Why energy start ups should rethink stamping

Most design engineers have a natural reflex when it comes to making metal components: they turn to stamping, laser cutting or machining. These are the processes they learnt, the ones they see most often in industry. Yet while tried and tested, they can be slow and expensive – particularly for start-ups who need to move quickly. Here, Ben Kitson, head of business development at Precision Micro, explains why etching could be better option for energy start-ups.

The context is familiar. In the race to commercialise cleaner energy, start-ups are working against the clock. Whether it’s hydrogen fuel cells, electrolysers or compact heat exchangers, designs change frequently in the early stages. Prototyping often needs to be repeated multiple times before a product is ready to scale.

Choosing the wrong manufacturing route can add months to development time and tie up scarce capital in costly tooling. That is why an increasing number of innovators are turning to etching.

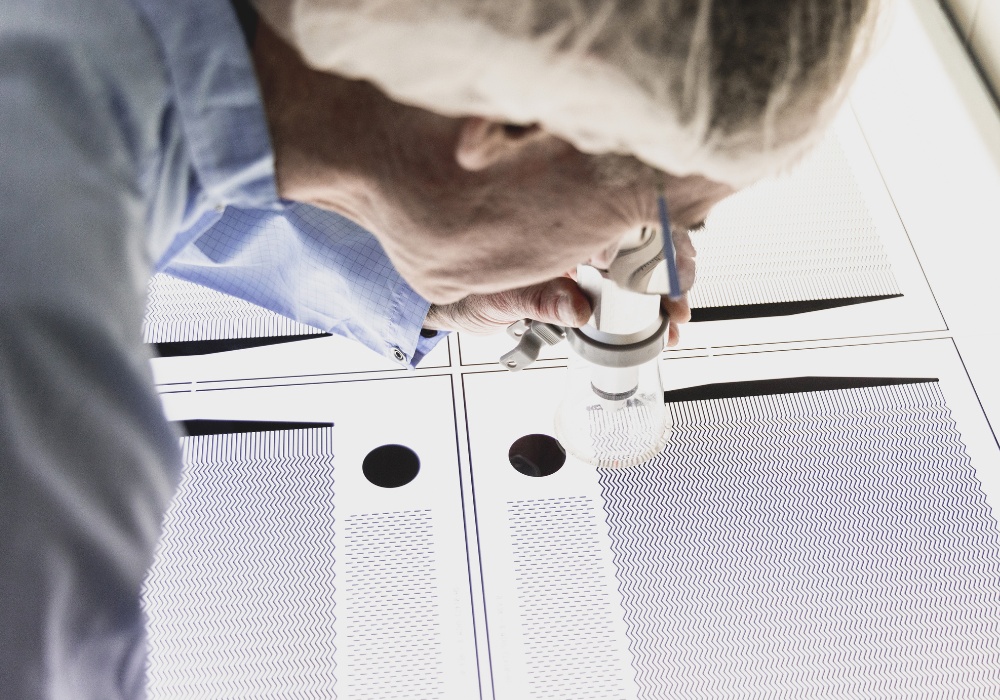

Chemical etching uses controlled chemistry to dissolve patterns directly into metal sheets. Because it uses photographic masks created directly from CAD files, rather than physical moulds or dies, design changes can be made at negligible cost. More importantly, parts can be produced in days – sometimes even in 24 hours – compared with the weeks or months often associated with stamping tools.

For start-ups, this speed and flexibility can be transformative. A design engineer can test a component, refine it, and have an updated version in hand within a fortnight. That ability to iterate quickly without prohibitive expense helps companies get products investor-ready and into pilot projects faster.

