching.

- Steel and stainless steels

- Aluminium

- Nickel and nickel alloys

- Copper and copper alloys

- Titanium

- Other specialist metals, such as molybdenum

How accurate is photochemical etching?

With photochemical etching, achievable tolerances often relate to material thickness.

- For metals 0.01 mm to 0.25 mm in thickness, the minimum standard etching tolerance is ±0.025 mm.

- For thicknesses above this (to a maximum of 2.5mm) the minimum standard etching tolerance is typically ±10% metal thickness.

While traditional metal machining can achieve tighter tolerances, there are limitations. For example, laser technology can achieve accuracy to ±5% of metal thickness; however, this is often limited to a minimum feature size of 0.2 mm. Also, because laser cutting is a “single point” machining method, it is more expensive to produce complex parts with lots of openings such as custom meshes or filters.

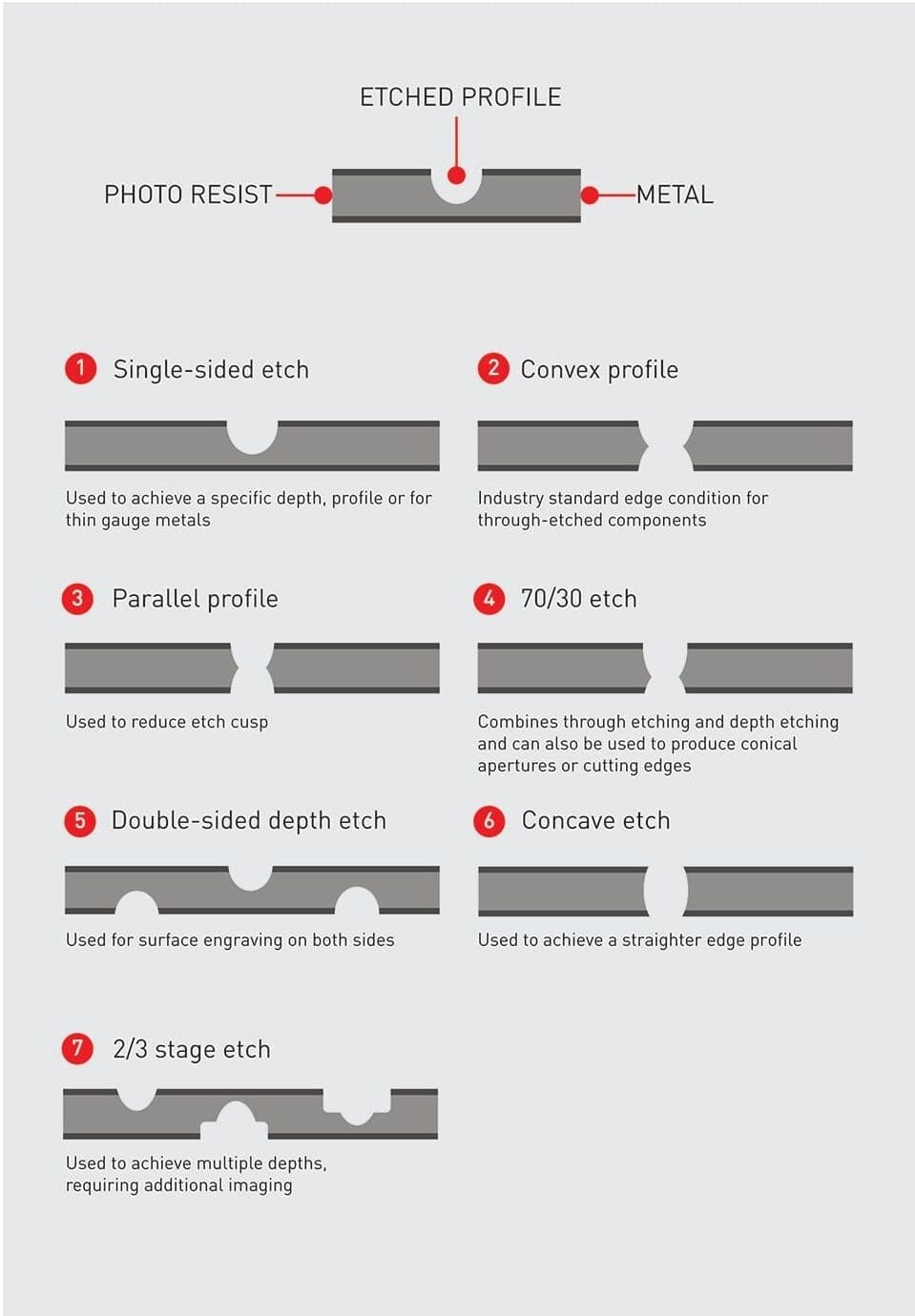

In addition, laser cutting does not offer engraved features that are needed for fluidic devices such as bipolar fuel cell or heat exchanger plates. These are easily attained using the photochemical etching process, which can be accurately controlled to the required depth.

