PIONEERING PHOTOCHEMICAL ETCHING SINCE 1962

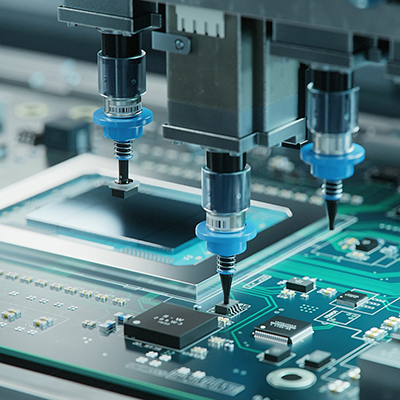

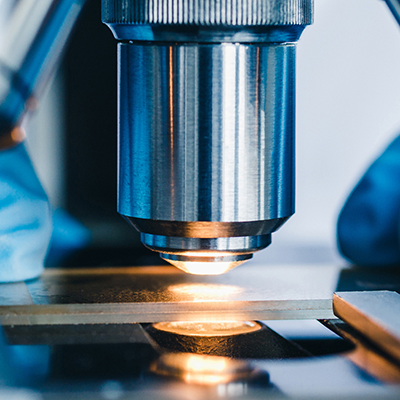

Precision Micro specialises in transforming sheet metals into high-precision components with the flexibility, short lead times and full traceability needed in today’s always-on world.

Our world-class production facility, equipped with state-of-the-art technology and time served engineers, positions us as one of the largest and most respected chemical etching suppliers globally.