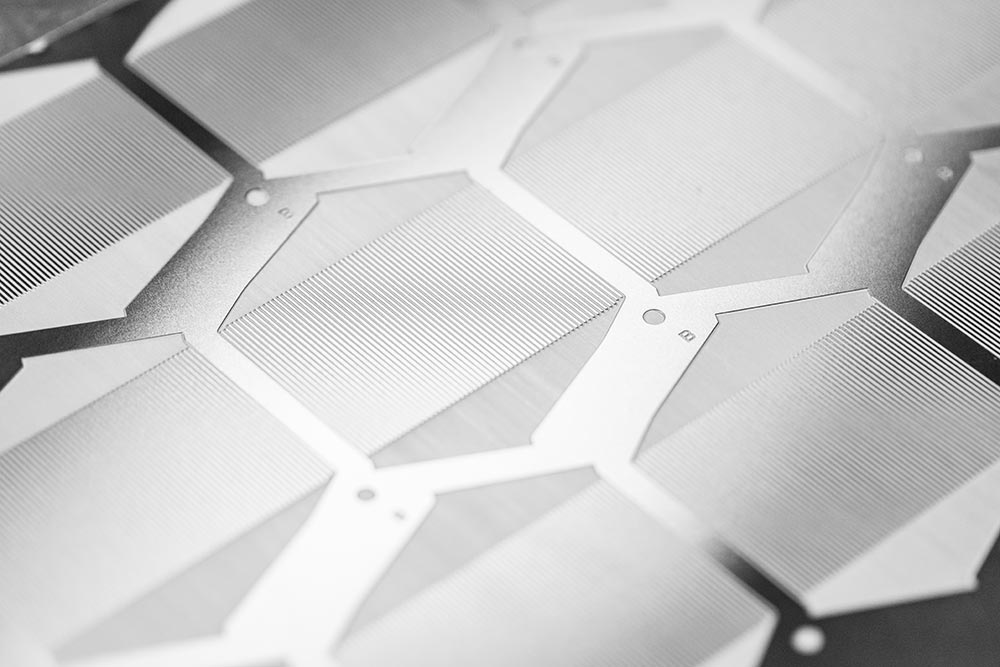

Etching is also well suited to the types of components energy start-ups need. Bipolar plates for hydrogen fuel cells, flow plates in electrolysers and compact printed circuit heat exchangers all require intricate designs with lots of fine channels and holes.

These are challenging to machine or stamp but are routine for etching, which produces flat, burr-free, stress-free parts. Because the process does not introduce mechanical stress or heat damage, the resulting components maintain their material integrity, which is vital when working with demanding alloys or when long-term reliability is essential.

These properties make etching not just a convenient option but an enabler of designs that might otherwise be impractical. Intricate fluid channels, tight tolerances and complex geometries can all be achieved without cost penalties. For start-ups trying to prove performance and secure investment, this means they can focus on optimising design rather than compromising to suit a process.

A case in point is a US company developing alkaline exchange membranes to lower the cost of green hydrogen. Their breakthrough materials can reduce stack costs by up to 80 per cent, helping to cut overall hydrogen costs by a third.

Precision Micro worked with its customer to adapt flow plate designs originally drawn for stamping, making them suitable for etching instead. By avoiding the need for expensive hard tooling, they could prototype quickly and economically – a game-changer for a start-up intent on accelerating commercialisation.

From prototype to scale-up

While some companies transition to stamping once volumes justify the investment, many continue with etching if designs are too intricate or performance-critical. In practice, etching often carries products through the crucial development and early production phases, providing the agility needed before higher-volume methods are viable.

Beyond hydrogen, etched parts already underpin applications in aerospace heat exchangers, electric vehicle busbars and stainless-steel meshes for filtration. The same qualities that make it attractive to start-ups – speed, flexibility and precision – are valued across these sectors.

Ultimately, stamping and machining will always have a place in manufacturing, but for start-ups who cannot afford long delays or expensive missteps, chemical etching provides a fast, flexible and cost-effective alternative. It’s regrettable that many design engineers would not consider it, simply because they are unaware of it. However, in the push for cleaner energy, the companies that embrace enabling technologies like etching early are the ones most likely to cross the finish line first.

To find out if chemical etching is the right solution for your application, you can upload your design here or contact Ben directly on ben.kitson@precisionmicro.com

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download