See an overview of etching technical guidelines

Minimum feature sizes of photochemical etching

Chemical etching can achieve a minimum standard feature size of 0.1 mm. Openings below this are possible with development, as is accuracy to ±8% metal thickness.

Burr- and stress-free machining

Stamping is one of the closest machining methods that replicate the accuracy and minimum feature size capabilities of chemical etching. However, using stamping can cause stress and residual burrs on the metal.

In most cases, stamped parts also require costly post-processing, which reduces the viability for short runs. In addition, when processing hard metals, tool wear is an issue with longer runs resulting in additional expense and time-consuming refurbishment often necessary.

As photochemical etching avoids the use of hard tooling, it eliminates distortion and stress, resulting in flat components with a smooth surface and no burrs, as metal is uniformly dissolved until the desired geometries are attained.

For these reasons, numerous spring designers opt for photochemical etching instead of stamping, favouring chemical etching due to its burr- and stress-free characteristics, zero tool wear and rapid supply capabilities.

Unique features at no additional cost

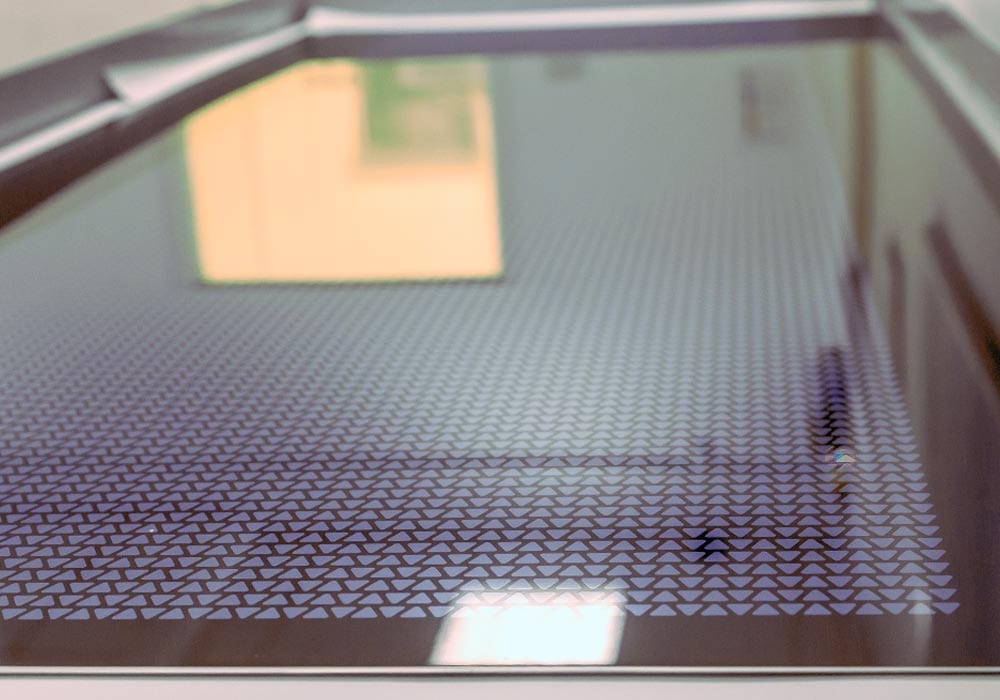

Engineers can design products with distinctive features, thanks to the inherent edge “cusp” controlled by the chemical milling process. This enables the creation of various unique profiles, including sharp cutting edges utilised in medical blades or conical openings for directing fluid flow in filtration meshes.

Low set up costs and design modifications

In sheet metalworking, making parts more complex usually leads to higher costs due to the need for intricate tooling. Costs can also increase when dealing with non-standard materials and specifications, but chemical milling is not affected by these factors.

Etching not only copes well with difficult geometries but also allows enormous flexibility, facilitating the adjustment of designs right up to the point of manufacture thanks to inexpensive digital tooling.

Rapid prototyping

In contrast to alternative metal cutting methods, chemical etching operates on a per-sheet payment basis. This allows the simultaneous processing of components with diverse geometries from a single tool, resulting in significant cost savings during development.

The speed of chemical etching is inherently faster, with tooling typically taking a few hours to produce instead of days or weeks, which explains the widespread adoption of this technology for prototyping.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download