Stainless steel etching process: How does stainless steel etching work?

The stainless steel etching process produces precision components by selectively removing metal through a photoresist mask.

When compared with conventional sheet metal working techniques has many inherent advantages, including:

- The ability to produce parts without degrading material properties – no force or heat is used during processing

- Almost limitless part complexity with component features machined simultaneously using etchant chemistries

What is stainless steel etching and how does it work?

Stainless steel etching is a metal etching process that utilises corrosive metals to etch complex and precise components from stainless steel. This process is favoured in modern metal machining due to its high precision and low failure rate.

The stainless steel etching process starts with metal laminated with a light-sensitive photoresist which is exposed to UV light to transfer the CAD image of the component. The areas of unexposed photoresist are removed (developed), then sprayed with etchant chemistry to accurately remove the unprotected stainless steel. The remaining photoresist is removed (stripped) to reveal the final etched component.

The tooling for stainless steel etching is digital, so there is no need to start cutting expensive and difficult to adapt steel moulds. This means that large quantities of products can be reproduced with absolutely zero tool wear, ensuring that the first and millionth part produced is exactly the same.

In addition, digital tooling can be adapted and changed extremely quickly and economically, often within an hour, making it ideally suited to both prototype and high volume production runs.

This allows for “risk-free” design optimisation without financial penalty. Turnaround time is estimated to be 90% quicker than for stamped parts, stamping also requiring substantial upfront investment in mould fabrication.

Chemical etching opens the door for innovation and pushes back many of the barriers seen with traditional sheet metalworking

The economy and adaptability of photo-etch tooling is a key stimulus to design freedom, along with its ability to produce complicated products. As the cost of creating prototypes is low there is no barrier to entry, and complex designs can be produced in a matter of days.

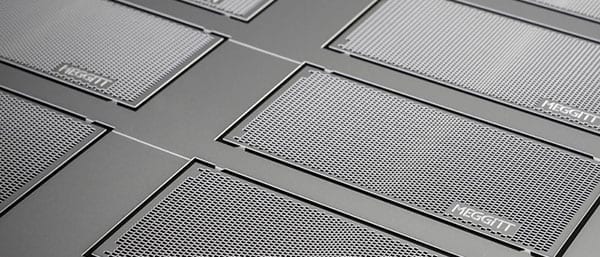

Etched stainless steel components

The stainless steel etching process is suited to pretty much any metal component between 0.01mm and 1.5mm in thickness.

Below are some examples of products where stainless steel etching really adds value.

Meshes, filters and sieves

Unlike conventional machining technologies, chemical etching offers greater levels of complexity when producing thin, precision steel meshes, filters and sieves.

With metal removed simultaneously, multiple aperture geometries can be incorporated without incurring high tool or processing costs. Where punch-perforated sheets are prone to distortion, photo-etched mesh is burr and stress-free with zero material degradation.

A 150-micron thick precision stainless steel mesh used in radiation detection devices is etched by Precision Micro to precision tolerances (below the standard ±10% material thickness) and features a critical honeycomb-shaped mesh array.

Given the mesh is 600mm x 600mm in size, stamping was seen to be uneconomical due to the investment required in press tooling.

Laser cutting could not achieve the required tolerances over such a large surface area and produced undesirable burring around each mesh opening.

Etching does not mar the surface of steel, enabling a highly aesthetic finish

Etching stainless steel does not alter the surface finish of the material. There is zero metal-to-metal contact or heat source used which can mar the surface, offering a highly aesthetic finish.

Automotive speaker grilles with complex hole arrays and surface engraving are supplied by Precision Micro to automotive OEMs in quantities of multiple millions each year. The tooling required to produce the grilles is too complicated for stamping and the mesh pattern is too complex to laser cut.

Read more about etched meshes, filters and sieves

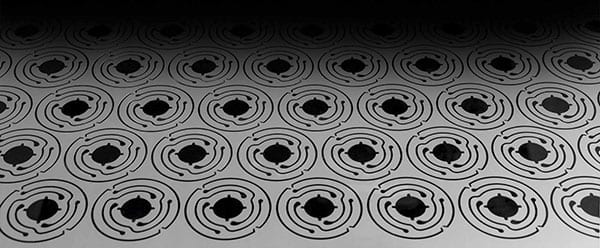

Flexure springs and diaphragms

Often used in safety-critical or extreme environment applications, such as ABS braking systems, medical biosensors or fuel injection, etched flexures have the ability to “flex” millions of times faultlessly as etching does not alter the fatigue strength of the steel.

Environments rarely come more extreme than space and this is why Thales Cryogenics, a leading manufacturer of specialised cryogenic equipment, partnered with Precision Micro for the manufacture of stainless steel flexures used in its satellite cryogenic cooler.

Initially, Thales considered wire EDM for its flexures before turning to chemical etching, but the process would have left small burrs and recast layers on the parts which would compromise spring performance.

Chemical etching eliminated potential fracture sites in the material grain, producing flexures free from burrs and recast layers, ensuring a long product life and higher reliability.

Read more about etched flexure springs

Fuel cell bipolar plates, cooling plates and fluidic devices

Stainless steel grades with increased levels of chromium are well suited to fluidic devices used for liquid-to-liquid or liquid-to-gas heat exchangers, fuel cells and cooling plates, as they offer higher levels of corrosion resistance.

The complex grooves machined into the surface of these plates, which are subsequently stacked and bonded to create captive channels, are well suited to chemical etching as they can be machined onto both sides in a single process.

Whilst CNC machining and stamping can be used to machine and profile these channels, they can compromise flatness and introduce stresses and burrs. Presswork tooling can also be slow and uneconomical to produce, slowing down and adding cost to development timelines.

Read more about bipolar fuel cell plates

Summary

Steel and stainless steels exhibit an array of characteristics that make them ideally suited for numerous pan-industrial applications.

The etching process offers manufacturers significant advantages when producing complex and safety-critical stainless steel components.

These advantages include:

- No expensive hard tooling

- Speedy ramp up from prototype to production

- Almost unlimited part complexity

- Burr- and stress-free component features

- Metal properties unaffected

- Appropriate for all grades, offering accuracy to ±0.025 mm

- Lead times measured in a few days, not weeks or months

The versatility of stainless steel etching, coupled with Precision Micro’s 60 years of experience, makes it a compelling option for the manufacture of stainless steel components across numerous exacting applications.

It can also stimulate innovation, removing obstacles inherent in traditional sheet metalworking technologies.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download