Photo etched speaker grilles: A sound approach

Precision Micro’s photo etched speaker grilles enable automotive engineers to add aesthetic and functional advantages to their designs.

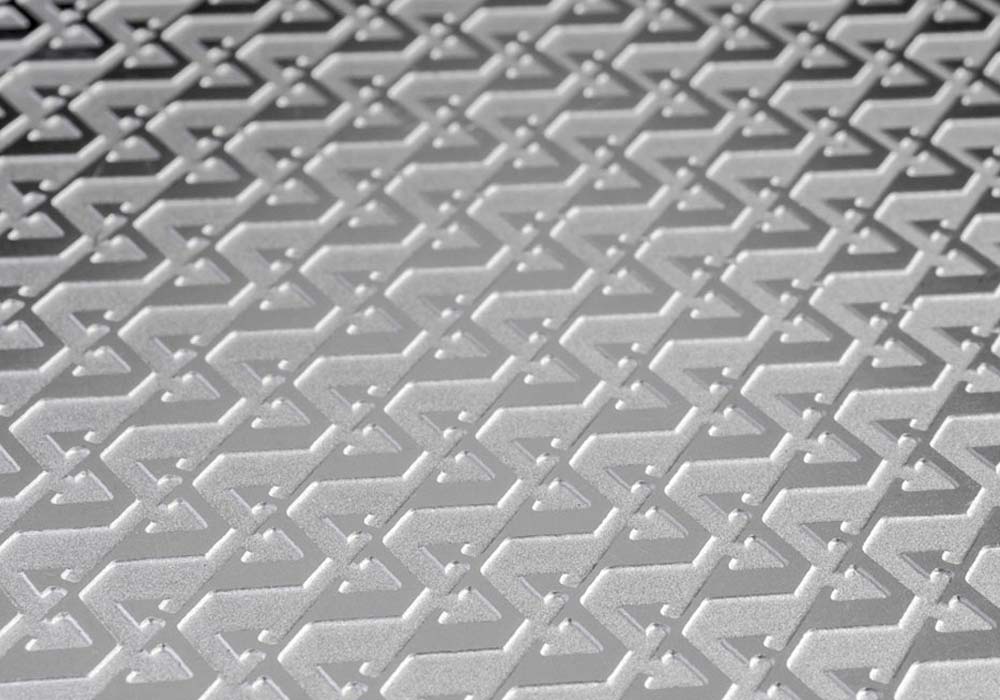

While the use of photo etching is pan-industrial, it is a metal machining technology that is especially at home in the automotive sector, where it has been adopted by many of the leading premium and luxury automotive OEMs due to its ability to produce highly aesthetic complex mesh patterns and high definition surface engraving.

In the manufacture of photo etched speaker grilles, etching allows OEMs to move away from the use of thick woven aluminium wire which was often the go-to material for such applications and adds aesthetic and functional advantages such as facilitating the manufacture of thinner grilles with superior rigidity, higher durability and greater open areas with finer apertures.

No time-consuming and expensive hard steel tooling

Photo etching is unique in the fact that it doesn’t require time-consuming and expensive hard steel tooling. Instead, it uses digital tooling that gives interior trim designers the freedom to experiment without incurring expensive set-up or modification charges as they seek competitive differentiation for their vehicles.

The use of digital tooling means that products can make the transition from prototype to production in a matter of hours

Unlike stamping, etching is both burr and stress-free, and openings and surface engraving are possible to ±0.025mm accuracy. Complexity is almost unlimited, meaning designers can add high definition logos if required and can have openings of any size, shape, and in any position at no extra cost.

Fascias, inlays, dials and tread plates

Custom speaker grilles are just one of the ways that photo etching can give automotive interior design engineers the freedom to explore new opportunities. Precision Micro also works with a number of automotive companies looking to manufacture tactile fascias, steering and gear knob inlays, dials and tread plates.

Dashboard fascias can be manufactured from 0.1mm-1mm thick aluminium, steel, or titanium, etching being used to surface engrave and emboss intricate, blemish-free tactile surfaces – again, with no limit on design complexity. As one of the few suppliers to offer sheets to 600mm x 1500mm in size, Precision Micro can guarantee economic volume supply.

For tread plates, photo etching can incorporate sharp aperture and directional mesh patterns for backlighting, and the plates can be personalised with owners’ names or signatures which is uneconomical when using traditional pressing technologies.

Supply partnerships with leading names

Precision Micro has had a long-standing supply partnership with automotive OEMs, tier-one, and tier-two manufacturers, producing speaker grilles for models including Jaguar XJ, Mercedes C-Class and Rolls-Royce Wraith, to name but a few.

Today, the company is producing millions of photo etched speaker grilles each year and is one of the only suppliers in the world with the etch capacity to cater for current and forecast future demand.

As a technology, photo etching can truly be seen as an innovation driver, as demonstrated by its precision, versatility, scalability and aesthetic qualities, overcoming the constraints that alternative technologies place upon design and manufacturing engineers.

Read more about photo etched speaker grilles and interior trim components

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download