Which metals are suitable for chemical etching?

Chemical etching has numerous advantages over traditional sheet metalworking processes, one of which is its applicability to the widest range of metals and alloys — even those that are difficult to machine.

In this article, we look at some of the typical metals suitable for chemical etching.

How to etch metal

Before we get into the different metals that can be etched, the process should be quickly discussed so you can understand why we choose to chemically etch metal in the first place.

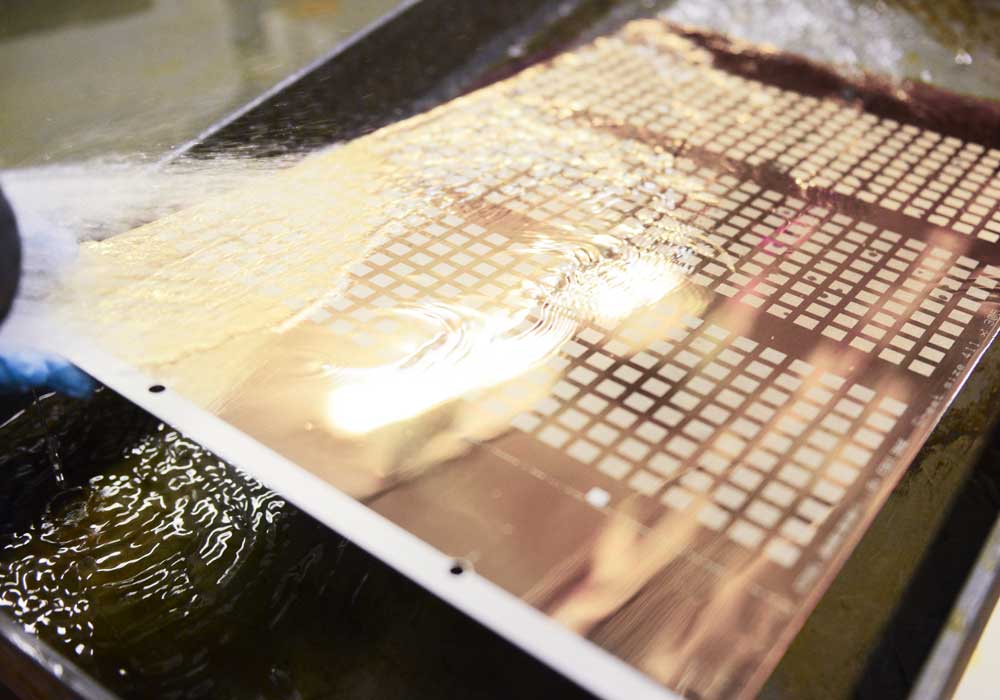

Etching metal is done using chemicals in modern manufacturing because of its high accuracy and low failure rate. The chemical etching process works via a component design being ‘printed’ onto photoresists, which is laminated onto your chosen metal. The excess photoresist is then removed and the exposed metal is etched away.

Chemical etching metal: Materials overview

Virtually any metal can be chemically etched, but as with most metal machining processes some are easier to etch than others.

As demand from industry often focuses on metals that have attractive attributes, it is with these metals that our efforts are focused to ensure our processes are developed in line with customers’ market demands.

Etching titanium and its alloys

Titanium is lightweight, strong and has excellent fatigue performance, as well as offering high resistance in aggressive environments. These favourable properties, however, prove to be a problem when machining.

Titanium’s high strength, low thermal conductivity and chemical reactivity with traditional tool materials (at elevated temperatures) significantly reduces tool life when machining.

Its relatively low Young’s modulus leads to spring-back and chatter, causing poor surface quality on the finished product.

In addition, during turning and drilling, long continuous chips are produced, which can lead to entanglement with the cutting tool, making automated machining challenging.

The use of chemical etching overcomes many of these issues, but even etching titanium is difficult as the metal forms a protective oxide coating when exposed to air meaning it cannot be etched with standard etch chemistries.

To overcome this, specialist equipment and process chemistry, typically hydrofluoric acid, is required to produce etched parts comparable in quality to those produced in more conventional materials.

Aluminium etching

Aluminium exhibits many of the attributes of titanium — notably its high strength to weight ratio and natural corrosion resistance — but whereas titanium is stronger and more corrosion resistant than aluminium, aluminium has a better fatigue limit, which makes it ideally suited to aerospace applications.

When conventionally machining aluminium, there are several issues that can compromise the quality of cut, including heat reflectivity and the coating of presswork dies.

For many suppliers, aluminium is also difficult to etch effectively as the heat energy it releases during etching often results in a rough, granular edge.

As with titanium, a proprietary method for etching aluminium is required to ensure edge quality comparable to stainless steel.

Etching steel and stainless steels

While stainless steel is less troublesome to etch, it still requires the application of experience and significant investment in processing technologies to optimise customer outcomes, especially in volume manufacture.

The stainless steel etching process takes stainless steel laminated with a photoresist mask printed with a CAD image of the component, which is then selectively etched with ferric chloride, a safe to use, recyclable etchant chemistry.

