Cost-effective precision metal manufacturing

First featured in MEPCA Magazine, April 2019

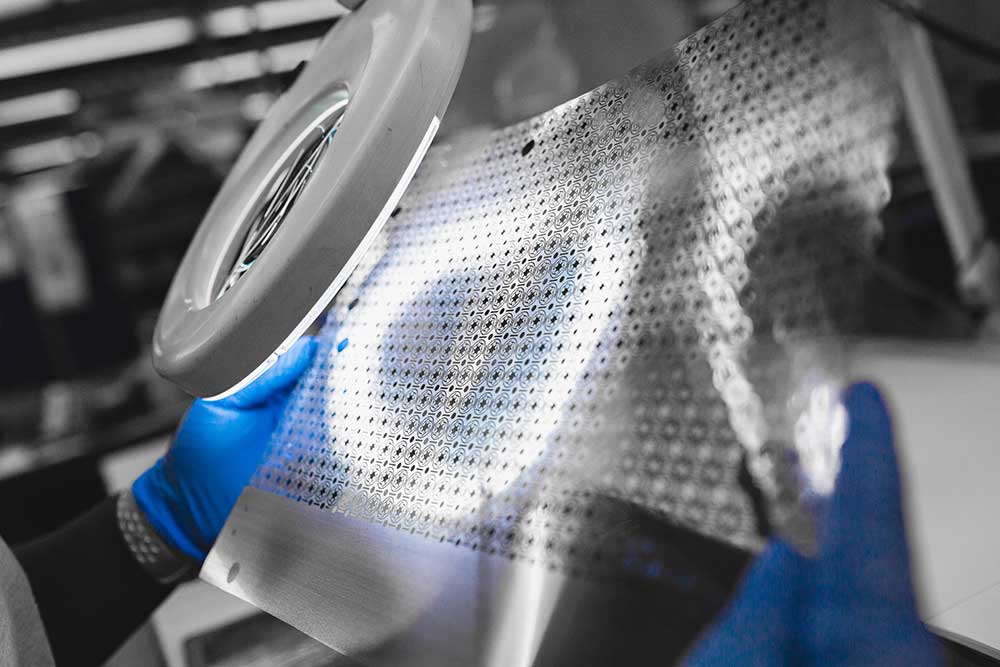

Demand from industry today is for a reliable and robust metal processing technology. Photo etching specialist, Precision Micro, explains how the techniques they use can help drive innovation by opening up timely, cost-effective complexity in manufacturing.

When benchmarking technologies that can produce precision metal parts, viable alternatives include photo etching, stamping, punching and laser cutting. When looking at processing technologies that can mass produce smaller, thinner and more complex components at volume, this list is shortened, the options benchmarked being photo etching and stamping.

Benchmarking photo chemical etching

Photo etching produces stress-free, flat components by employing selective etching through a photoresist mask, and when compared with conventional production processes such as stamping, it has many inherent advantages.

Among these are the ability to produce parts without degrading material properties, the fact that there is almost no limit to part complexity, and the ability to process a huge range of metals and alloys.

Conventional processing technologies suffer from several drawbacks, including the degradation of the material being processed due to high impact in the case of stamping or punching, or in the case of laser cutting the use of intense heat. However, another differentiator is in the area of tooling.

The tooling for photo etching is digital. This means that large quantities of products can be reproduced with absolutely zero tool wear, ensuring that the first and millionth part produced are precisely the same.

Also, as the tooling for photo etching is virtual, it can be adapted and changed extremely quickly and economically, making it ideal for anything from prototype to high volume production runs. This also allows for design optimisation without a financial penalty and helps to ensure a low-risk entry strategy.

Turnaround time using photo-tools is about 90% less than that for stamped parts, stamping requiring substantial investment in mould fabrication which is not only costly but can take from 6-10 months to complete – compared with a few hours for etching.

The economy and adaptability of the tooling for photo etching is a significant stimulus for design freedom and also the ability to produce geometrically complicated products. As the cost of creating prototypes is so low there is no barrier to entry, with complex designs being produced in days and design iterations in hours.

Manufacturing the impossible

Photo etching in this way stimulates innovation and removes constraints on design engineers as it allows for the manufacture of parts considered impossible using traditional manufacturing processes. Indeed, in many industrial applications today, geometric complexity and the requirement for extremely exacting tolerances and precision mean that photo etching is not just a potentially desirable manufacturing process, but is, in fact, the only technology able to make certain products.

When stamping, part complexity often adds cost, whether in low, medium or high-volume applications. The complexity of a product means the necessity for a complex mould tool, and complex tooling means increased costs, increased potential for tool failure and increased lead-times for satisfactory completion. Photo etching is unaffected by the level of tool complexity, and the intricacy of a part’s geometry makes no difference in terms of costs or lead-time and therefore the complexity of the digital tooling.

Photo etching can also produce finer detail than is possible with stamping, and all with minimal if any degradation and deformation of the metal being processed and little to no likelihood of burrs or defects. Failure rates are also minute, and unlike in the stamping process, every part produced is absolutely flat, which in some applications is vital.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download