Industries Served

Components

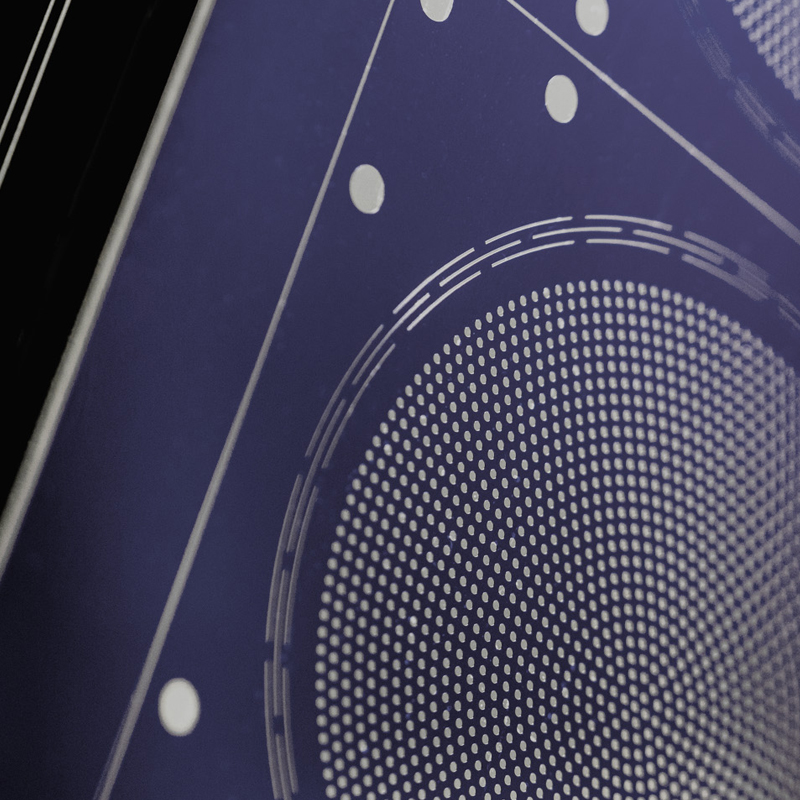

Speaker Grilles

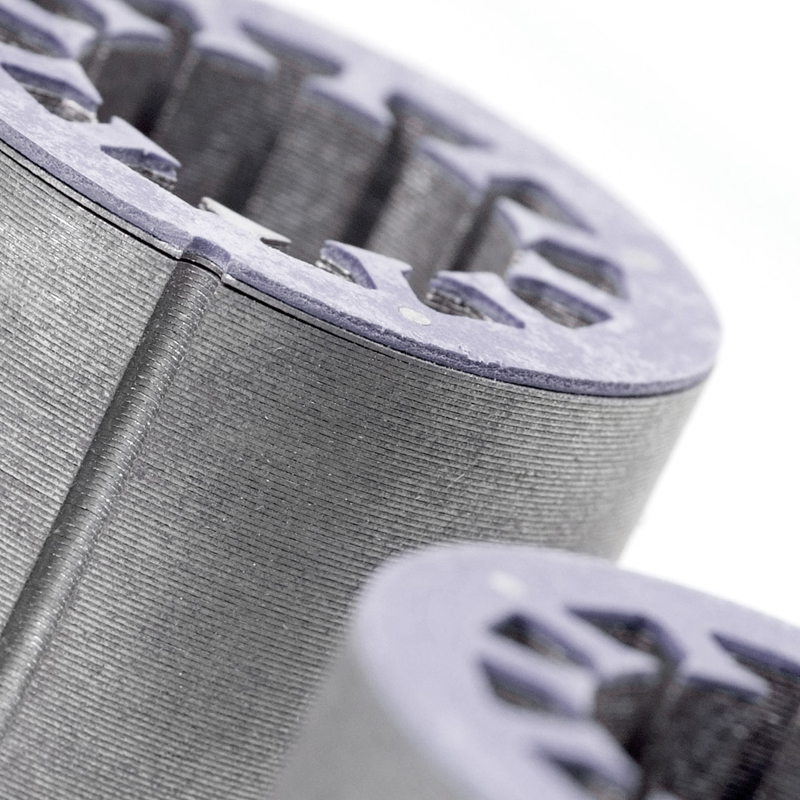

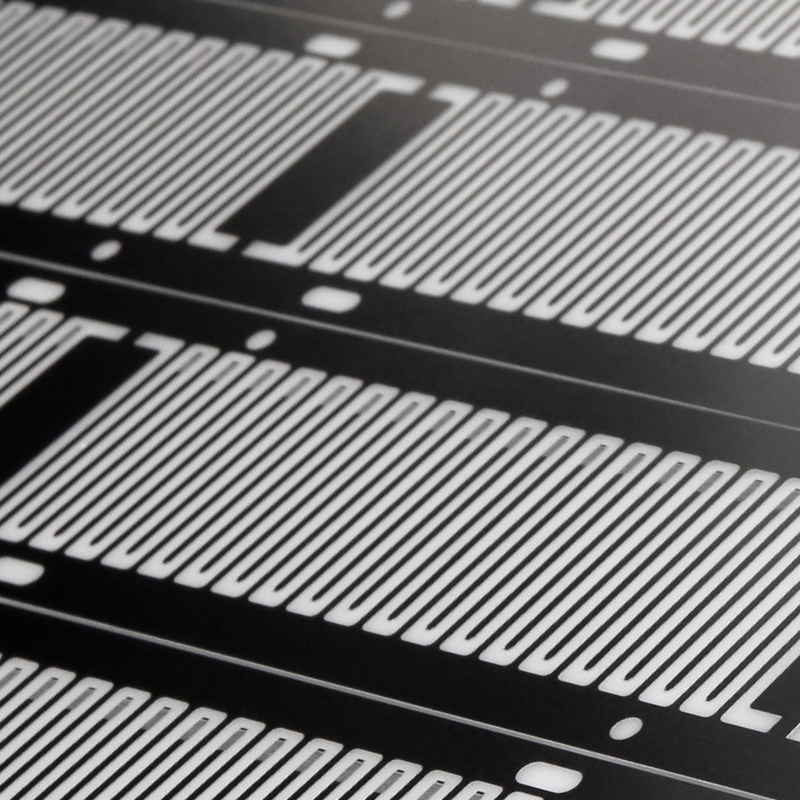

Electric Motor Laminations

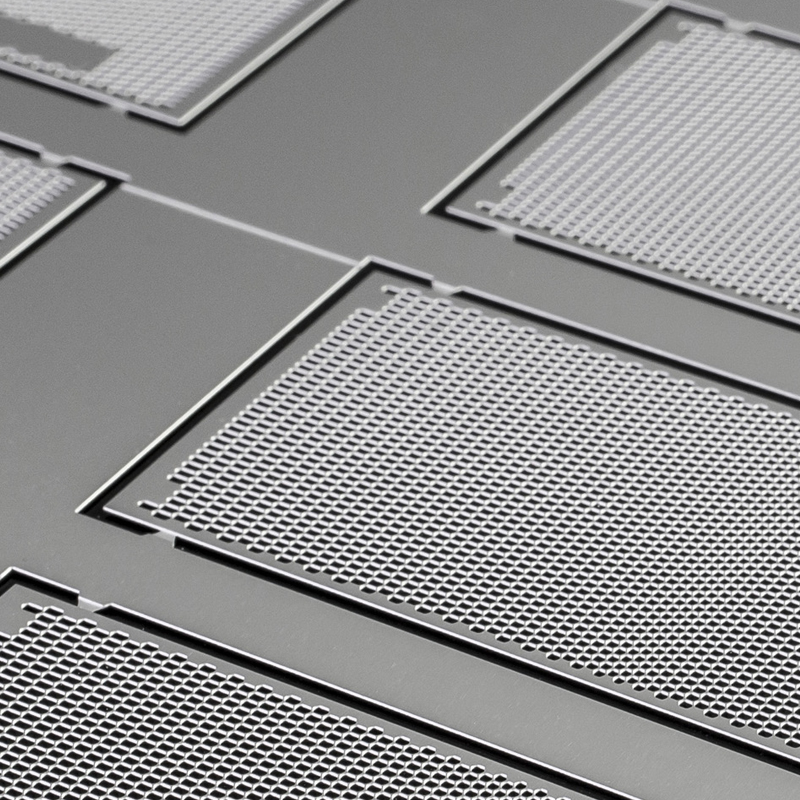

Filters, Screens & Sieves

Custom Metal Shims

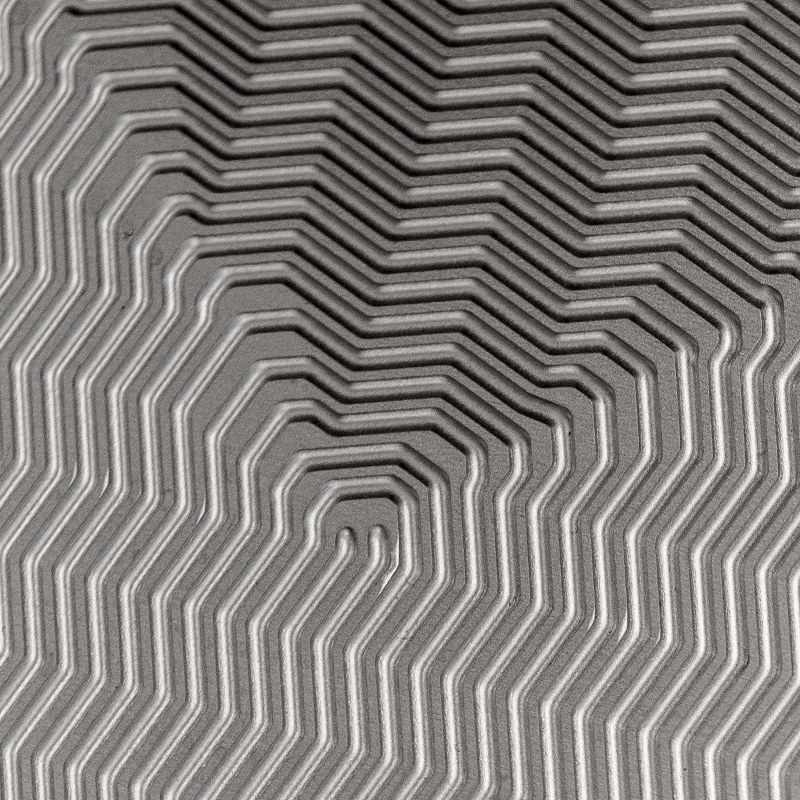

Bipolar Plates

PCB Shielding Cans