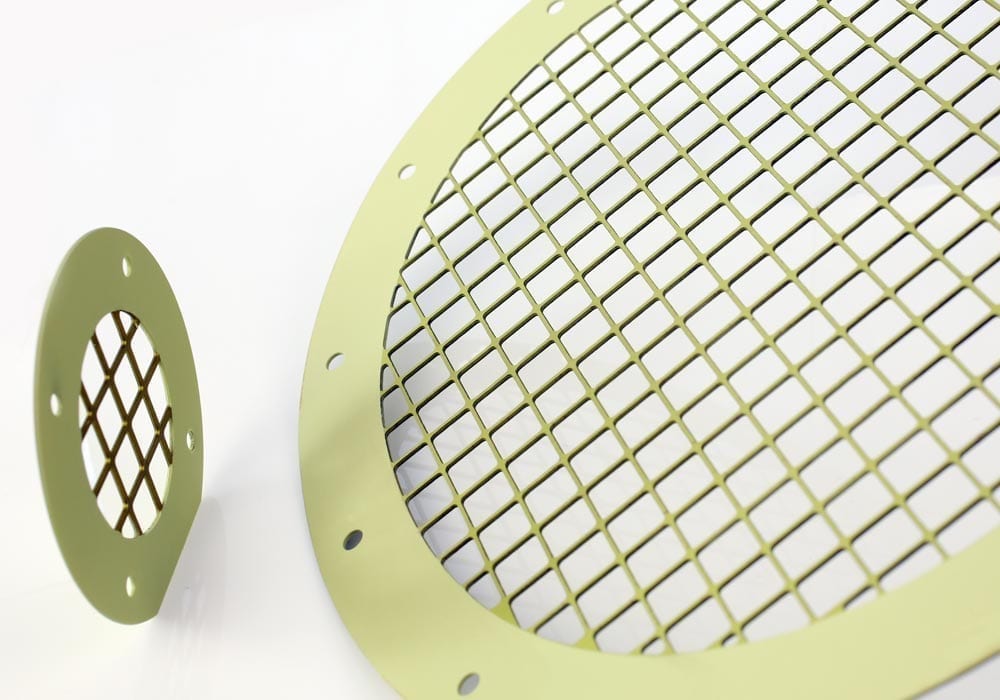

Due to its versatility and range of available grades, stainless steel is used in a wide variety of applications, all of which benefit from burr and stress-free features and no cost penalty for component complexity.

Copper and copper alloy etching

As a relatively soft metal, copper etches quickly in standard etch chemistries, whereas contact machining processes can distort the metal, altering its properties.

Copper and its alloys are highly conductive, durable, ductile and malleable, meaning they are well suited to 2-D and 3-D electronics components.

Nickel and nickel alloy etching

Nickel exhibits high resistance to heat and corrosion, though again etching is relatively straightforward with standard etch chemistries.

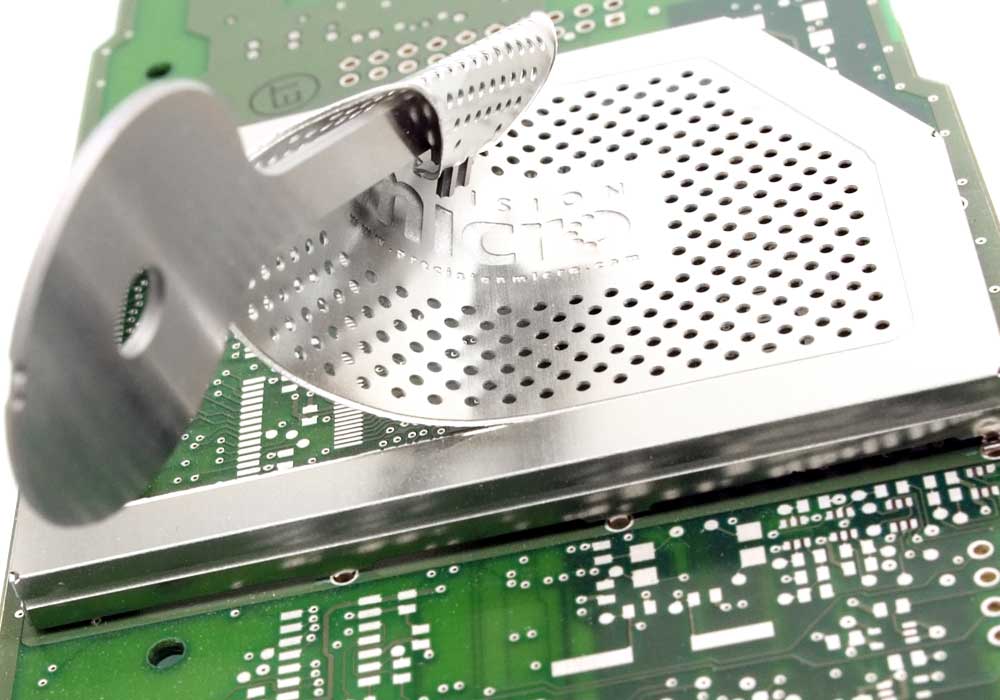

Nickel silver is the most cost-effective material choice for electronics shielding as it can be soldered, will not oxidise and requires no additional plating.

Digital photo-tooling offsets expensive press tools, and bend lines can be incorporated so EMI/RFI shielding components can be formed by hand.

Inconel

Inconel is a high-temperature nickel-based super-alloy that offers superior heat resistance and exhibits excellent resistance to corrosion, pressure and oxidation.

It is these properties that make it difficult to machine – and indeed etch.

Precision Micro has developed a process for chemical etching Inconel, specialising in microfluidic plates with complex etched channels such as bipolar fuel cell plates.

Why should I choose Precision Micro as my chemical etching supplier?

Success in etching any metal is down to the experience and skill of your chosen chemical etching partner.

Precision Micro has almost 60 years of metal etching experience, operating Europe’s largest sheet metal etching plant.

Continual investment in the research and development of chemical etchants and process parameters means that today, even the most challenging metals can be processed in volume and to exacting standards in terms of tolerance and accuracy.

All of this is underpinned by robust quality management systems, with our etching process accredited to ISO 9100, IATF 16949, ISO 14001 and AS 9100.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download