Three reasons to trust photochemical etching for your next metal component prototype

Most design engineers trust “traditional” metal machining methods. However, for many industries such as automotive, aerospace, electronics and healthcare, challenges can arise during the machining of complex precision components.

Laser cutting and stamping are two of the most common ways to shape and cut detailed design features, but while dependable, they can also create problems during the process.

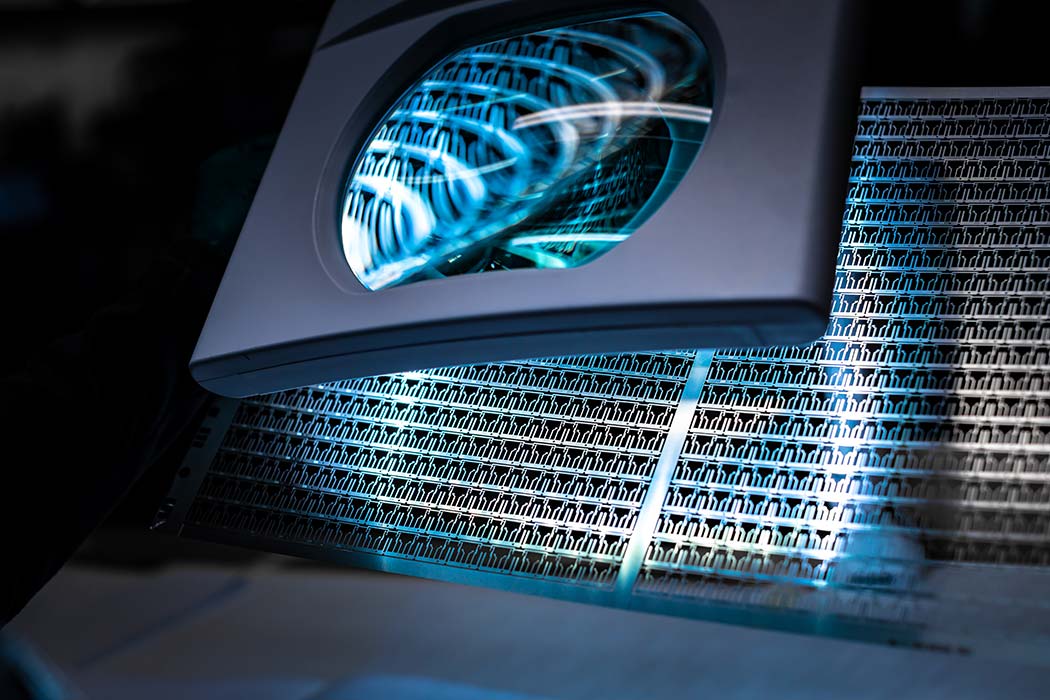

There is a solution: photochemical etching, a metal machining process that uses chemical etchants to create complex and highly accurate precision components.

While it’s easy to define, it’s important to know the main reasons for choosing photochemical etching in the production process.

1. Low Barrier to Entry

Photochemical etching offers you the chance to prototype from the widest range of materials, including those deemed difficult to work with, with little to no setup costs.

Conventional machining, laser cutting and stamping can face various issues when machining certain metals. With the parameters and limitations of metals like aluminium, titanium and Inconel, it is not always possible to create truly precision-engineered components.

Photochemical etching, by comparison, presents a more economical and efficient way to produce custom parts with complex designs and strict tolerances. This is possible by combining sheet metal with a CAD printed photoresist mask of the required components, with the chemical etching offering a less intrusive and more delicate process for creating quality, intricate components.

The value of photochemical etching is truly found through the inexpensive and easily reworked photo-tools that ensure high accuracy and repeatability in production, perfect for providing OEMs with the critical components they need in short lead times for a great price.

2. Improved Cut Quality

Precision etched components are vital elements of many applications and even the slightest blemish can create significant disparities in the quality of the final product. Traditional processing methods such as laser cutting and stamping can cause those issues.

Thermal and cutting edge stresses are familiar factors that affect the quality of the components produced. Thermal stress results from heat generated during the metalworking process, this can not only cause metal to expand and contract but under extreme heat, it can also alter the properties of the materials used. This is very important to be aware of in components where even the slightest imperfections can affect their quality and effectiveness.

Cutting edge stress is a result of stamping, it causes a physical stretch on the cutting edge which can have a detrimental effect on the flatness of the blank, especially when high levels of precision are required.

Another common issue is burring, which is caused by heat generation of physical impact that compromises the accuracy and dimensions of the most precise engineered components. Burring is so common and widely accepted that post-machining methods such as linishing and barrelling are part of the production process to minimise the presence of burring.

Photochemical etching eliminates potential stress as there’s no heat or physical impact on the etching process. Similarly, with no impact force or harsh cutting, there are no burred edges. Only by using photochemical etching you can eliminate the uncertainty and guarantee quality and repeatability across all your components.

3. Reduced Lead Times

Uncertainty can hugely affect supply chain chains. In manufacturing, that instability is caused by uncertain lead times. As we’ve already discussed, burring and stresses cause issues with production meaning more processes are required to deliver a quality final product.

Issues on the product line create a domino effect as this leads to increased inventory and tooling costs while delivering an inconsistent service to customers.

Photochemical etching can simplify this process as it eliminates stress and burring, allowing for products to be delivered to an exceptional standard in just a few days – rather than weeks or months. It also reduces tooling costs, as the need to correct the issues caused by traditional methods is eliminated, providing certainty right down your supply chain.

While chemical etching provides simplicity, the process also allows even the most complex of parts to be created, opening up more avenues for you and your clients.

It’s clear that photochemical etching should be the method of choice for metal machining. With reduced lead times, fewer costs and the ability to precisely cut even the most difficult metals in larger quantities, it’s time to implement alternative methods to produce components of the highest quality.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download