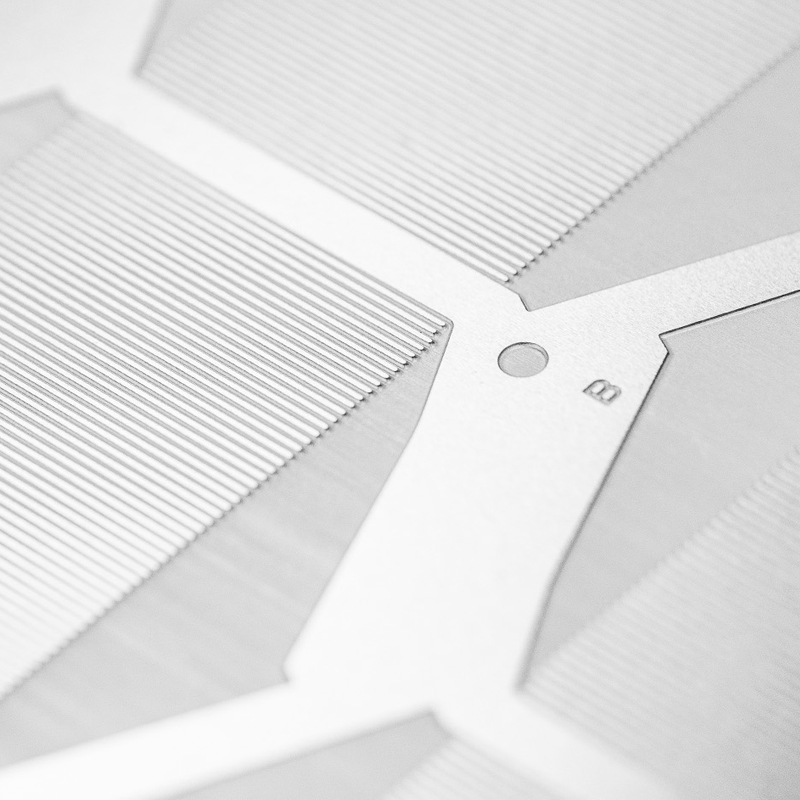

Flat Springs

Printed Circuit Heat Exchangers

Lead Frames

Electrical Connectors

Medical Devices & Instruments

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

DownloadLatest News & Articles

Press Release23.04.2024

Green energy opportunities grow as Precision Micro expands its production facility