Metal shims manufacturing processes: Comparing stamping, laser cutting and chemical etching

Precision metal shims may appear as simple parts upon initial inspection, but their role in ensuring the seamless operation of complex machinery is unparalleled in engineering. Meeting precise tolerances and specifications is crucial for these seemingly simple components to deliver high-performance results.

In this post, we explore the various machining techniques used for manufacturing precision metal shims and explore the lesser-known but highly advantageous method of photochemical etching.

Understanding Metal Shims

Custom metal shims are used in a diverse range of industries, including automotive, aerospace, electronics, medical devices and renewable energy. They reduce wear, enhance product lifespan and serve as spacers between mechanical elements, effectively absorbing impacts, minimising ‘play’ or undesired movement and providing protection to material surfaces.

Conventional Metal Shim Manufacturing Processes

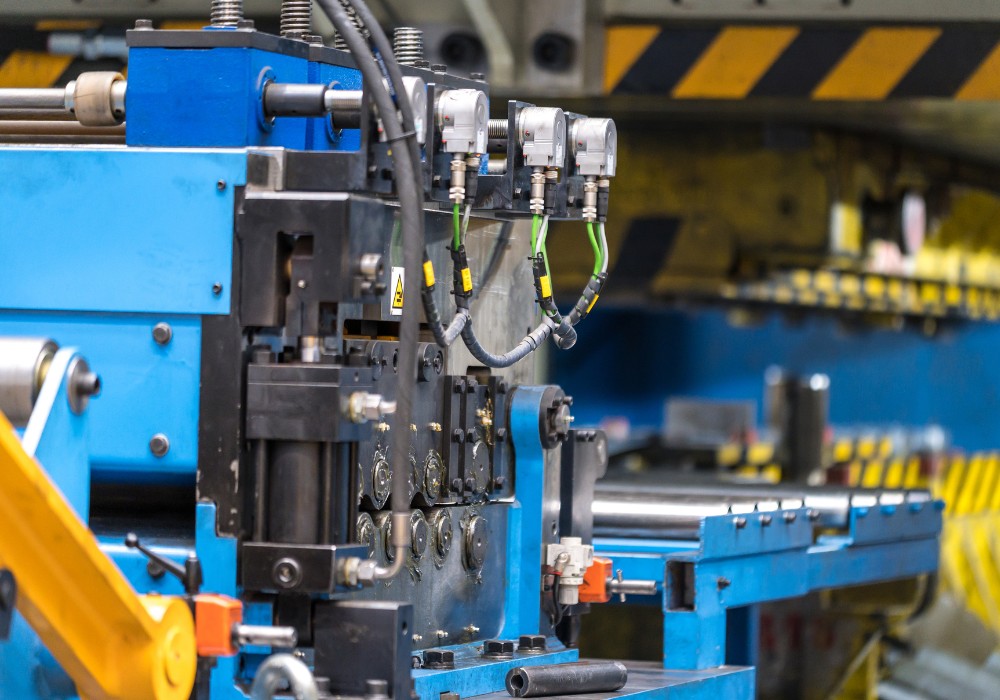

Stamping Metal Shims

Stamping is a commonly used method for producing metal shims. The process involves using a custom die to exert controlled force to cut out and shape the desired shim from a metal sheet, providing speed and efficiency during high-volume production runs and reliable and accurate components.

However, stamping does have limitations, including reduced material versatility, the potential for burrs to form during the process and hard die tooling setup costs which can be uneconomical.

Laser Cutting Metal Shims

Laser cutting is known for its precision and versatility, making it another popular machining method. Challenges occur when dealing with highly reflective metals and intricate designs. Additionally, the high temperatures generated during laser cutting can introduce thermal stress, which can adversely affect the properties of the shim components.

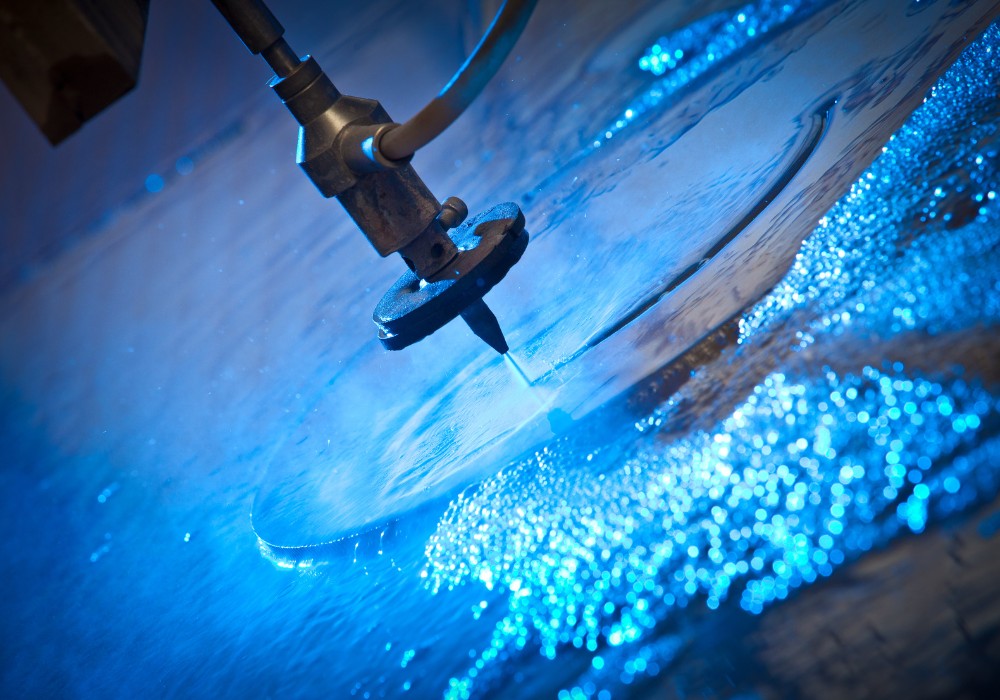

Waterjet Cutting Metal Shims

Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to precisely cut through various materials, offering versatility and speed for simpler designs and prototypes. However, it can lead to issues with component quality and aesthetic appearance due to burr formation and rough textures.

Chemical Etching: The Alternative Approach

Chemical etching is a non-contact, non-thermal subtractive manufacturing process that employs chemical etchants to selectively dissolve material from a metal sheet, creating precise and intricate shims with exceptional accuracy.

Quality Without Compromise

One of the main benefits of implementing chemical etching into your metal shim production process is the elimination of burrs and stress, ensuring optimal performance and a smooth, clean aesthetic finish.

Material Versatility

Photo etching is a versatile process that can work with almost any metal between 0.01mm to 2.5mm thick, regardless of grade or temper. This flexibility enables designers to select the most suitable metal shim material based on its function within an application.

Accuracy and Cost-effectiveness

Chemical etching uses digital photo tools, eliminating the need for costly hard tooling. This not only reduces upfront costs but allows for rapid prototyping and iterative design adjustments, as changes can be made seamlessly in a matter of hours. Moreover, chemical etching can achieve a level of geometric precision of ±0.025mm, ensuring the production of highly precise metal shims.

Conclusion

Chemical etching offers a smarter approach to manufacturing custom metal shims. It not only streamlines production but also overcomes limitations associated with traditional methods. With the flexibility, precision and cost-effectiveness of chemical etching, engineers and designers can unlock new possibilities and produce precision metal shims that excel in any application.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download