Reducing cost, risk and uncertainty in the supply of precision metal components

In an ideal world, all manufacturers would want the on-time delivery of high-quality components at the lowest possible cost.

It is well-known that these three pillars – cost, quality and speed – are difficult to achieve together. Something almost always has to give. In the case of precision components, this is especially so.

Playing often mission-critical roles in equipment, including in automotive, aerospace and medical applications, the overriding consideration is quality and performance, neither of which can be compromised.

Manufacturers, therefore, have come to accept that quality takes time and comes at a price, and while they build these factors into their production schedule and pricing models, they inevitably still experience inconsistency and supply issues.

But in terms of sheet metalworking at least, there is a way to find a more satisfactory balance to the cost, quality and speed equation.

Let’s consider the process, from R&D all the way through to production and supply.

First, there’s the question of designing and creating a prototype to ensure the correct tolerances and that the component is fit for purpose. This involves tooling and a degree of trial and error, potentially adding time and cost to the process, especially if the chosen material behaves in unexpected ways.

As every metal has distinctive qualities, and every design is unique, this is not uncommon. For example, aluminium, a soft metal, and titanium, a hard one, are both known to present specific challenges which can be costly to resolve.

Mechanical equipment including stamping and water jetting can shear, crush or damage metal edges

Then there’s the actual cutting itself. Mechanical equipment including stamping and water jetting can shear, crush or damage metal edges. Laser cutting uses heat which can also affect the metal.

While these issues may be minimal and can be easily resolved, they nonetheless add another layer of complication. Burring, a feature of metal stamping, presents a similarly common challenge, calling for barrelling, linishing or electromechanical intervention to achieve the desired quality.

At every step of the process, there are potential issues which can create additional cost, delays and lead-time uncertainty, any of which is problematic.

Reducing complexity with photochemical etching

The root cause of this uncertainty is complexity, which usually translates into cost. The easiest way to combat this is through simplicity – such as that presented through photochemical etching.

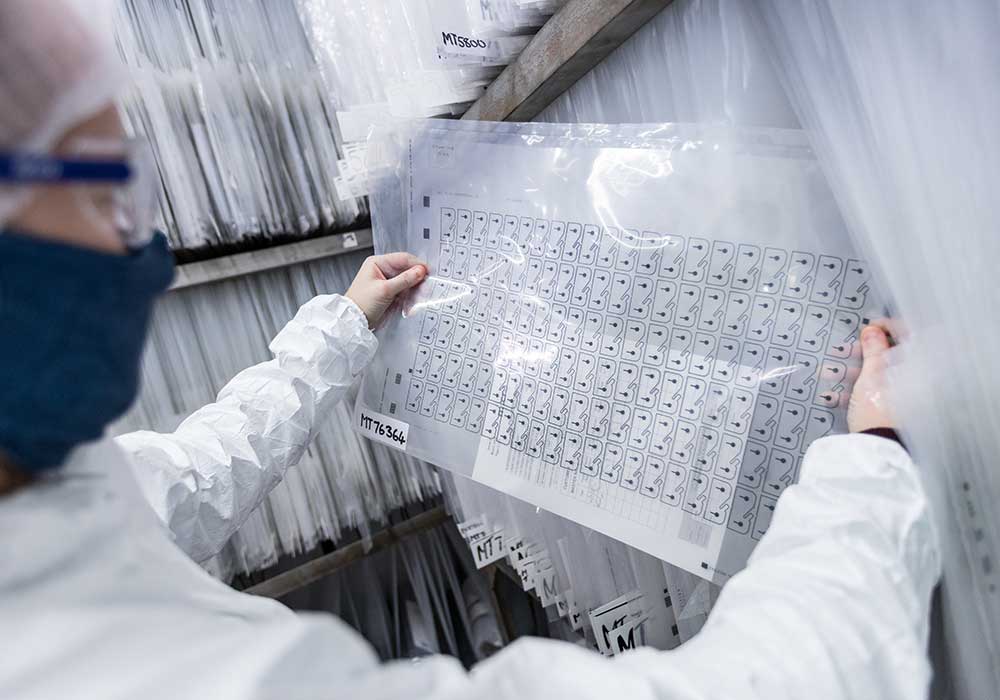

More commonly referred to as chemical etching or photo etching, it’s a ‘subtractive machining process’ where components are printed on specially coated metals using UV light before being selectively etched from the sheets. It has similarities with printing, except in 3D.

Capable of producing highly complex components, photochemical etching can be used on virtually any metal (with a thickness up to 1.5mm), and on sheets up to 1500mm in length.

Offering unlimited geometric customisation and infinitely repeatable accuracy, it’s perfectly suited to the speedy production of even the most intricate designs and is widely used across the industry, even for the most extreme applications.

While the technology might be complex, however, the process itself is streamlined, resulting in a highly cost-effective solution.

Fast, flexible prototyping in days

Digital tooling reduces the costs and time associated with the physical process. Similarly, during prototyping, engineers pay by the sheet of parts, minimising expenditure. And as all component features are etched at the same time – without burring – there’s no further cost for additional processes.

Batches of components can be processed from a single tool in one production run. As a consequence of all this, timeframes can be telescoped from weeks and even months into a matter of days – and sometimes even hours.

Conclusion

While other methods of metalworking – such as stamping, punching and laser and water-jet cutting – are quite capable of delivering a high-quality end-product, the key question is how well they stack up against the cost, quality and speed model. The answer is less well than photochemical etching.

By introducing simplicity into the process, chemical etching enables the cost-effective delivery of precision components, reducing risk and uncertainty throughout the supply chain.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download