A guide to photochemical machining: Precision parts made simple

Photochemical machining (PCM), also known as photochemical etching, is a manufacturing process that is widely used in various industries to produce high-precision metal parts with complex geometries.

PCM combines chemical etching and photographic techniques to produce precise parts that would be difficult or impossible to manufacture using traditional mechanical methods. In this article, we will explore the advantages and limitations of photochemical machining, and its applications in various industries.

Photochemical machining process

The photochemical machining process starts with a photoresist material, which is applied to a metal sheet. The photoresist is then exposed to ultra-violet light through a patterned mask called a photo-tool. The unexposed areas of the photoresist are then developed and removed before the metal sheet is sprayed with an etchant – typically ferric chloride – which chemically dissolves the exposed metal areas.

Photochemical machining advantages

Unlike traditional mechanical methods, which can create burrs or deformations on the edges of the parts, photochemical etching uses a chemical process to precisely remove the metal from the surface of the material. This results in clean edges without any burrs or mechanical stresses that can weaken the part.

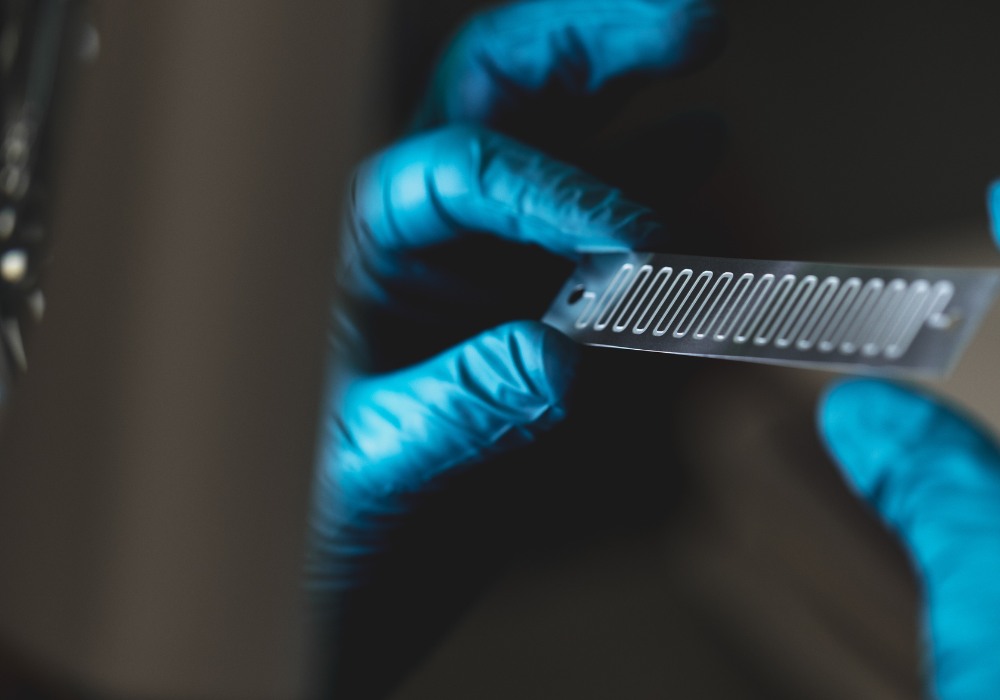

The photochemical etching process also allows for the creation of very fine features and patterns from a wide range of metals and alloys. This is because the process is entirely chemical, and the photoresist acts as a mask, allowing for very precise control over the size, shape, and tolerances of the final part.

img class=”wp-image-5074″ src=”https://www.precisionmicro.com/wp-content/uploads/2019/01/Stainless-steel-speaker-grille-etching.jpg” alt=”” />

Photochemical machining applications

Photochemical machining has a broad spectrum of high-precision metal component applications that includes:

- Precision metal shims

- Flat springs

- Lead frames

- Electrical connectors

- EMI shielding

- Filters, fluidic flow plates

- Implantable devices

These components can be produced with exceptional accuracy and consistency, without the need for expensive tooling.

Photochemical machining disadvantages

While photochemical etching offers many advantages, like any metal machining process there are also some limitations. PCM is best suited for materials that are relatively thin, typically less than 0.1 inches (2.5mm) in thickness. This means that the process may not be suitable for producing thicker parts.

The size of the parts that can be produced using PCM is also limited. This is because the size of the sheet metal is constrained by the width of the chemical etching machinery used.

Although PCM is a cost-effective and efficient process for producing high-precision parts with complex geometries quickly and cost-effectively, it may not be suitable for producing three-dimensional or simpler parts on a very large scale. This is because traditional sheet metalworking processes generally offer more favourable production times and cost per unit calculations.

Summary

Photochemical machining is an efficient and economical process for producing high-precision parts with intricate geometries rapidly and cost-effectively. It has several advantages, such as precision, versatility in materials and applications, low costs, short lead times, and clean machining outcomes. Nonetheless, the process has certain limitations, including restrictions on material thickness, size, and scalability for simpler designs. However, it remains an excellent option for many industries aiming to manufacture precise metal components with complex geometries.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download