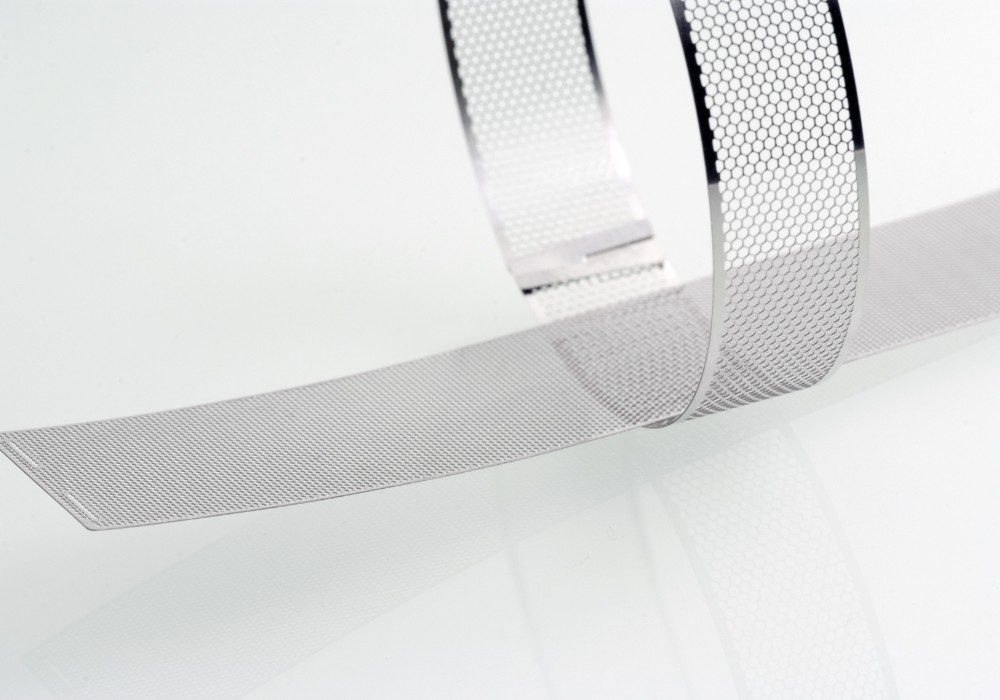

Having problems with stamping or laser cutting? Photo etching may be the answer

With traditional machining technologies, complexity equals cost. The tooling for complex components costs more and non-standard materials, thicknesses and grades are more expensive to process.

The geometric complexity and precision tolerances offered by photo etching make it not just a desirable manufacturing process but in some instances the only technology suitable for extreme environment applications.

The video below shows how photo etching compares with traditional machining technologies:

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download